ASSEMBLY

ASSEMBLY

Oil Reservoir is shipped filled with oil to the minimum level. When adding hydraulic oil proceed.

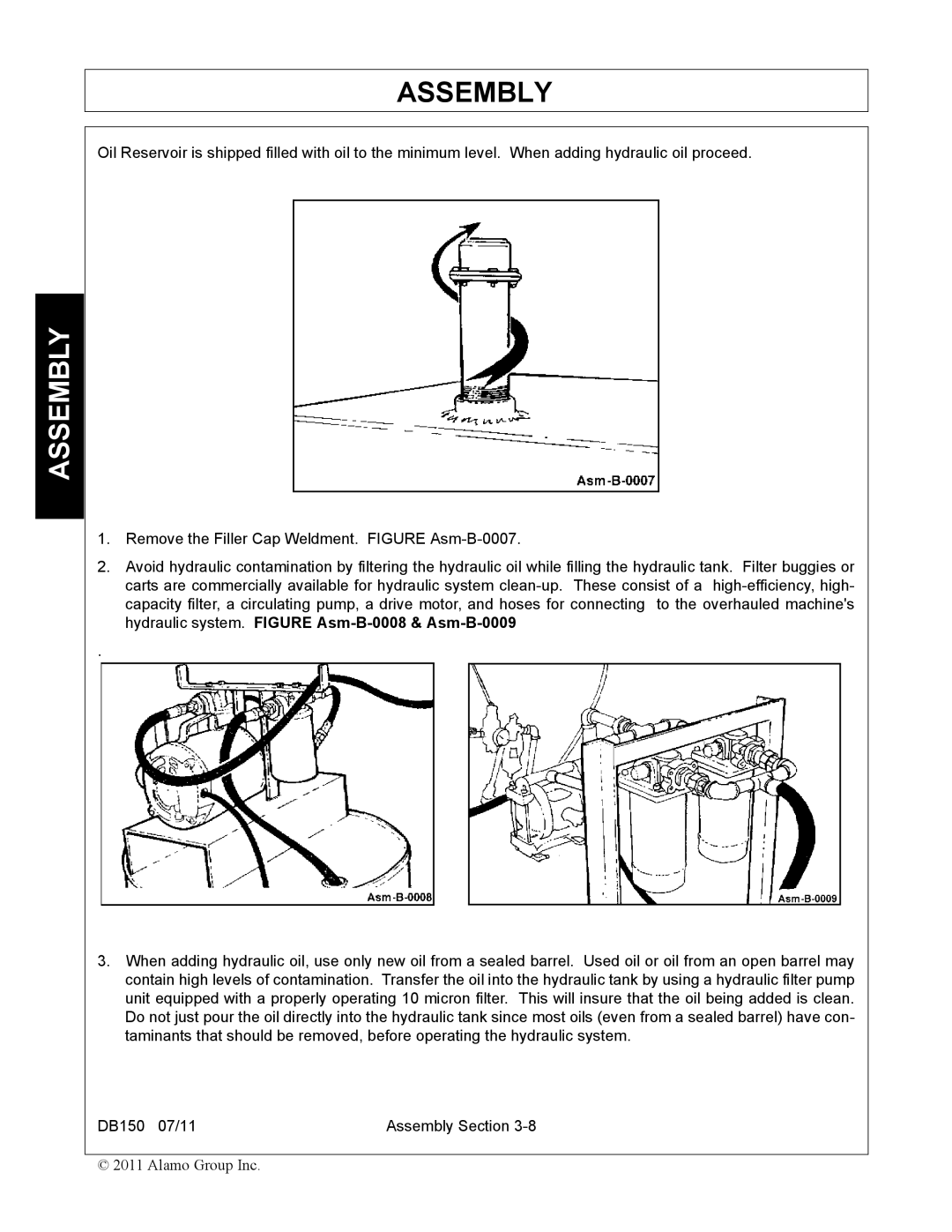

1.Remove the Filler Cap Weldment. FIGURE

2.Avoid hydraulic contamination by filtering the hydraulic oil while filling the hydraulic tank. Filter buggies or carts are commercially available for hydraulic system

.

3.When adding hydraulic oil, use only new oil from a sealed barrel. Used oil or oil from an open barrel may contain high levels of contamination. Transfer the oil into the hydraulic tank by using a hydraulic filter pump unit equipped with a properly operating 10 micron filter. This will insure that the oil being added is clean. Do not just pour the oil directly into the hydraulic tank since most oils (even from a sealed barrel) have con- taminants that should be removed, before operating the hydraulic system.

DB150 07/11 | Assembly Section |

© 2011 Alamo Group Inc.