ADJUSTMENTS

If blade is not square to the table:

Loosen 45º stop screw until it is even with the top of the saw table using 5/32 in. hex key.

Release the bevel locking lever and position the height/ bevel adjusting handwheel until blade is 45º to the table. Lock the bevel locking lever.

Screw the 45ºstop screw until the saw blade starts to move. Check again for squareness and readjust if needed.

Check bevel indicator.

If indicator is not pointing to the 45º mark on the bevel scale, loosen the indicator adjusting screw and adjust indicator.

Retighten screw.

To set the bevel indicator:

With the saw blade at 0º, the bevel indicator should be pointing to 0º.

If not, loosen the indicator adjusting screw and adjust indicator.

Retighten screw.

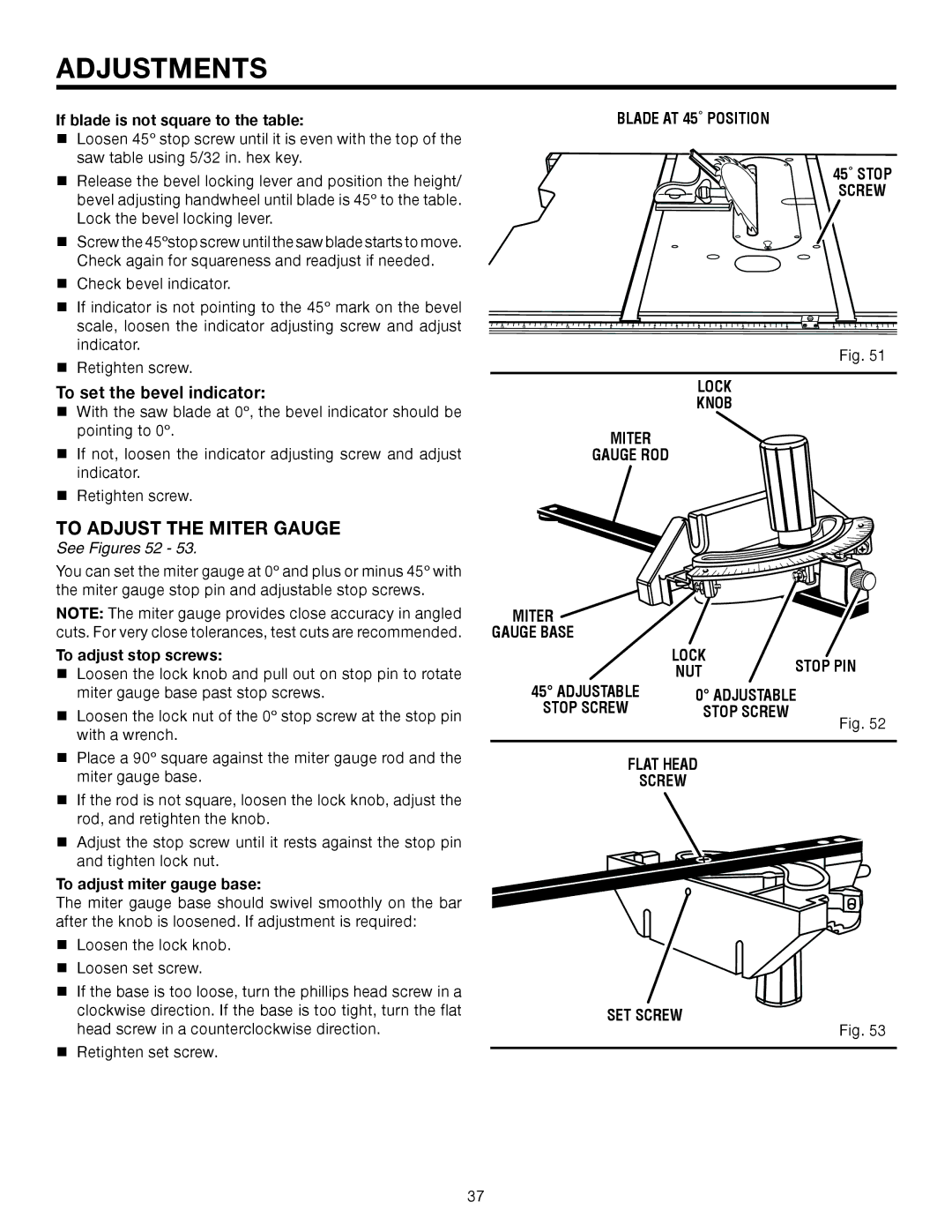

TO ADJUST THE MITER GAUGE

See Figures 52 - 53.

You can set the miter gauge at 0º and plus or minus 45º with the miter gauge stop pin and adjustable stop screws.

NOTE: The miter gauge provides close accuracy in angled cuts. For very close tolerances, test cuts are recommended.

To adjust stop screws:

Loosen the lock knob and pull out on stop pin to rotate miter gauge base past stop screws.

Loosen the lock nut of the 0º stop screw at the stop pin with a wrench.

Place a 90º square against the miter gauge rod and the miter gauge base.

If the rod is not square, loosen the lock knob, adjust the rod, and retighten the knob.

Adjust the stop screw until it rests against the stop pin and tighten lock nut.

To adjust miter gauge base:

The miter gauge base should swivel smoothly on the bar after the knob is loosened. If adjustment is required:

Loosen the lock knob.

Loosen set screw.

If the base is too loose, turn the phillips head screw in a clockwise direction. If the base is too tight, turn the flat head screw in a counterclockwise direction.

Retighten set screw.

BLADE AT 45˚ POSITION

45˚ STOP

SCREW

Fig. 51

LOCK

KNOB

MITER

GAUGE ROD

MITER |

| |

GAUGE BASE |

| |

LOCK | STOP PIN | |

NUT | ||

|

45° ADJUSTABLE | 0° ADJUSTABLE |

|

STOP SCREW | STOP SCREW | Fig. 52 |

|

| |

|

|

|

FLAT HEAD

SCREW

SET SCREW

Fig. 53

37