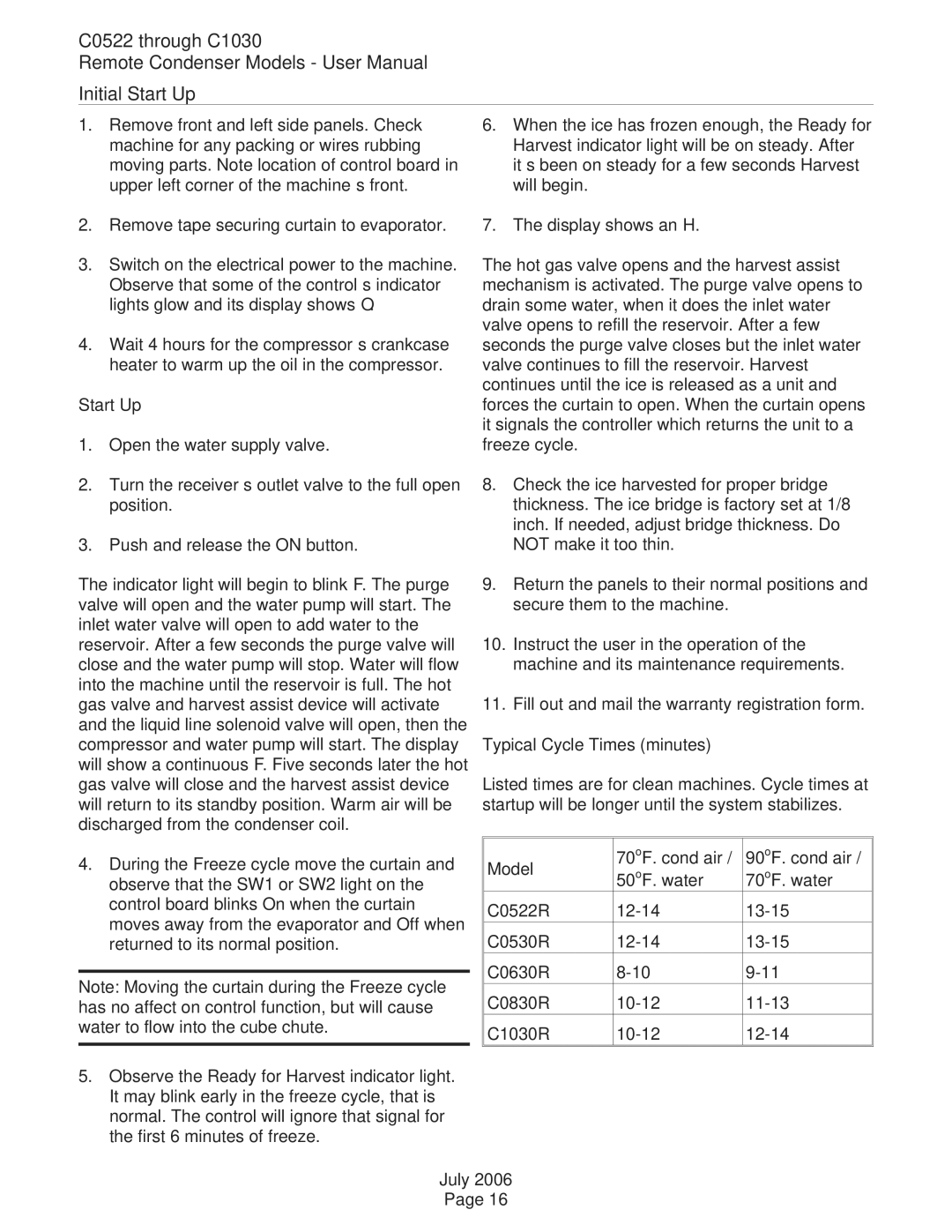

C0630, C1030, C0830, C0530, C0522 specifications

The Scotsman Ice machine models C0530, C0830, and C0330 are renowned for their reliability and efficiency in ice production, making them a preferred choice for various commercial settings. These models are known for their capability to produce high-quality cube ice, which is essential for bars, restaurants, and hotels.One of the main features of the Scotsman C0530, C0830, and C0330 is their advanced ice-making technology. These machines utilize a unique harvest assist mechanism that ensures quick and efficient production of ice. By using a simple yet effective system, these models can produce ice faster than traditional ice machines, reducing downtime and maximizing productivity. This technology not only enhances output but also minimizes energy consumption, making them eco-friendly choices for businesses looking to reduce their carbon footprint.

The C0530 model is designed to produce around 500 pounds of ice per day, while the C0830 can yield up to 800 pounds, catering to varying demands in a busy commercial environment. On the other hand, the C0330 is a compact version that offers around 300 pounds of daily production, making it ideal for establishments with less intensive ice needs. Each model is designed with a strong focus on efficiency and ease of use.

These machines are equipped with integral features aimed at simplicity and durability. Scotsman's modular design allows for easy installation, maintenance, and operation. Furthermore, the C0530, C0830, and C0330 come with a reliable water filtration system, ensuring that the ice produced is crystal clear and tastes pure.

Another critical characteristic of these ice machines is their stainless-steel construction, which enhances their durability and resistance to corrosion. This makes them suitable for high-demand environments where reliability is paramount.

Moreover, Scotsman has integrated energy-efficient components into these models, helping operators to save on utility costs while providing consistent ice production. With automated controls, these machines reduce the need for manual intervention, ensuring that ice is readily available when needed.

In conclusion, the Scotsman Ice machines C0530, C0830, and C0330 stand out in the commercial ice-making market due to their advanced technology, efficient ice production, and user-friendly features. Their robust design, coupled with energy-saving attributes, ensures that businesses can rely on these machines for consistent ice supply, enhancing overall service quality.