OPERATION

OPERATION

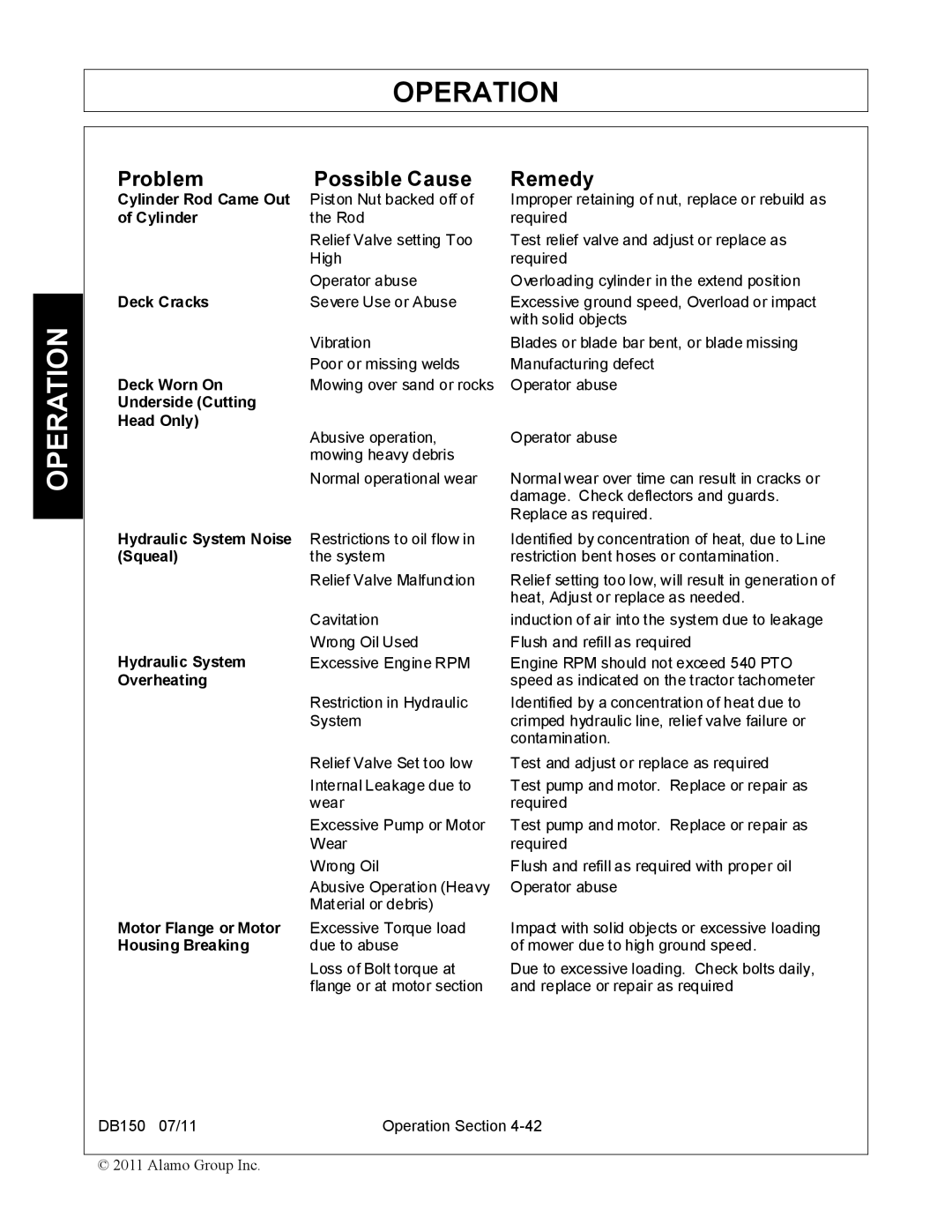

Problem | Possible Cause | Remedy |

Cylinder Rod Came Out | Piston Nut backed off of | Improper retaining of nut, replace or rebuild as |

of Cylinder | the Rod | required |

| Relief Valve setting Too | Test relief valve and adjust or replace as |

| High | required |

Deck Cracks | Operator abuse | Overloading cylinder in the extend position |

Severe Use or Abuse | Excessive ground speed, Overload or impact | |

|

| with solid objects |

| Vibration | Blades or blade bar bent, or blade missing |

Deck Worn On | Poor or missing welds | Manufacturing defect |

Mowing over sand or rocks | Operator abuse | |

Underside (Cutting |

|

|

Head Only) | Abusive operation, | Operator abuse |

| ||

| mowing heavy debris |

|

| Normal operational wear | Normal wear over time can result in cracks or |

|

| damage. Check deflectors and guards. |

|

| Replace as required. |

Hydraulic System Noise | Restrictions to oil flow in | Identified by concentration of heat, due to Line |

(Squeal) | the system | restriction bent hoses or contamination. |

| Relief Valve Malfunction | Relief setting too low, will result in generation of |

|

| heat, Adjust or replace as needed. |

| Cavitation | induction of air into the system due to leakage |

Hydraulic System | Wrong Oil Used | Flush and refill as required |

Excessive Engine RPM | Engine RPM should not exceed 540 PTO | |

Overheating |

| speed as indicated on the tractor tachometer |

| Restriction in Hydraulic | Identified by a concentration of heat due to |

| System | crimped hydraulic line, relief valve failure or |

|

| contamination. |

| Relief Valve Set too low | Test and adjust or replace as required |

| Internal Leakage due to | Test pump and motor. Replace or repair as |

| wear | required |

| Excessive Pump or Motor | Test pump and motor. Replace or repair as |

| Wear | required |

| Wrong Oil | Flush and refill as required with proper oil |

| Abusive Operation (Heavy | Operator abuse |

| Material or debris) |

|

Motor Flange or Motor | Excessive Torque load | Impact with solid objects or excessive loading |

Housing Breaking | due to abuse | of mower due to high ground speed. |

| Loss of Bolt torque at | Due to excessive loading. Check bolts daily, |

| flange or at motor section | and replace or repair as required |

DB150 07/11 | Operation Section |

© 2011 Alamo Group Inc.