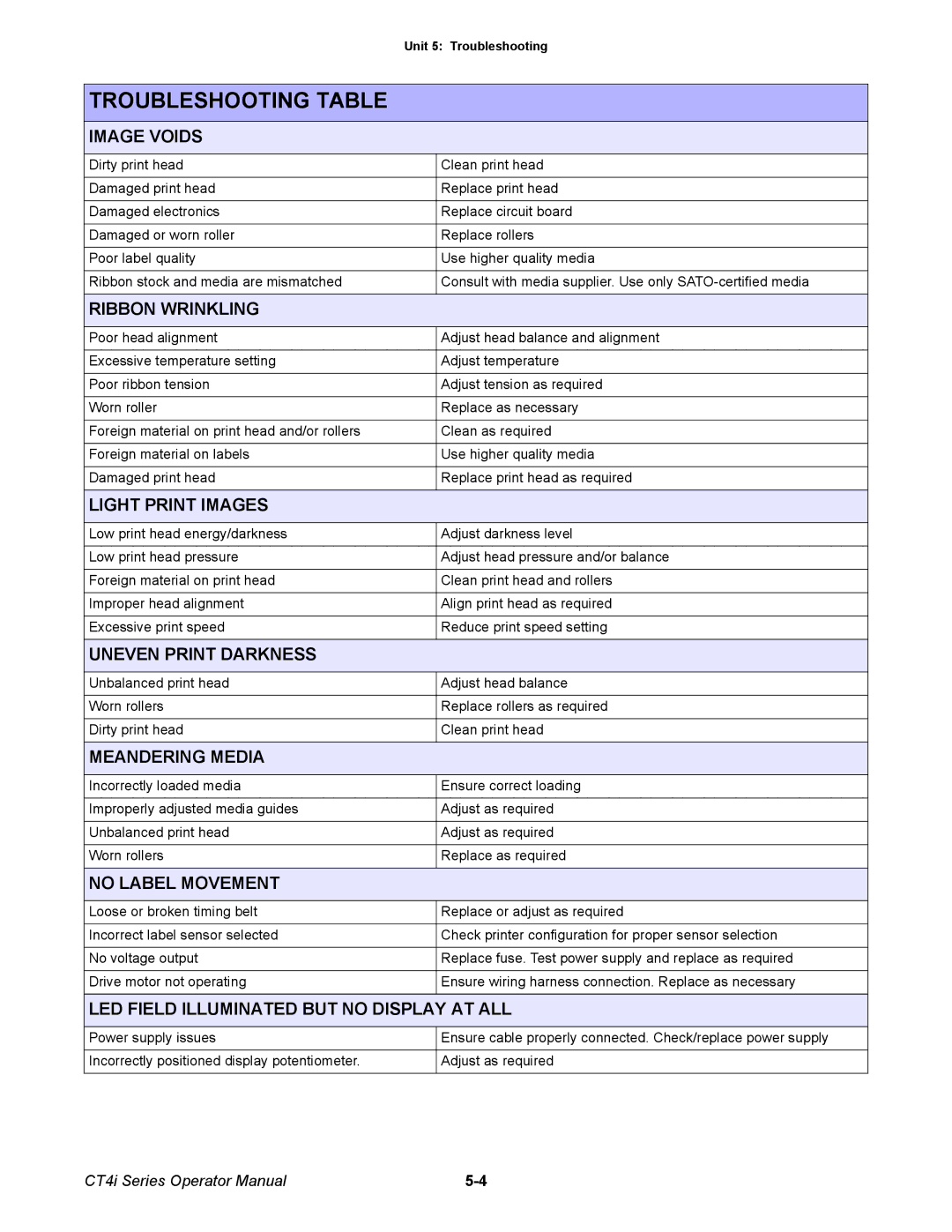

| Unit 5: Troubleshooting | |

|

|

|

TROUBLESHOOTING TABLE |

|

|

|

|

|

IMAGE VOIDS |

|

|

|

|

|

Dirty print head |

| Clean print head |

|

|

|

Damaged print head |

| Replace print head |

|

|

|

Damaged electronics |

| Replace circuit board |

|

|

|

Damaged or worn roller |

| Replace rollers |

|

|

|

Poor label quality |

| Use higher quality media |

|

|

|

Ribbon stock and media are mismatched |

| Consult with media supplier. Use only |

|

|

|

RIBBON WRINKLING |

|

|

|

|

|

Poor head alignment |

| Adjust head balance and alignment |

|

|

|

Excessive temperature setting |

| Adjust temperature |

|

|

|

Poor ribbon tension |

| Adjust tension as required |

|

|

|

Worn roller |

| Replace as necessary |

|

|

|

Foreign material on print head and/or rollers |

| Clean as required |

|

|

|

Foreign material on labels |

| Use higher quality media |

|

|

|

Damaged print head |

| Replace print head as required |

|

|

|

LIGHT PRINT IMAGES |

|

|

|

|

|

Low print head energy/darkness |

| Adjust darkness level |

|

|

|

Low print head pressure |

| Adjust head pressure and/or balance |

|

|

|

Foreign material on print head |

| Clean print head and rollers |

|

|

|

Improper head alignment |

| Align print head as required |

|

|

|

Excessive print speed |

| Reduce print speed setting |

|

|

|

UNEVEN PRINT DARKNESS |

|

|

|

|

|

Unbalanced print head |

| Adjust head balance |

|

|

|

Worn rollers |

| Replace rollers as required |

|

|

|

Dirty print head |

| Clean print head |

|

|

|

MEANDERING MEDIA |

|

|

|

|

|

Incorrectly loaded media |

| Ensure correct loading |

|

|

|

Improperly adjusted media guides |

| Adjust as required |

|

|

|

Unbalanced print head |

| Adjust as required |

|

|

|

Worn rollers |

| Replace as required |

|

|

|

NO LABEL MOVEMENT |

|

|

|

|

|

Loose or broken timing belt |

| Replace or adjust as required |

|

|

|

Incorrect label sensor selected |

| Check printer configuration for proper sensor selection |

|

|

|

No voltage output |

| Replace fuse. Test power supply and replace as required |

|

|

|

Drive motor not operating |

| Ensure wiring harness connection. Replace as necessary |

|

| |

LED FIELD ILLUMINATED BUT NO DISPLAY AT ALL | ||

|

|

|

Power supply issues |

| Ensure cable properly connected. Check/replace power supply |

|

|

|

Incorrectly positioned display potentiometer. |

| Adjust as required |

|

|

|

CT4i Series Operator Manual |