If b! ade is NOT 45 ° to | table.., the | 45 ° STOP COLLAR |

|

|

and SCALE must be ADJUSTED, |

| _ |

| |

1 Remove Elevation | Handwheel. | _ | 0 | ° |

2.Using a small size screwdriver, reach thru curved slot in front trim panel and loosen BOTH setscrews in 45 ° STOP COLLAR.

3.ROTATE the STOP COLLAR moving it IN or OUT

| TILTNOTE:theHANDWHEELs,,ght,y'fY°ucan't reach .the setscrews'turn | __ | _i! | _ | ||||

| and TILT | blade RIGHT or LEFT... | checking with |

|

|

|

| |

| your square until blade is 45 ° to table. |

|

|

|

| |||

4. | NOTE: If you can't reach the setscrews, turn TILT | ___l_ |

|

| ||||

TIGHTEN | the setscrews. |

|

|

| ||||

| HANDWHEEL | slightly. |

|

|

|

|

| |

5. | Loosen two | screws on scale and | adjust scale until | _ | \ | \ | ||

| POINTER | points to 45 ° mark. |

|

|

| / | ||

6.Install Elevation Handwheel.

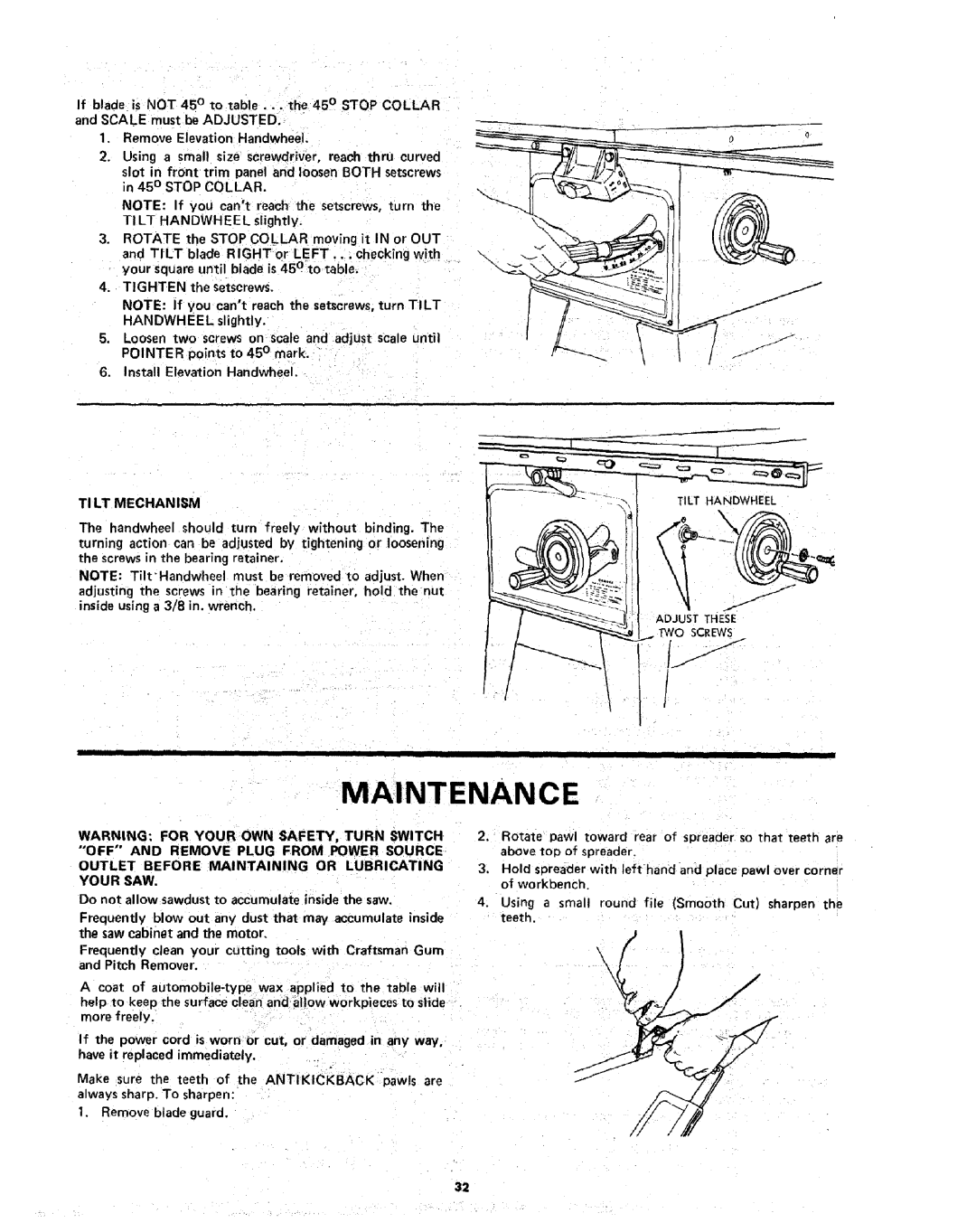

TI LT MECHANISM

The handwheel should turn freely without binding. The turning action can be adjusted by tightening or loosening the screws in the bearing retainer.

NOTE: Tilt'Handwheel must be removed to adjust. When adjusting the screws in the bearing retainer, hold the nut inside using a 3/8 in. wrench.

/ | t | iO | SCREWS |

I | II | IIII | IIIII |

MAINTENANCE

WARNING: FOR YOUR OWN SAFETY, TURN SWITCH "OFF" AND REMOVE PLUG FROM POWER SOURCE

OUTLET BEFORE MAINTAINING OR LUBRICATING

YOUR SAW.

Do not allow sawdust to accumulate inside the saw.

Frequently blow out any dust that may accumulate inside the saw cabinet and the motor.

Frequently clean your cutting tools with Craftsman Gum and Pitch Remover.

A coat of

If the power cord is worn or cut, or damaged in any way. have it replaced immediately.

Make sure the teeth of the ANTIKICKBACK pawls are always sharp. To sharpen:

1.Remove blade guard.

2.Rotate pawl toward rear of spreader so that teeth are above top of spreader.

3.Hold spreader with left hand and place pawl over corner of workbench.

4.Using a small round file (Smooth Cut) sharpen the teeth

,)

32