MAINTENANCE

MAINTENANCE

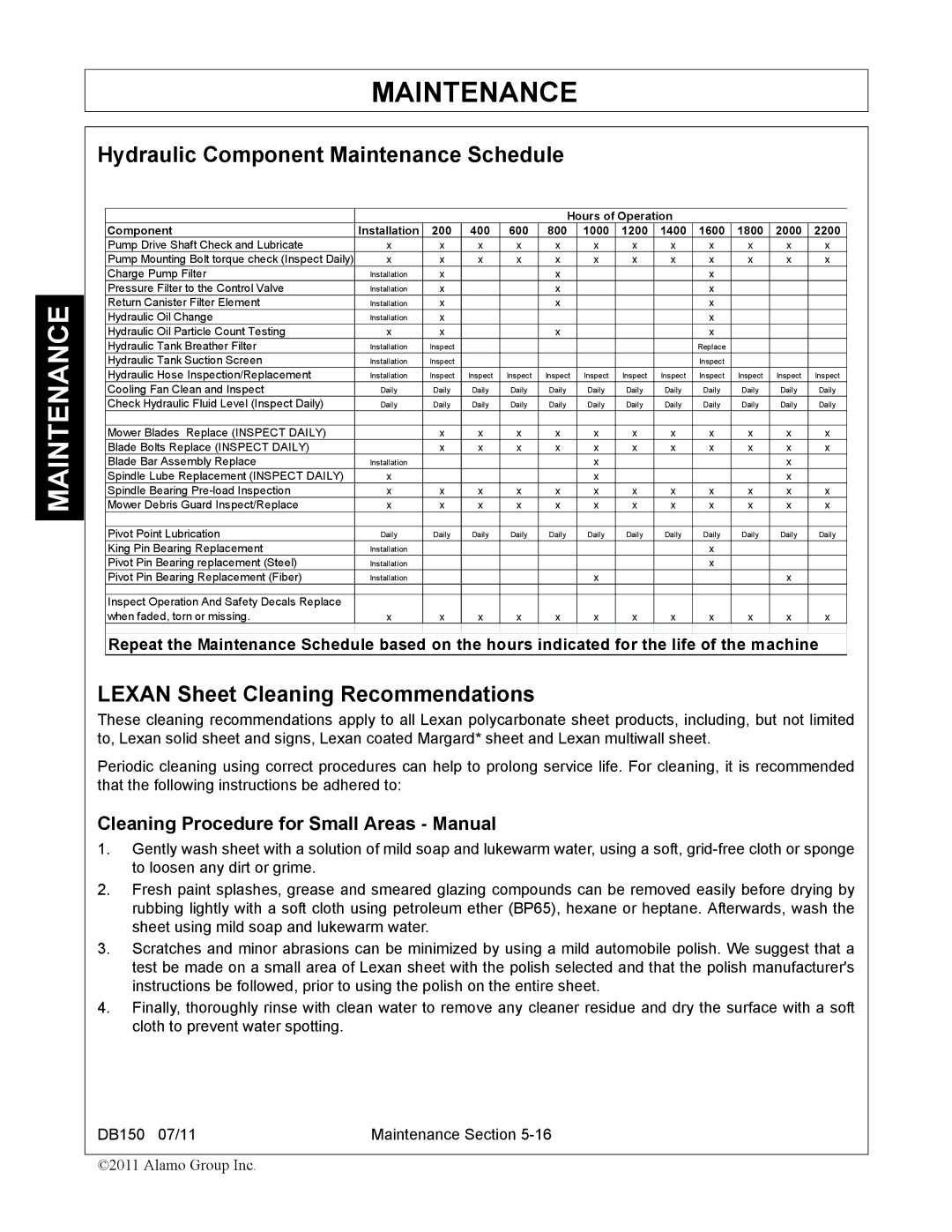

Hydraulic Component Maintenance Schedule

|

|

|

|

| Hours of Operation |

|

|

|

| |||

Component | Installation | 200 | 400 | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

Pump Drive Shaft Check and Lubricate | X | X | X | X | X | X | X | X | X | X | X | X |

Pump Mounting Bolt torque check (Inspect Daily) | X | X | X | X | X | X | X | X | X | X | X | X |

Charge Pump Filter | Installation | X |

|

| X |

|

|

| X |

|

|

|

Pressure Filter to the Control Valve | Installation | X |

|

| X |

|

|

| X |

|

|

|

Return Canister Filter Element | Installation | X |

|

| X |

|

|

| X |

|

|

|

Hydraulic Oil Change | Installation | X |

|

|

|

|

|

| X |

|

|

|

Hydraulic Oil Particle Count Testing | X | X |

|

| X |

|

|

| X |

|

|

|

Hydraulic Tank Breather Filter | Installation | Inspect |

|

|

|

|

|

| Replace |

|

|

|

Hydraulic Tank Suction Screen | Installation | Inspect |

|

|

|

|

|

| Inspect |

|

|

|

Hydraulic Hose Inspection/Replacement | Installation | Inspect | Inspect | Inspect | Inspect | Inspect | Inspect | Inspect | Inspect | Inspect | Inspect | Inspect |

Cooling Fan Clean and Inspect | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily |

Check Hydraulic Fluid Level (Inspect Daily) | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily |

|

|

|

|

|

|

|

|

|

|

|

|

|

Mower Blades Replace (INSPECT DAILY) |

| X | X | X | X | X | X | X | X | X | X | X |

Blade Bolts Replace (INSPECT DAILY) |

| X | X | X | X | X | X | X | X | X | X | X |

Blade Bar Assembly Replace | Installation |

|

|

|

| X |

|

|

|

| X |

|

Spindle Lube Replacement (INSPECT DAILY) | X |

|

|

|

| X |

|

|

|

| X |

|

Spindle Bearing | X | X | X | X | X | X | X | X | X | X | X | X |

Mower Debris Guard Inspect/Replace | X | X | X | X | X | X | X | X | X | X | X | X |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pivot Point Lubrication | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily | Daily |

King Pin Bearing Replacement | Installation |

|

|

|

|

|

|

| X |

|

|

|

Pivot Pin Bearing replacement (Steel) | Installation |

|

|

|

|

|

|

| X |

|

|

|

Pivot Pin Bearing Replacement (Fiber) | Installation |

|

|

|

| X |

|

|

|

| X |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Inspect Operation And Safety Decals Replace |

|

|

|

|

|

|

|

|

|

|

|

|

when faded, torn or missing. | X | X | X | X | X | X | X | X | X | X | X | X |

Repeat the Maintenance Schedule based on the hours indicated for the life of the machine

LEXAN Sheet Cleaning Recommendations

These cleaning recommendations apply to all Lexan polycarbonate sheet products, including, but not limited to, Lexan solid sheet and signs, Lexan coated Margard* sheet and Lexan multiwall sheet.

Periodic cleaning using correct procedures can help to prolong service life. For cleaning, it is recommended that the following instructions be adhered to:

Cleaning Procedure for Small Areas - Manual

1.Gently wash sheet with a solution of mild soap and lukewarm water, using a soft,

2.Fresh paint splashes, grease and smeared glazing compounds can be removed easily before drying by rubbing lightly with a soft cloth using petroleum ether (BP65), hexane or heptane. Afterwards, wash the sheet using mild soap and lukewarm water.

3.Scratches and minor abrasions can be minimized by using a mild automobile polish. We suggest that a test be made on a small area of Lexan sheet with the polish selected and that the polish manufacturer's instructions be followed, prior to using the polish on the entire sheet.

4.Finally, thoroughly rinse with clean water to remove any cleaner residue and dry the surface with a soft cloth to prevent water spotting.

DB150 07/11 | Maintenance Section |

©2011 Alamo Group Inc.