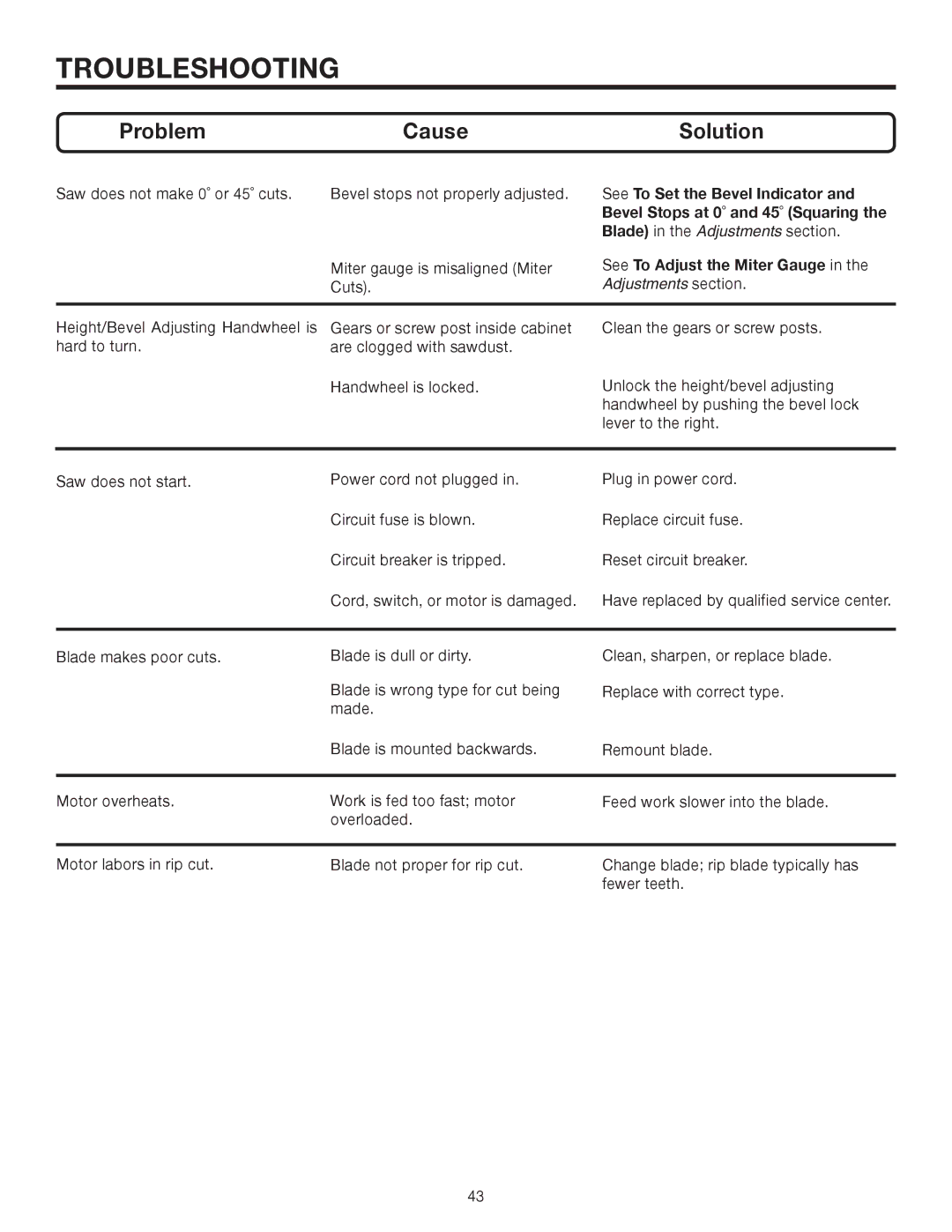

TROUBLESHOOTING

Problem | Cause | Solution |

Saw does not make 0˚ or 45˚ cuts. | Bevel stops not properly adjusted. | See To Set the Bevel Indicator and |

|

| Bevel Stops at 0˚ and 45˚ (Squaring the |

|

| Blade) in the Adjustments section. |

| Miter gauge is misaligned (Miter | See To Adjust the Miter Gauge in the |

| Cuts). | Adjustments section. |

|

|

|

Height/Bevel Adjusting Handwheel is hard to turn.

Saw does not start.

Gears or screw post inside cabinet | Clean the gears or screw posts. |

are clogged with sawdust. |

|

Handwheel is locked. | Unlock the height/bevel adjusting |

| handwheel by pushing the bevel lock |

| lever to the right. |

Power cord not plugged in. | Plug in power cord. |

Circuit fuse is blown. | Replace circuit fuse. |

Circuit breaker is tripped. | Reset circuit breaker. |

Cord, switch, or motor is damaged. | Have replaced by qualified service center. |

Blade makes poor cuts. | Blade is dull or dirty. |

| Blade is wrong type for cut being |

| made. |

| Blade is mounted backwards. |

Clean, sharpen, or replace blade. Replace with correct type.

Remount blade.

Motor overheats. | Work is fed too fast; motor |

| overloaded. |

Feed work slower into the blade.

Motor labors in rip cut. | Blade not proper for rip cut. |

Change blade; rip blade typically has fewer teeth.

43