Part Number Bulletin Number SM2-605A.1 Effective 7/25/06

Conveying System Mechanical Components

Write Down Your Serial Numbers Here For Future Reference

Event of Shipping Damage

Unpacking and Inspection

If the Shipment is Not Complete

If the Shipment is Not Correct

Credit Returns

Warranty Returns

Table of Contents

Operation

Troubleshooting

Charts and Figures

106

105

108

109

Safety Symbols Used in this Manual

How to Use This Manual

Wear Safety Glasses and Work Gloves

Conveying System Safety Tags Description

Operate this equipment within design specifications

General Responsibility

Responsibility

Remember

Operator Responsibility

Reporting a Safety Defect

Maintenance Responsibility

General Description

Models Covered in This Manual

Basic System Components

Basic System Types

Volume-Fill Systems

Time-Fill Systems

Conveying Distance

SSI Series Inventory Vacuum Receivers

Standard Features & Options

Models SSI03, SSI06, SSI11

SSI03 Vacuum Receiver

SPD Series Models SPD5, SPD7.5, SPD10, SPD15

Pumps

Options

Positive Displacement Pump Dimensions

SPD Series Models SPD20, SPD30

SPD 20, 30 Series Pump Dimensions

Spdb Series Models SPDB5, SPDB7.5, SPDB10, SPDB15

Blowback Pumps

Spdb 5-15 Series Blowback Pump Dimensions

Spdb Series Models Spdb 25, Spdb

Spdb 25, 30 Series Blowback Pump Dimensions

Models 3.5, 6.5 & 11 Hp

SPC Centrifugal Pumps

At 460/3/60

13.4 120 385 Spdb 20.6 10.3 155 400

Options

SSR Series Stainless Steel Vacuum Receiver Dimensions

Metric Standards ∙ Dimensions in cm

SSR 6-45 Stainless Steel Vacuum Receiver Dimensions

SSR 85/170 Stainless Steel Vacuum Receiver Dimensions

Models AV1.5, AV2, AV2.25, AV2.5, AV3

Atmospheric Valves

Models SV1.5, SV2, SV2.25, SV2.5, SV3, SV4, SV4.5, SV5

Sequence T-Valves

Models SFC225, SFC1000

Cartridge-Style Vortex Filter Chamber

SFC Vortex Filter Chamber Specifications and Dimensions

Models FC15, FC30, FC55

FC Series Bag-Style Filters

∙ Filter media available ∙ Enclosed floor stand

ACA Series Filter Chambers

Typical ACA Series Filter Chamber

Filter Tank, Overall Dimensions

SFC-S Series Filters

Specifications and Dimensions

Model SFC-S Filter

Take-Off Compartment Models

Take-Off Compartments and Pickup Tubes

Typical Take-Off Compartment

FCO-1.5MD

Safety Circuit Standards

Safety Devices and Interlocks

Fail Safe Operation

Safety Device Lock-Outs

Uncrating the Equipment

Installing the Pump Package

Rigging and Placing Mechanical Components

Vacuum Pump Vent Piping Considerations

Conveying System Mechanical Components Installation

Blowback solenoid To vacuum Line

Installing Material/Vacuum Tubing

Installing the Control Panel

Multiple Line System Piping Considerations

Typical Multiple Line System Installation

Single Line Y-Tube System Considerations

Recommended Single-Line Y-Tube Installation

Modified Single-Line Y-Tube Installation

Page

Typical Material Check Valve

Installing SFC or FC Filter Chambers

Installing ACA Series Filter Chambers

Installing the Filter Chamber Shroud

Installing the Safety Filter

Installing Vacuum Receivers and Inventory/Vacuum Receivers

SFC-S Filter Installation

Implosion Blowback Connection

Compressed Air Blowback Connection

Flange Mount Vacuum Receiver Mounting

Positioning and Spacing on the Demand Switch

Orienting the Unit

Installing the Pickup Probe

Installing and Adjusting the Take-off Compartment

Installing the Grinder Take-off Attachment

Adjusting Fast Take-off FCO Compartments

Typical Powder Check Adapter

Making ACA Series Filter Chamber Compressed Air Connections

Compressed Air Connections

Making Pump Compressed Air Connections

Solenoid Valve

Solenoid Valve

Making Control Panel Power Drop Wiring Connections

Making Pump Power Drop Wiring Connections

Electrical Connections

Making ACA Series Filter Chamber Electrical Connections

Connecting the Control Panel to Vacuum Receivers

Vacuum Receiver Volume fill

Vacuum Receiver Volume Fill Vacuum Receiver Time Fill

Installing Station Bypass Switches

Connecting the Control Panel to the Pump Package

Recommended Field-Installed Optional Station Bypass Switch

Typical SPD Series Junction Box Wiring Diagram

SUB Panel Layout and Connection Diagram

Typical Spdb 5-15 Series Junction Box Wiring Diagram

Typical Spdb 25, 30 Series Junction Box Wiring Diagram

Junction BOX on Vacuum Pump

Initial Start-up

Adjusting Sight Glass Proximity Sensor Sensitivity

Making Startup Checks

ACA Series Filter Chamber Pre-Operation Checklist

Adjusting Air Pulse Duration All Models

Adjusting Time Between Air Pulses on ACA Filters

Adjusting the Number of Air Pulses

Models Equipped with Volume-Fill Switch Only

Adjusting Proximity Sensor Sensitivity

Starting ACA Series Filter Chamber Units

Vacuum Switch VS Operation

Operation Procedures

Start-up

High Vacuum Relief Regulator Operation

Shut-down

Photocopy this page for your maintenance records

Preventative Maintenance Schedule

Conveying System Mechanical Components Maintenance

Maintaining Pump Packages

Preventative Maintenance

Oil Capacities-SPD Only

Suggested Lubricants

SFC Filter Chambers

Maintaining Filter Chambers

Inspecting ACA Series Filter Chamber Filter Bags

See Valve Assembly Drawings and Spare Parts Lists in Figures

Maintaining Lower Valves 5 to 15 HP 3.73-11.19 kW Spdb Units

Disassembling Lower Valves

Removing Upper Valves

Reinstalling Upper Valves

Servicing and Reassembling Lower Valves

Reinstalling Lower Valves

Cleaning the Filter Shroud SFC 225 and SFC 1000 Only

SFC-S

Cleaning/Replacing the Filter Cartridge

Dealing with Shortened ACA Series Filter Bag Life

Corrective Maintenance

Reset the overload and check

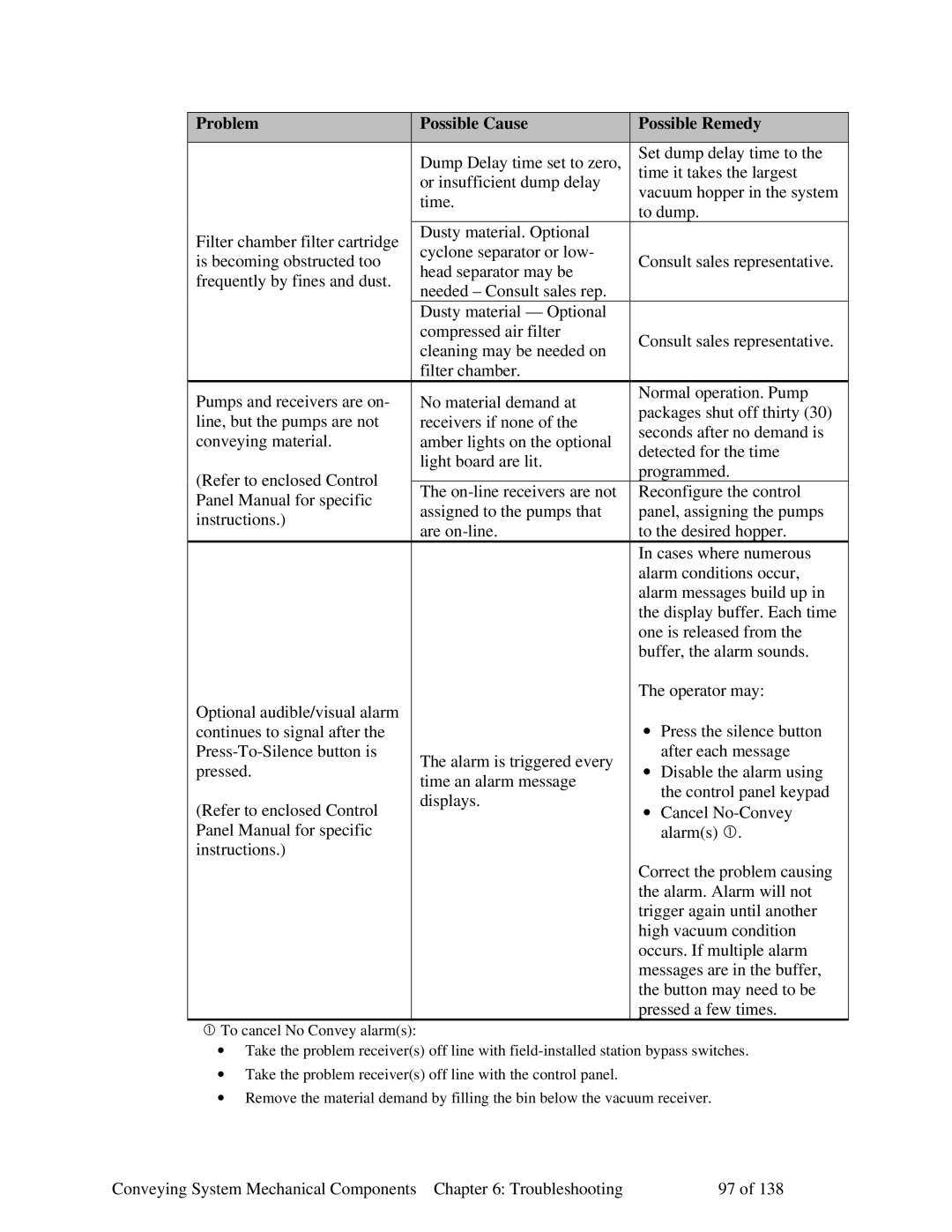

Problem Possible Cause Possible Remedy

Introduction

Problem Possible Cause Possible Remedy

If needed see

Find and remove

Problem Possible Cause Possible Remedy

Failure Repair/replace problem

Alarm package component Troubleshoot

Proper signal, voltage,

Blower is dead-headed

Operation clean or repair

Dirty filter. Clean or replace

Check for faulty

Voltage signal during

Clean fouled flapper

Replace or re-install worn

Check counterweight

Repair or adjust as

Immediately

Filters in the filter chamber Replace or repair

Warranty Specifications

Warranty

Warranty Restrictions

Customer Responsibilities

Warranty Liabilities

Technical Specifications

Conveying System Mechanical Components Appendix 105

Drawings and Diagrams

Conveying System Mechanical Components Appendix 106

Equipment Cycles

Conveying System Mechanical Components Appendix 107

Conveying System Mechanical Components Appendix 108

Spare Parts List

Conveying System Mechanical Components Appendix 109

See for parts location

Conveying System Mechanical Components Appendix 110

Conveying System Mechanical Components Appendix 111

SSR Series Vacuum Receiver Parts List Pre-May

Conveying System Mechanical Components Appendix 112

Conveying System Mechanical Components Appendix 113

See on the previous page for parts location

Conveying System Mechanical Components Appendix 114

Conveying System Mechanical Components Appendix 115

SSR85/170 Series Vacuum Receiver Parts List

Conveying System Mechanical Components Appendix 116

Typical SSI Series Inventory Vacuum Receiver Exploded View

Conveying System Mechanical Components Appendix 117

SSI Series Inventory Vacuum Receiver Parts List

FC Filter Chamber Spare Parts List, Models FC15, FC30, FC35

SFC Filter Chamber Spare Parts List, Models SFC225, SFC1000

Conveying System Mechanical Components Appendix 119

Conveying System Mechanical Components Appendix 120

Conveying System Mechanical Components Appendix 121

Conveying System Mechanical Components Appendix 122

Conveying System Mechanical Components Appendix 123

SFC-S Filter

Conveying System Mechanical Components Appendix 124

SFC-S Filter Spare Parts List

Conveying System Mechanical Components Appendix 125

SPD Spare Parts Drawing

Conveying System Mechanical Components Appendix 126

SPD Spare Parts List

Conveying System Mechanical Components Appendix 127

SPD Spare Parts List Cont’d

Elbow Fitting

Conveying System Mechanical Components Appendix 128

Conveying System Mechanical Components Appendix 129

Reversing Valve Assembly Spare Parts Drawing

Conveying System Mechanical Components Appendix 130

SPD Reversing Valve Option Spare Parts List

Conveying System Mechanical Components Appendix 131

Spdb Spare Parts Drawing

REG. AIR Mint 127111000 HPR LDR

Conveying System Mechanical Components Appendix 132

Conveying System Mechanical Components Appendix 133

Spdb Spare Parts List Cont’d

Conveying System Mechanical Components Appendix 134

Conveying System Mechanical Components Appendix 135

SPC Spare Parts Drawing

Centrifugal Vacuum Pump Spare Parts List

Conveying System Mechanical Components Appendix 137

Technical Assistance

Service Department

Parts Department

Sales Department