Jaguar Model |

| 37 | |||

IV. CHECK COMBUSTION AND FUEL INPUT RATE | 2. If the CO2 is not 0.2% at the low firing rate, then the |

| |||

A. Start and run the burner at the high firing rate, by using the |

| gas valve needs to be accessed for proper adjust- | |||

| ment. Remove the boiler jacket top cover, 3 front | ||||

“System Test” mode in the “View and changing system |

| ||||

| cover panels, and enclosure front cover (see figure 2 | ||||

setting” menu. Refer to Table 5 on page 33. |

| ||||

| on page 3 for locations. | ||||

|

|

| |||

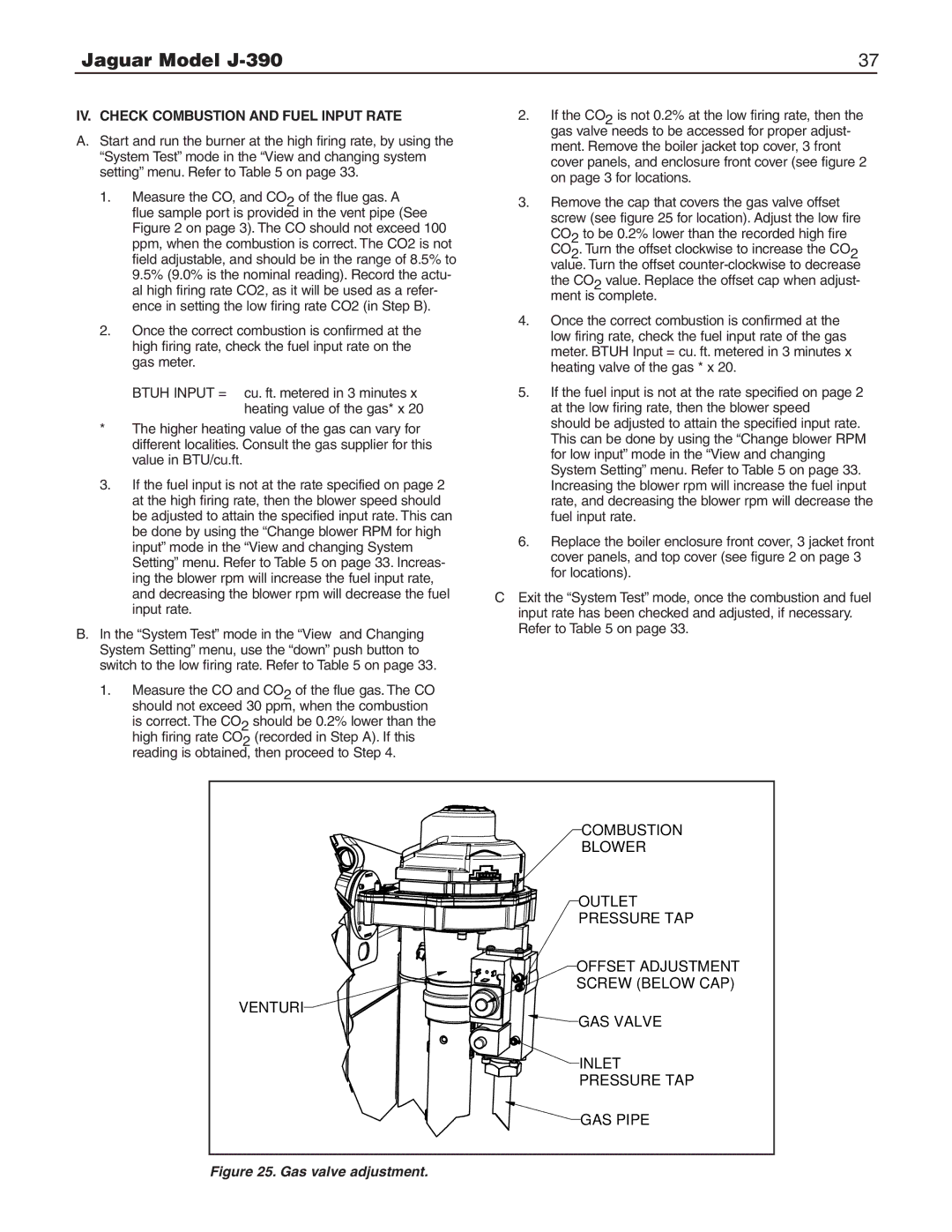

1. | Measure the CO, and CO2 of the flue gas. A | 3. Remove the cap that covers the gas valve offset | |||

| flue sample port is provided in the vent pipe (See |

| screw (see figure 25 for location). Adjust the low fire | ||

| Figure 2 on page 3). The CO should not exceed 100 |

| |||

|

| CO2 to be 0.2% lower than the recorded high fire | |||

| ppm, when the combustion is correct. The CO2 is not |

| |||

|

| CO2. Turn the offset clockwise to increase the CO2 | |||

| field adjustable, and should be in the range of 8.5% to |

| |||

|

| value. Turn the offset | |||

| 9.5% (9.0% is the nominal reading). Record the actu- |

| |||

|

| the CO2 value. Replace the offset cap when adjust- | |||

| al high firing rate CO2, as it will be used as a refer- |

| |||

|

| ment is complete. | |||

| ence in setting the low firing rate CO2 (in Step B). |

| |||

| 4. | Once the correct combustion is confirmed at the | |||

2. | Once the correct combustion is confirmed at the | ||||

| low firing rate, check the fuel input rate of the gas | ||||

| high firing rate, check the fuel input rate on the |

| |||

|

| meter. BTUH Input = cu. ft. metered in 3 minutes x | |||

| gas meter. |

| |||

|

| heating valve of the gas * x 20. | |||

|

|

| |||

| BTUH INPUT = cu. ft. metered in 3 minutes x | 5. If the fuel input is not at the rate specified on page 2 | |||

| heating value of the gas* x 20 |

| at the low firing rate, then the blower speed | ||

* | The higher heating value of the gas can vary for |

| should be adjusted to attain the specified input rate. | ||

| This can be done by using the “Change blower RPM | ||||

| different localities. Consult the gas supplier for this |

| |||

|

| for low input” mode in the “View and changing | |||

| value in BTU/cu.ft. |

| |||

|

| System Setting” menu. Refer to Table 5 on page 33. | |||

3. | If the fuel input is not at the rate specified on page 2 |

| |||

| Increasing the blower rpm will increase the fuel input | ||||

| at the high firing rate, then the blower speed should |

| rate, and decreasing the blower rpm will decrease the | ||

| be adjusted to attain the specified input rate. This can |

| fuel input rate. | ||

| be done by using the “Change blower RPM for high | 6. | Replace the boiler enclosure front cover, 3 jacket front | ||

| input” mode in the “View and changing System | ||||

|

| cover panels, and top cover (see figure 2 on page 3 | |||

| Setting” menu. Refer to Table 5 on page 33. Increas- |

| |||

|

| for locations). | |||

| ing the blower rpm will increase the fuel input rate, |

| |||

|

|

|

| ||

| and decreasing the blower rpm will decrease the fuel | C Exit the “System Test” mode, once the combustion and fuel | |||

| input rate. | input rate has been checked and adjusted, if necessary. | |||

B. In the “System Test” mode in the “View and Changing | Refer to Table 5 on page 33. |

| |

System Setting” menu, use the “down” push button to |

|

switch to the low firing rate. Refer to Table 5 on page 33. |

|

1.Measure the CO and CO2 of the flue gas. The CO should not exceed 30 ppm, when the combustion

is correct. The CO2 should be 0.2% lower than the high firing rate CO2 (recorded in Step A). If this reading is obtained, then proceed to Step 4.

COMBUSTION |

BLOWER |

OUTLET |

PRESSURE TAP |

OFFSET ADJUSTMENT |

SCREW (BELOW CAP) |

VENTURI |

GAS VALVE |

INLET |

PRESSURE TAP |

GAS PIPE |