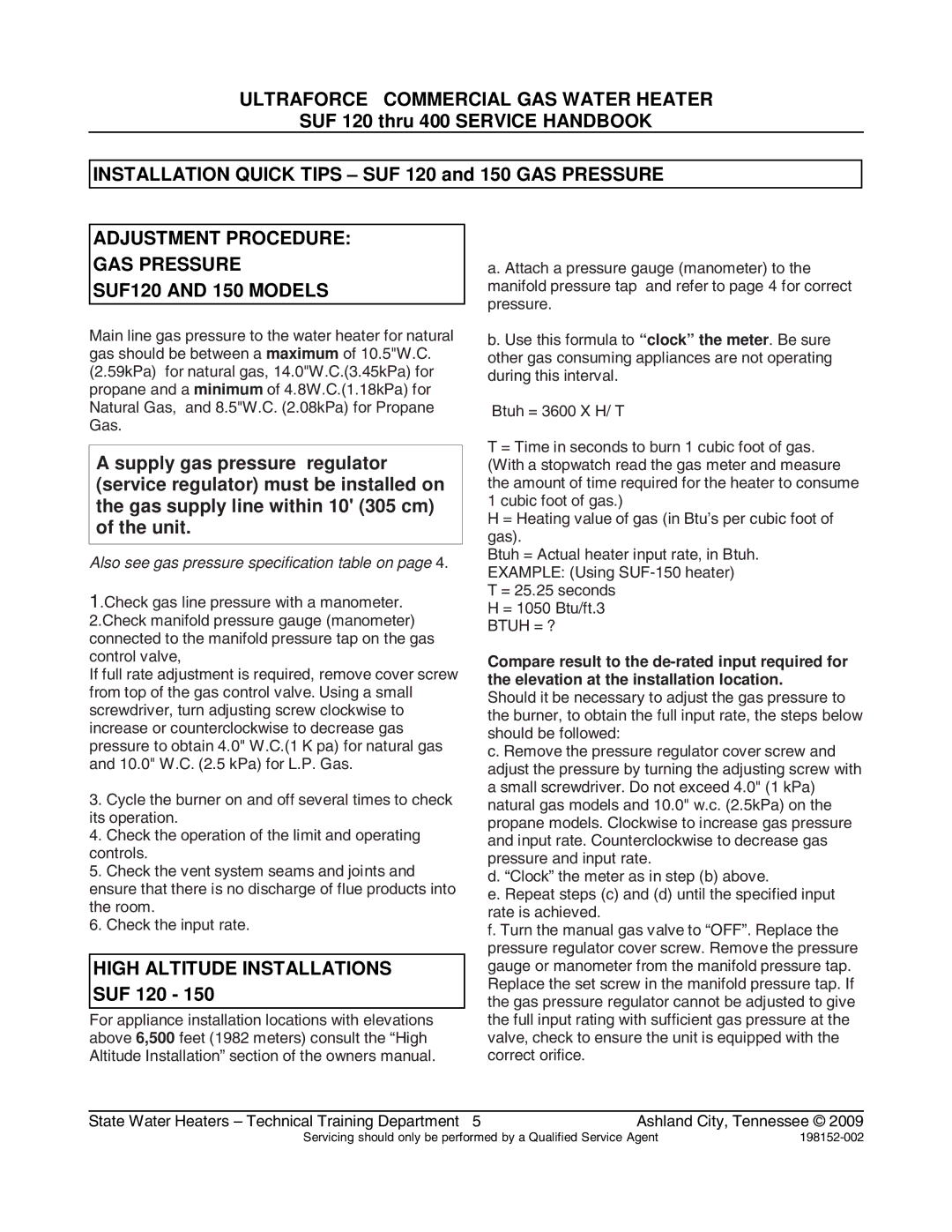

ULTRAFORCE COMMERCIAL GAS WATER HEATER

SUF 120 thru 400 SERVICE HANDBOOK

INSTALLATION QUICK TIPS – SUF 120 and 150 GAS PRESSURE

ADJUSTMENT PROCEDURE:

GAS PRESSURE

SUF120 AND 150 MODELS

Main line gas pressure to the water heater for natural gas should be between a maximum of 10.5"W.C. (2.59kPa) for natural gas, 14.0"W.C.(3.45kPa) for propane and a minimum of 4.8W.C.(1.18kPa) for Natural Gas, and 8.5"W.C. (2.08kPa) for Propane Gas.

A supply gas pressure regulator (service regulator) must be installed on the gas supply line within 10' (305 cm) of the unit.

Also see gas pressure specification table on page 4.

1.Check gas line pressure with a manometer. 2.Check manifold pressure gauge (manometer) connected to the manifold pressure tap on the gas control valve,

If full rate adjustment is required, remove cover screw from top of the gas control valve. Using a small screwdriver, turn adjusting screw clockwise to increase or counterclockwise to decrease gas pressure to obtain 4.0" W.C.(1 K pa) for natural gas and 10.0" W.C. (2.5 kPa) for L.P. Gas.

3.Cycle the burner on and off several times to check its operation.

4.Check the operation of the limit and operating controls.

5.Check the vent system seams and joints and ensure that there is no discharge of flue products into the room.

6.Check the input rate.

HIGH ALTITUDE INSTALLATIONS SUF 120 - 150

For appliance installation locations with elevations above 6,500 feet (1982 meters) consult the “High Altitude Installation” section of the owners manual.

a. Attach a pressure gauge (manometer) to the manifold pressure tap and refer to page 4 for correct pressure.

b. Use this formula to “clock” the meter. Be sure other gas consuming appliances are not operating during this interval.

Btuh = 3600 X H/ T

T = Time in seconds to burn 1 cubic foot of gas. (With a stopwatch read the gas meter and measure the amount of time required for the heater to consume 1 cubic foot of gas.)

H = Heating value of gas (in Btu’s per cubic foot of gas).

Btuh = Actual heater input rate, in Btuh. EXAMPLE: (Using

T = 25.25 seconds H = 1050 Btu/ft.3 BTUH = ?

Compare result to the

Should it be necessary to adjust the gas pressure to the burner, to obtain the full input rate, the steps below should be followed:

c. Remove the pressure regulator cover screw and adjust the pressure by turning the adjusting screw with a small screwdriver. Do not exceed 4.0" (1 kPa) natural gas models and 10.0" w.c. (2.5kPa) on the propane models. Clockwise to increase gas pressure and input rate. Counterclockwise to decrease gas pressure and input rate.

d. “Clock” the meter as in step (b) above.

e. Repeat steps (c) and (d) until the specified input rate is achieved.

f. Turn the manual gas valve to “OFF”. Replace the pressure regulator cover screw. Remove the pressure gauge or manometer from the manifold pressure tap. Replace the set screw in the manifold pressure tap. If the gas pressure regulator cannot be adjusted to give the full input rating with sufficient gas pressure at the valve, check to ensure the unit is equipped with the correct orifice.

State Water Heaters – Technical Training Department 5 | Ashland City, Tennessee © 2009 |

Servicing should only be performed by a Qualified Service Agent |