DIRECT IGNITION PROPANE/LP GAS CONVERSION

1.Turn off the gas supply.

2.Turn off the electrical supply to the appliance if so equipped.

3.Open or remove glass doors if applicable.

4.Remove top louver and lower bottom louver.

5.Remove logs from burner assembly.

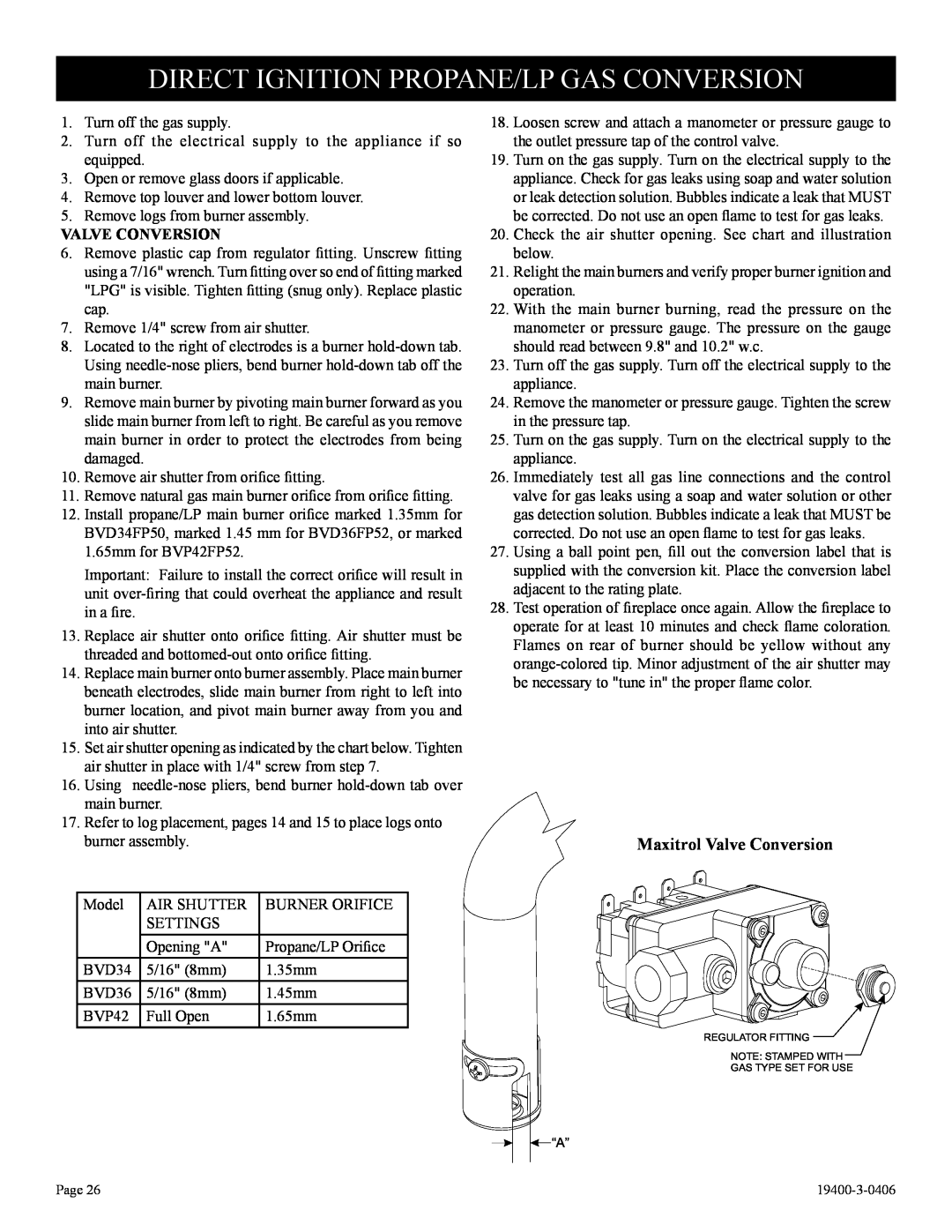

VALVE CONVERSION

6.Remove plastic cap from regulator fitting. Unscrew fitting using a 7/16" wrench. Turn fitting over so end of fitting marked "LPG" is visible. Tighten fitting (snug only). Replace plastic cap.

7.Remove 1/4" screw from air shutter.

8.Located to the right of electrodes is a burner

9.Remove main burner by pivoting main burner forward as you slide main burner from left to right. Be careful as you remove main burner in order to protect the electrodes from being damaged.

10.Remove air shutter from orifice fitting.

11.Remove natural gas main burner orifice from orifice fitting.

12.Install propane/LP main burner orifice marked 1.35mm for BVD34FP50, marked 1.45 mm for BVD36FP52, or marked 1.65mm for BVP42FP52.

Important: Failure to install the correct orifice will result in unit

13.Replace air shutter onto orifice fitting. Air shutter must be threaded and

14.Replace main burner onto burner assembly. Place main burner beneath electrodes, slide main burner from right to left into burner location, and pivot main burner away from you and into air shutter.

15.Set air shutter opening as indicated by the chart below. Tighten air shutter in place with 1/4" screw from step 7.

16.Using

17.Refer to log placement, pages 14 and 15 to place logs onto burner assembly.

Model | AIR SHUTTER | BURNER ORIFICE |

| SETTINGS |

|

| Opening "A" | Propane/LP Orifice |

BVD34 | 5/16" (8mm) | 1.35mm |

BVD36 | 5/16" (8mm) | 1.45mm |

BVP42 | Full Open | 1.65mm |

18.Loosen screw and attach a manometer or pressure gauge to the outlet pressure tap of the control valve.

19.Turn on the gas supply. Turn on the electrical supply to the appliance. Check for gas leaks using soap and water solution or leak detection solution. Bubbles indicate a leak that MUST be corrected. Do not use an open flame to test for gas leaks.

20.Check the air shutter opening. See chart and illustration below.

21.Relight the main burners and verify proper burner ignition and operation.

22.With the main burner burning, read the pressure on the manometer or pressure gauge. The pressure on the gauge should read between 9.8" and 10.2" w.c.

23.Turn off the gas supply. Turn off the electrical supply to the appliance.

24.Remove the manometer or pressure gauge. Tighten the screw in the pressure tap.

25.Turn on the gas supply. Turn on the electrical supply to the appliance.

26.Immediately test all gas line connections and the control valve for gas leaks using a soap and water solution or other gas detection solution. Bubbles indicate a leak that MUST be corrected. Do not use an open flame to test for gas leaks.

27.Using a ball point pen, fill out the conversion label that is supplied with the conversion kit. Place the conversion label adjacent to the rating plate.

28.Test operation of fireplace once again. Allow the fireplace to operate for at least 10 minutes and check flame coloration. Flames on rear of burner should be yellow without any

Maxitrol Valve Conversion

REGULATOR FITTING ![]()

NOTE: STAMPED WITH

GAS TYPE SET FOR USE

“A”

Page 26 |