Disassembly Procedures

!WARNING

To avoid risk of electrical shock, personal injury or death, disconnect power to unit before servicing.

Tub Seal Replacement

1.Disconnect power supply to unit.

2.Remove Tub Seal, see “Tub Seal/Transmission Disassembly” procedure.

3.Make sure both mating surfaces on Transmission shaft are free of foreign matter, then clean both surfaces with an alcohol saturated cloth.

4.Apply a thin layer of grease to the locations indicated in the following images to Seal Nut and Triple Lip Seal before installing. Insure that no grease gets on Snubber, Stater, or Brake Lining.

NOTE: Do not use any agent other than alcohol to clean the mating surface. Do not use any lubricant other than

Silicone Grease, part number 203959.

Apply grease to location indicated with arrow on Triple Lip Seal.

Apply grease to locations indicated with arrows on Seal Nut.

Spin Bearing Replacement

1.Disconnect power supply to unit.

2.Press the Spin Bearing out of the cavity from the opposite side of the housing.

3.When installing the replacement bearing into the housing cavity, be sure to press against the outer race of the bearing to avoid damage to the bearing shield and causing premature failure.

Oil Seal Replacement

The Oil Seal is located in the spline end of the drive tube. The Oil Seal can be replaced without removing or disassembling the Transmission.

1.Disconnect power supply to unit.

2.Tip Washer back to access bottom side and remove Drive Belt, Dust Cap, Retaining Ring, Washer, Cam, Drive Pulley, Thrust Bearing and Spacer, see “Drive Pully and Cam Removal” procedure.

3.Remove the Brake assembly to access the Oil Seal, see “Brake Disassembly” procedure.

4.Use a thin, flat bladed screwdriver to carefully pry the old Oil Seal out.

5.Place the drive washer (tool number 14242) and the new Oil Seal over the seal protector.

6.Remove the

7.Slide the Transmission seal driver (tool number 14242) over the drive shaft until it makes contact with the drive washer. Use the impact sleeve of the tool to "tap" the Oil Seal into the end of the drive tube.

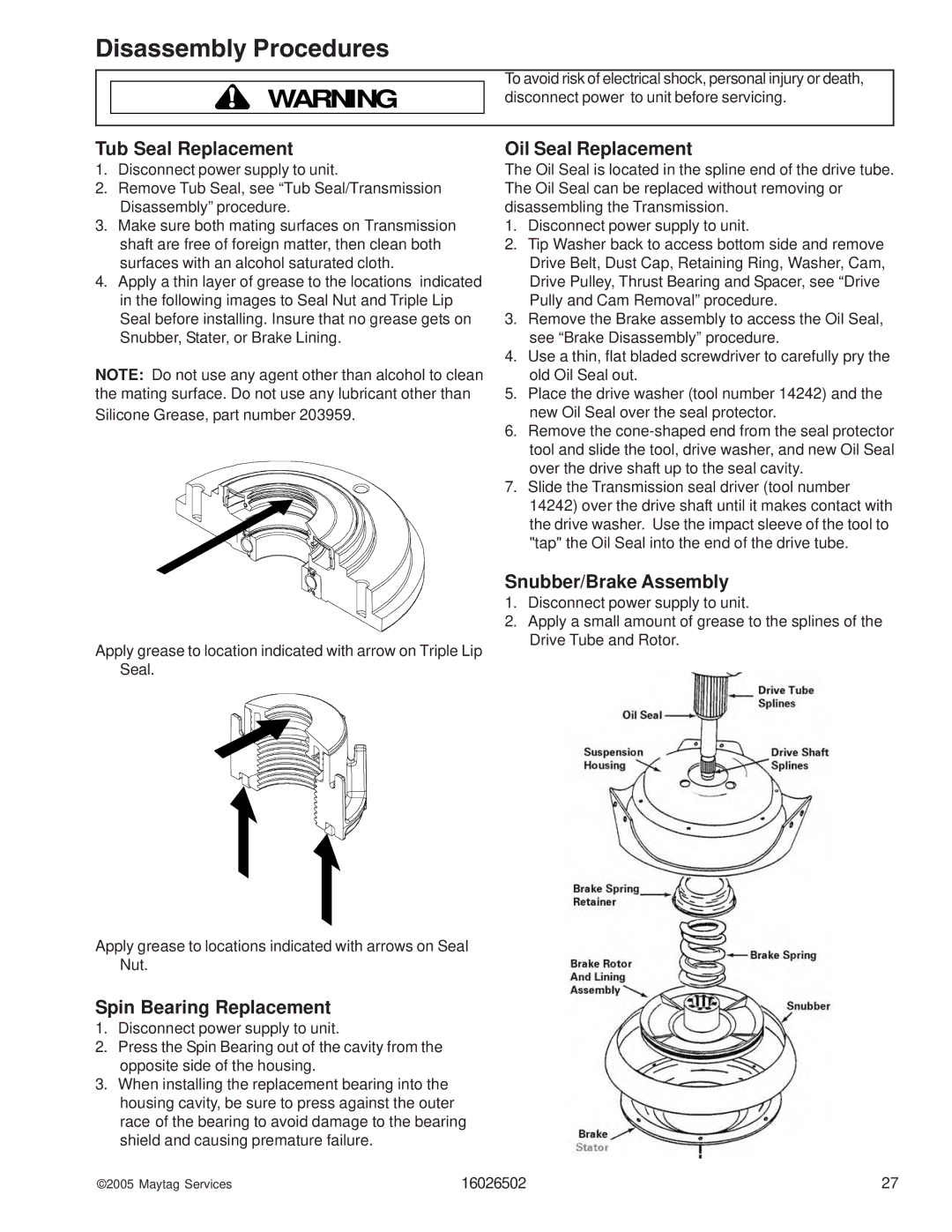

Snubber/Brake Assembly

1.Disconnect power supply to unit.

2.Apply a small amount of grease to the splines of the Drive Tube and Rotor.

©2005 Maytag Services | 16026502 | 27 |