STUDER Innotec | |

|

|

4.6.3Overheating (Over Temp)

If the Inverter has been overloaded for a long time or it has been working in a too high surrounding temperatures, it will switch off. The LED 13 „OFF“ blinks. After cooling down, the inverter switches back on automatically. One minute before the inverter switches off for too high temperature it gives out an acoustic alarm signal. The Auxiliary Contact programmed in factory to detect the high tem- perature synchronizes the relay with the alarm signal. In this way, for example, an emergency back up system can be started without any break in the energy supply.

4.6.4Battery Condition

Deep discharging of the

The low voltage is set to 11.8V / 23.6V / 47.2V. These settings are standard for most batteries. These voltage levels are maintained by the

This setting is comparable with the levels of 10.8V/ 21.6V / 43.2, which are given for most batteries on nominal load.

All voltage levels (equalization absorption floating and disconnection voltage), can be programmed by mean of the optional remote control.

4.7The Battery charger

4.7.1Cycle of charge

The full automatic

During the charging phase the consuming appliances at the outlet AC OUT are continuously sup- plied with power (LED 8 AC OUT is lit).

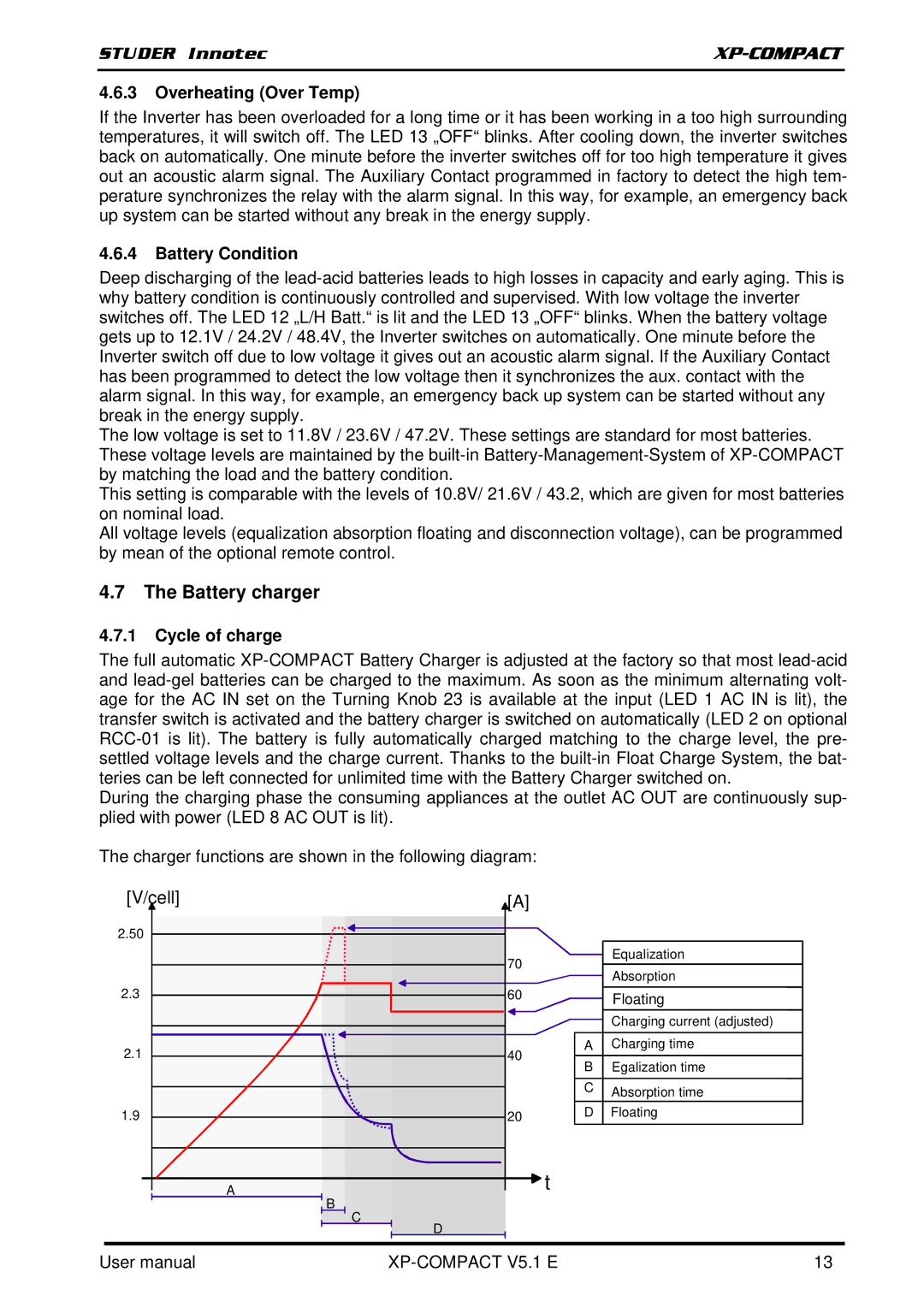

The charger functions are shown in the following diagram:

[V/cell] | [A] |

|

| |

2.50 |

|

|

| |

| 70 |

| Equalization | |

|

|

| ||

2.3 |

| Absorption | ||

|

| |||

60 |

|

| ||

| Floating | |||

|

|

| ||

|

|

| Charging current (adjusted) | |

|

|

| Charging time | |

2.1 | 40 | A | ||

B | Egalization time | |||

|

| |||

|

| C | Absorption time | |

|

|

| ||

1.9 | 20 | D | Floating |

| A | t |

|

|

| B |

|

|

| C |

|

|

| D |

|

User manual |

| 13 | |