3-3 Compressed Air Blowback Connection

To provide proper filter element cleaning, the compressed air supply must be regulated to 80 PSI (5.5 bars). Low air pressure will cause poor filter element cleaning. Air consumption depends on the frequency and length of cleaning air pulses into the filter element.

Connect a minimum of 3/8” (9 mm) air line to the top of the solenoid valve air block. Compressed air must be clean, dry, and free of oil. A filter regulator and

You may need to install an accumulator in your air supply system to enhance blowback effectiveness if your system cannot consistently meet these requirements. Make sure you use

3-4 Implosion Blowback Connection

The clearing valve (implosion blowback valve) is located on the outlet of the vacuum filter. Connect the clearing valve to a

Run a 3/8” (9 mm) branch line to supply the vacuum hoppers in your system. Install a 3/8” (9 mm) x 1/8” (3 mm) tee valve in the up position near the filter chamber.

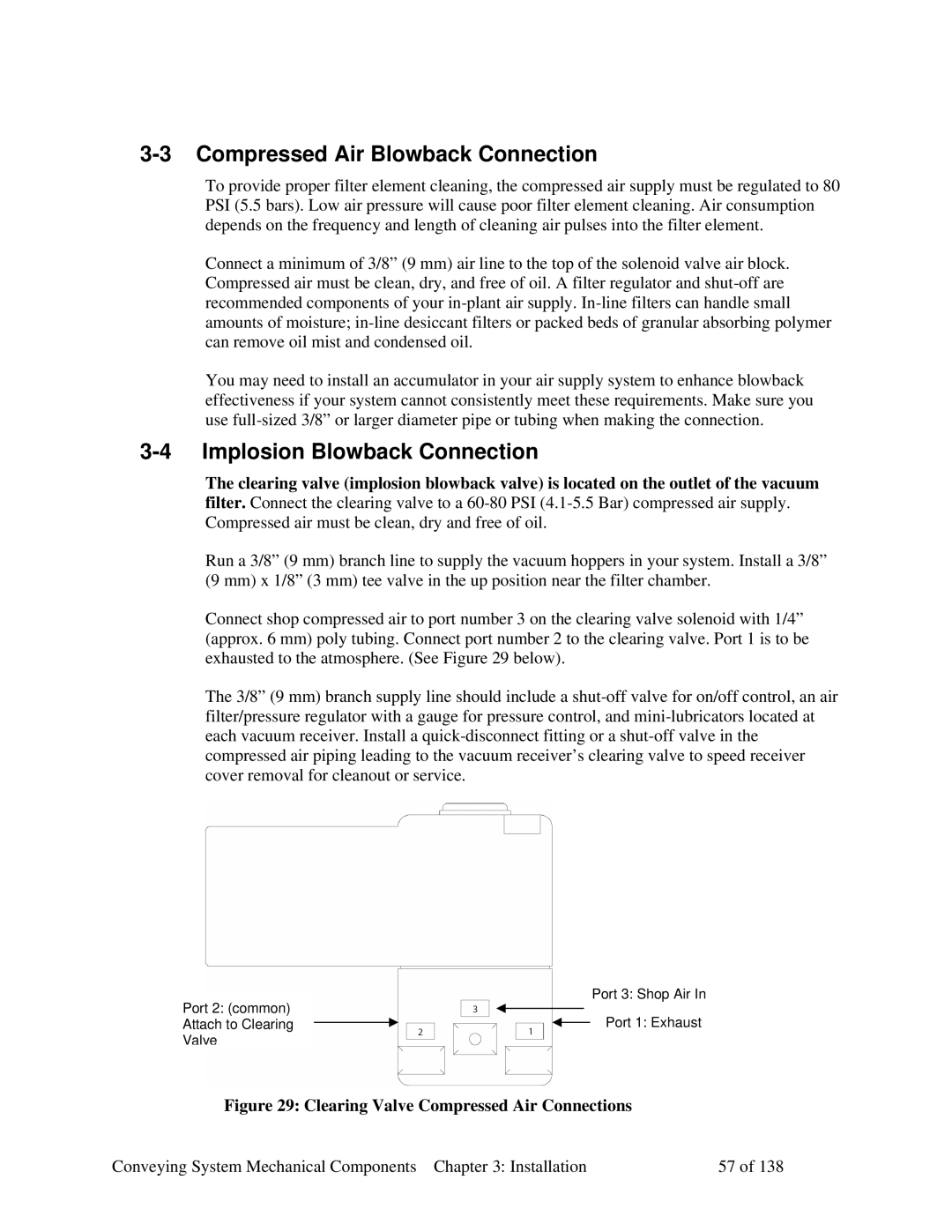

Connect shop compressed air to port number 3 on the clearing valve solenoid with 1/4” (approx. 6 mm) poly tubing. Connect port number 2 to the clearing valve. Port 1 is to be exhausted to the atmosphere. (See Figure 29 below).

The 3/8” (9 mm) branch supply line should include a

| Port 3: Shop Air In | |

Port 2: (common) | ||

Port 1: Exhaust | ||

Attach to Clearing | ||

Valve |

| |

|

|

Figure 29: Clearing Valve Compressed Air Connections

Conveying System Mechanical Components Chapter 3: Installation | 57 of 138 |