Jaguar Model | 9 |

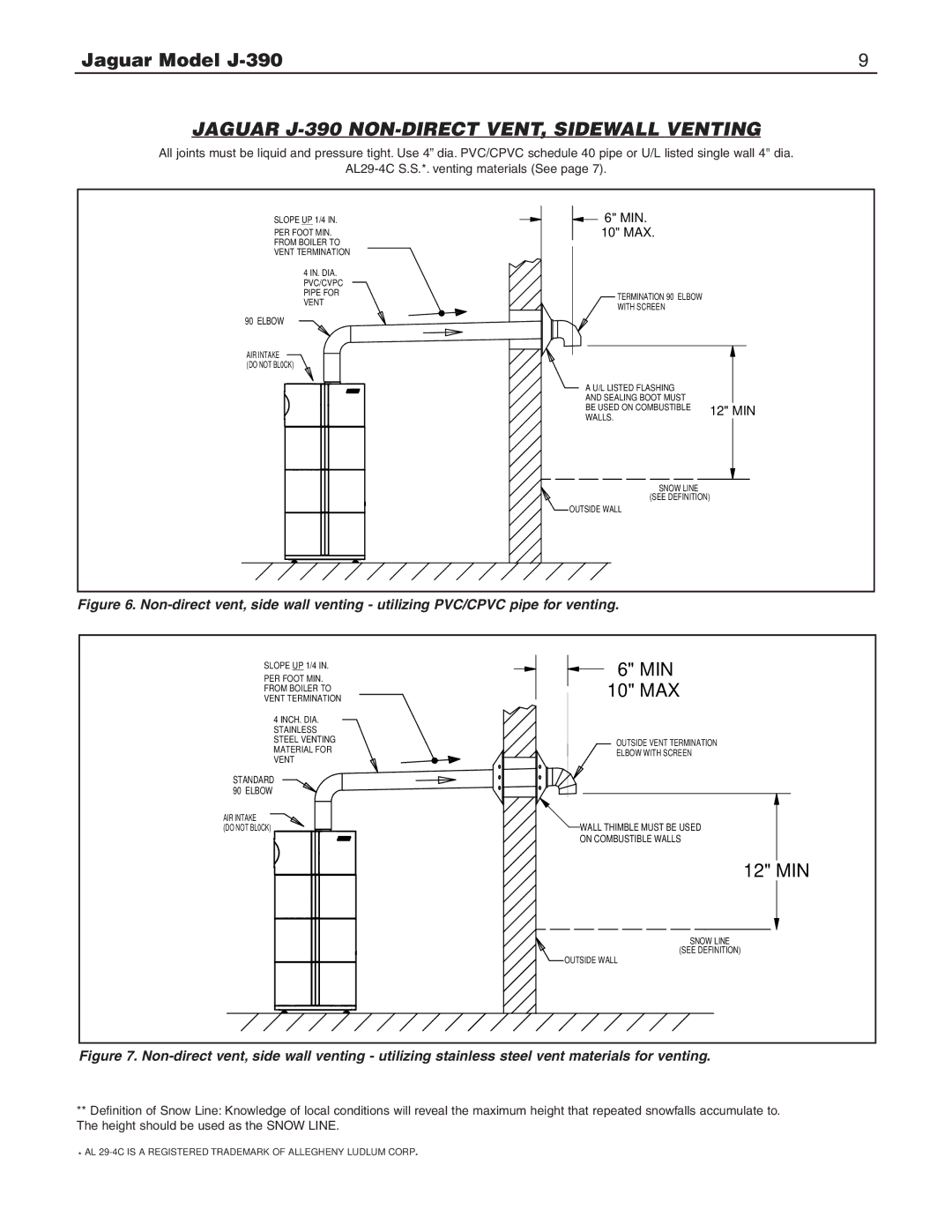

JAGUAR J-390 NON-DIRECT VENT, SIDEWALL VENTING

All joints must be liquid and pressure tight. Use 4” dia. PVC/CPVC schedule 40 pipe or U/L listed single wall 4" dia.

|

| |

SLOPE UP 1/4 IN. | 6" MIN. |

|

PER FOOT MIN. | 10" MAX. |

|

FROM BOILER TO |

|

|

VENT TERMINATION |

| |

4 IN. DIA. |

|

|

PVC/CVPC |

|

|

PIPE FOR | TERMINATION 90 ELBOW |

|

VENT |

| |

WITH SCREEN |

| |

|

| |

90 ELBOW |

|

|

AIR INTAKE |

|

|

(DO NOT BL0CK) |

|

|

| A U/L LISTED FLASHING |

|

| AND SEALING BOOT MUST |

|

| BE USED ON COMBUSTIBLE | 12" MIN |

| WALLS. | |

|

| |

| SNOW LINE |

|

| (SEE DEFINITION) | |

| OUTSIDE WALL |

|

Figure 6. Non-direct vent, side wall venting - utilizing PVC/CPVC pipe for venting.

SLOPE UP 1/4 IN.

PER FOOT MIN. FROM BOILER TO VENT TERMINATION

6" MIN 10" MAX

6" MIN 10" MAX

4 INCH. DIA. |

| |

STAINLESS |

| |

STEEL VENTING | OUTSIDE VENT TERMINATION | |

MATERIAL FOR | ||

ELBOW WITH SCREEN | ||

VENT | ||

| ||

STANDARD |

| |

90 ELBOW |

| |

AIR INTAKE |

| |

(DO NOT BL0CK) | WALL THIMBLE MUST BE USED | |

| ON COMBUSTIBLE WALLS | |

| 12" MIN | |

| SNOW LINE | |

| (SEE DEFINITION) | |

| OUTSIDE WALL |

Figure 7. Non-direct vent, side wall venting - utilizing stainless steel vent materials for venting.

**Definition of Snow Line: Knowledge of local conditions will reveal the maximum height that repeated snowfalls accumulate to. The height should be used as the SNOW LINE.

* AL