OPERATION

TO USE THE MITER GAUGE

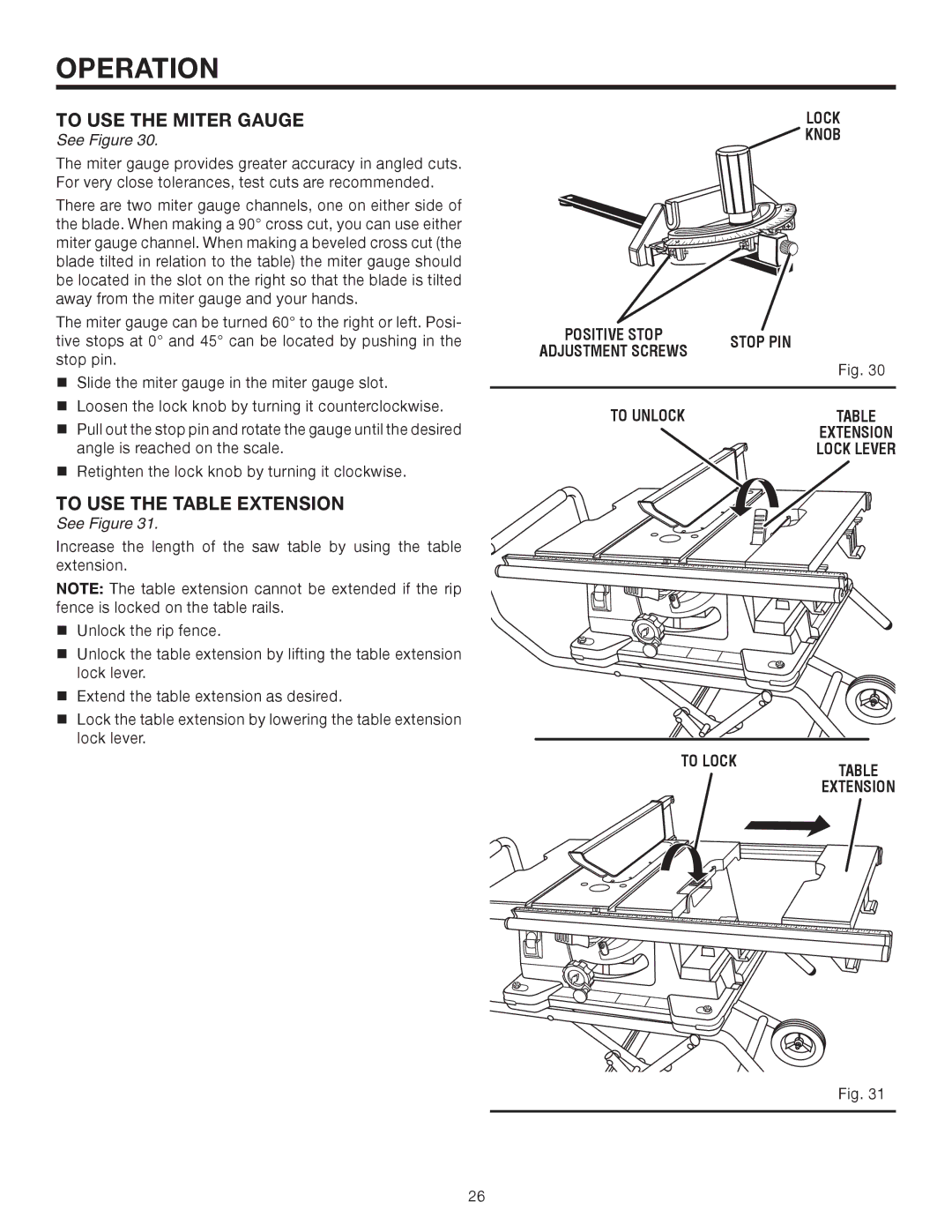

See Figure 30.

���The miter gauge provides greater accuracy in angled cuts. For very close tolerances, test cuts are recommended.

There are two miter gauge channels, one on either side of the blade. When making a 90° cross cut, you can use either miter gauge channel. When making a beveled cross cut (the blade tilted in relation to the table) the miter gauge should be located in the slot on the right so that the blade is tilted away from the miter gauge and your hands.

The miter gauge can be turned 60° to the right or left. Posi- tive stops at 0° and 45° can be located by pushing in the stop pin.

Slide the miter gauge in the miter gauge slot.

Loosen the lock knob by turning it counterclockwise.

Pull out the stop pin and rotate the gauge until the desired angle is reached on the scale.

Retighten the lock knob by turning it clockwise.

TO USE THE TABLE EXTENSION

See Figure 31.

Increase the length of the saw table by using the table extension.

NOTE: The table extension cannot be extended if the rip fence is locked on the table rails.

Unlock the rip fence.

Unlock the table extension by lifting the table extension lock lever.

Extend the table extension as desired.

Lock the table extension by lowering the table extension lock lever.

LOCK

![]() KNOB

KNOB

POSITIVE STOP | STOP PIN | |

ADJUSTMENT SCREWS | ||

| ||

| Fig. 30 | |

TO UNLOCK | TABLE | |

| EXTENSION | |

| LOCK LEVER |

TO LOCK | TABLE |

| |

| EXTENSION |

Fig. 31

26