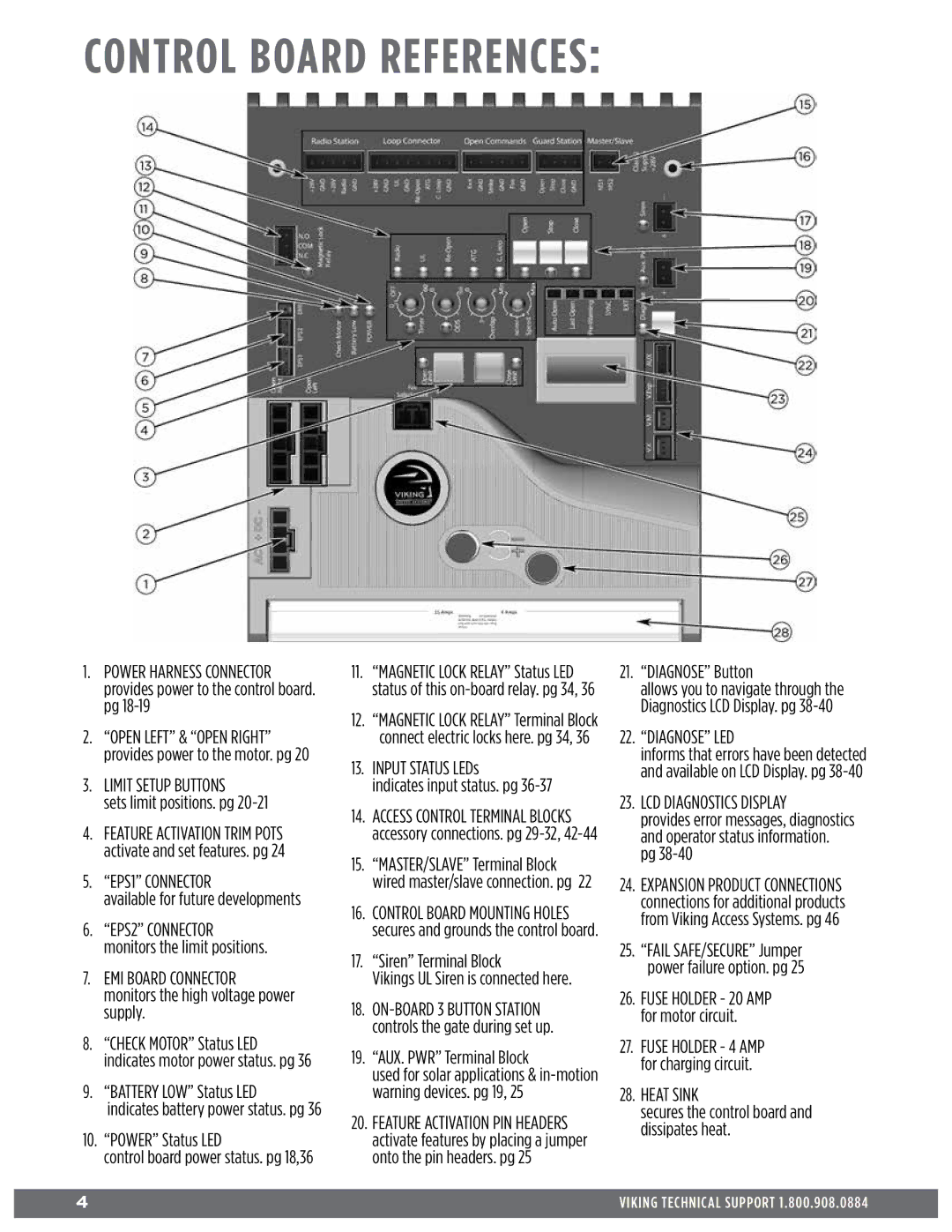

CONTROL BOARD REFERENCES:

1.POWER HARNESS CONNECTOR provides power to the control board. pg

2.“OPEN LEFT” & “OPEN RIGHT” provides power to the motor. pg 20

3.LIMIT SETUP BUTTONS

sets limit positions. pg

4.FEATURE ACTIVATION TRIM POTS activate and set features. pg 24

5.“EPS1” CONNECTOR

available for future developments

6.“EPS2” CONNECTOR monitors the limit positions.

7.EMI BOARD CONNECTOR

monitors the high voltage power supply.

8.“CHECK MOTOR” Status LED indicates motor power status. pg 36

9.“BATTERY LOW” Status LED

indicates battery power status. pg 36

10.“POWER” Status LED

control board power status. pg 18,36

11.“MAGNETIC LOCK RELAY” Status LED status of this

12.“MAGNETIC LOCK RELAY” Terminal Block connect electric locks here. pg 34, 36

13.INPUT STATUS LEDs

indicates input status. pg 36-37

14.ACCESS CONTROL TERMINAL BLOCKS accessory connections. pg

15.“MASTER/SLAVE” Terminal Block wired master/slave connection. pg 22

16.CONTROL BOARD MOUNTING HOLES secures and grounds the control board.

17.“Siren” Terminal Block

Vikings UL Siren is connected here.

18.

19.“AUX. PWR” Terminal Block

used for solar applications &

20.FEATURE ACTIVATION PIN HEADERS activate features by placing a jumper onto the pin headers. pg 25

21.“DIAGNOSE” Button

allows you to navigate through the Diagnostics LCD Display. pg

22.“DIAGNOSE” LED

informs that errors have been detected and available on LCD Display. pg

23.LCD DIAGNOSTICS DISPLAY

provides error messages, diagnostics and operator status information. pg

24.EXPANSION PRODUCT CONNECTIONS connections for additional products from Viking Access Systems. pg 46

25.“FAIL SAFE/SECURE” Jumper

power failure option. pg 25

26.FUSE HOLDER - 20 AMP for motor circuit.

27.FUSE HOLDER - 4 AMP for charging circuit.

28.HEAT SINK

secures the control board and dissipates heat.

4 | VIKING TECHNICAL SUPPORT 1.800.908.0884 |

|

|