ASSEMBLY

ASSEMBLY

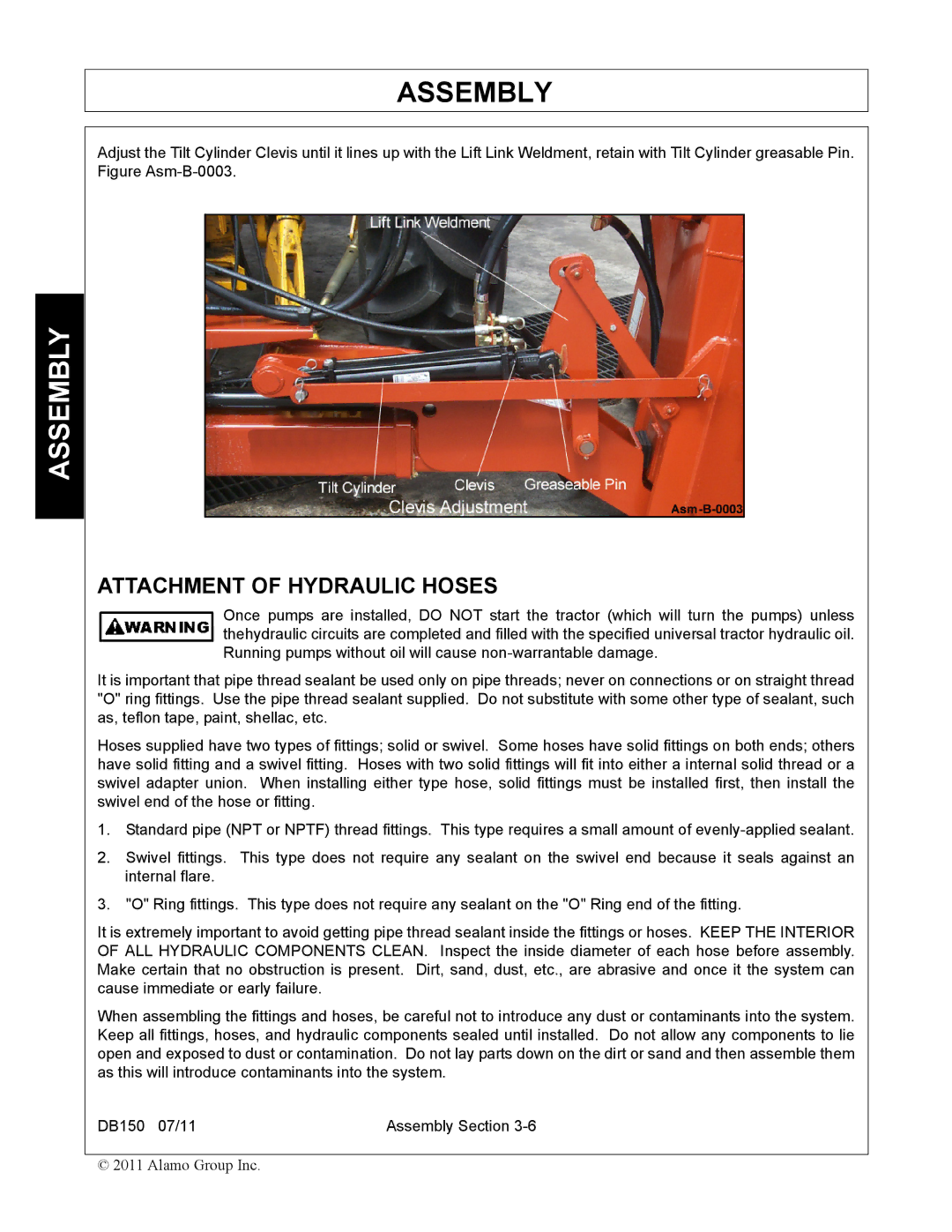

Adjust the Tilt Cylinder Clevis until it lines up with the Lift Link Weldment, retain with Tilt Cylinder greasable Pin. Figure

ATTACHMENT OF HYDRAULIC HOSES

Once pumps are installed, DO NOT start the tractor (which will turn the pumps) unless thehydraulic circuits are completed and filled with the specified universal tractor hydraulic oil. Running pumps without oil will cause

It is important that pipe thread sealant be used only on pipe threads; never on connections or on straight thread "O" ring fittings. Use the pipe thread sealant supplied. Do not substitute with some other type of sealant, such as, teflon tape, paint, shellac, etc.

Hoses supplied have two types of fittings; solid or swivel. Some hoses have solid fittings on both ends; others have solid fitting and a swivel fitting. Hoses with two solid fittings will fit into either a internal solid thread or a swivel adapter union. When installing either type hose, solid fittings must be installed first, then install the swivel end of the hose or fitting.

1.Standard pipe (NPT or NPTF) thread fittings. This type requires a small amount of

2.Swivel fittings. This type does not require any sealant on the swivel end because it seals against an internal flare.

3."O" Ring fittings. This type does not require any sealant on the "O" Ring end of the fitting.

It is extremely important to avoid getting pipe thread sealant inside the fittings or hoses. KEEP THE INTERIOR OF ALL HYDRAULIC COMPONENTS CLEAN. Inspect the inside diameter of each hose before assembly. Make certain that no obstruction is present. Dirt, sand, dust, etc., are abrasive and once it the system can cause immediate or early failure.

When assembling the fittings and hoses, be careful not to introduce any dust or contaminants into the system. Keep all fittings, hoses, and hydraulic components sealed until installed. Do not allow any components to lie open and exposed to dust or contamination. Do not lay parts down on the dirt or sand and then assemble them as this will introduce contaminants into the system.

DB150 07/11 | Assembly Section |

© 2011 Alamo Group Inc.