MAINTENANCE

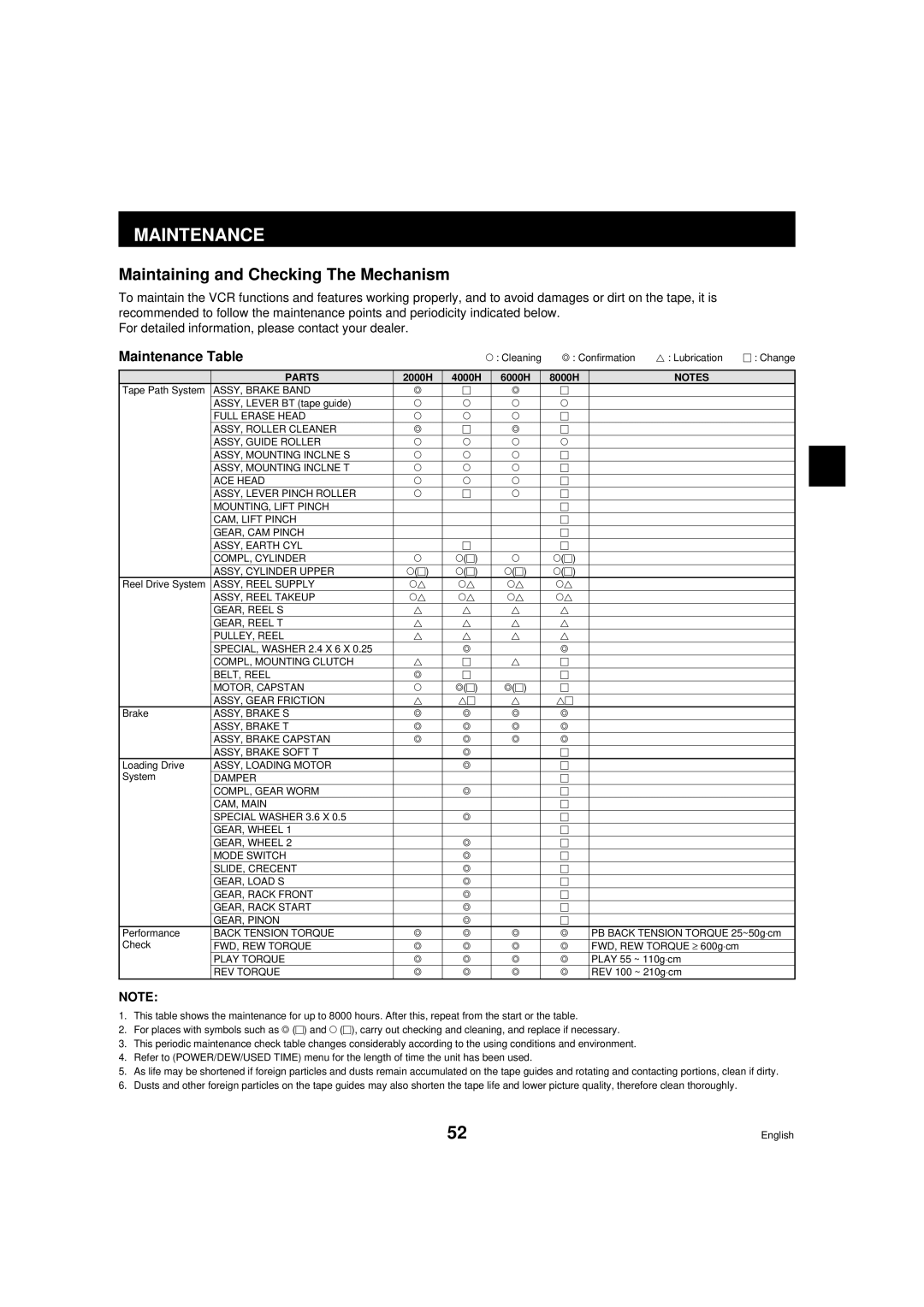

Maintaining and Checking The Mechanism

To maintain the VCR functions and features working properly, and to avoid damages or dirt on the tape, it is recommended to follow the maintenance points and periodicity indicated below.

For detailed information, please contact your dealer.

Maintenance Table

F : Cleaning E : Confirmation v : Lubrication k : Change

| PARTS | 2000H | 4000H | 6000H | 8000H | NOTES | ||

Tape Path System | ASSY, BRAKE BAND | E | k | E | k |

|

|

|

| ASSY, LEVER BT (tape guide) | F | F | F | F |

|

|

|

| FULL ERASE HEAD | F | F | F | k |

|

|

|

| ASSY, ROLLER CLEANER | E | k | E | k |

|

|

|

| ASSY, GUIDE ROLLER | F | F | F | F |

|

|

|

| ASSY, MOUNTING INCLNE S | F | F | F | k |

|

|

|

| ASSY, MOUNTING INCLNE T | F | F | F | k |

|

|

|

| ACE HEAD | F | F | F | k |

|

|

|

| ASSY, LEVER PINCH ROLLER | F | k | F | k |

|

|

|

| MOUNTING, LIFT PINCH |

|

|

| k |

|

|

|

| CAM, LIFT PINCH |

|

|

| k |

|

|

|

| GEAR, CAM PINCH |

|

|

| k |

|

|

|

| ASSY, EARTH CYL |

| k |

| k |

|

|

|

| COMPL, CYLINDER | F | F(k) | F | F(k) |

|

|

|

| ASSY, CYLINDER UPPER | F(k) | F(k) | F(k) | F(k) |

|

|

|

Reel Drive System | ASSY, REEL SUPPLY | Fv | Fv | Fv | Fv |

|

|

|

| ASSY, REEL TAKEUP | Fv | Fv | Fv | Fv |

|

|

|

| GEAR, REEL S | v | v | v | v |

|

|

|

| GEAR, REEL T | v | v | v | v |

|

|

|

| PULLEY, REEL | v | v | v | v |

|

|

|

| SPECIAL, WASHER 2.4 X 6 X 0.25 |

| E |

| E |

|

|

|

| COMPL, MOUNTING CLUTCH | v | k | v | k |

|

|

|

| BELT, REEL | E | k |

| k |

|

|

|

| MOTOR, CAPSTAN | F | E(k) | E(k) | k |

|

|

|

| ASSY, GEAR FRICTION | v | vk | v | vk |

|

|

|

Brake | ASSY, BRAKE S | E | E | E | E |

|

|

|

| ASSY, BRAKE T | E | E | E | E |

|

|

|

| ASSY, BRAKE CAPSTAN | E | E | E | E |

|

|

|

| ASSY, BRAKE SOFT T |

| E |

| k |

|

|

|

Loading Drive | ASSY, LOADING MOTOR |

| E |

| k |

|

|

|

System | DAMPER |

|

|

| k |

|

|

|

| COMPL, GEAR WORM |

| E |

| k |

|

|

|

| CAM, MAIN |

|

|

| k |

|

|

|

| SPECIAL WASHER 3.6 X 0.5 |

| E |

| k |

|

|

|

| GEAR, WHEEL 1 |

|

|

| k |

|

|

|

| GEAR, WHEEL 2 |

| E |

| k |

|

|

|

| MODE SWITCH |

| E |

| k |

|

|

|

| SLIDE, CRECENT |

| E |

| k |

|

|

|

| GEAR, LOAD S |

| E |

| k |

|

|

|

| GEAR, RACK FRONT |

| E |

| k |

|

|

|

| GEAR, RACK START |

| E |

| k |

|

|

|

| GEAR, PINON |

| E |

| k |

|

|

|

Performance | BACK TENSION TORQUE | E | E | E | E | PB BACK TENSION TORQUE 25~50g⋅cm | ||

Check | FWD, REW TORQUE | E | E | E | E | FWD, REW TORQUE | ≥ | ⋅ |

|

| 600g cm | ||||||

| PLAY TORQUE | E | E | E | E | PLAY 55 ~ 110g⋅cm |

|

|

| REV TORQUE | E | E | E | E | REV 100 ~ 210g⋅cm |

|

|

NOTE:

1.This table shows the maintenance for up to 8000 hours. After this, repeat from the start or the table.

2.For places with symbols such as E (k) and F (k), carry out checking and cleaning, and replace if necessary.

3.This periodic maintenance check table changes considerably according to the using conditions and environment.

4.Refer to (POWER/DEW/USED TIME) menu for the length of time the unit has been used.

5.As life may be shortened if foreign particles and dusts remain accumulated on the tape guides and rotating and contacting portions, clean if dirty.

6.Dusts and other foreign particles on the tape guides may also shorten the tape life and lower picture quality, therefore clean thoroughly.

52 | English |