Seasonal Lubrication

In addition to the daily recommended lubrication, a more extensive application is recommended season- ally.

1.Fill CV double yokes with 20 pumps of grease with the joints in a straight line.

2.Articulate CV body to maximum angle several times to ensure full coverage of joints.

3.Place joints in the straight position and add 10 additional pumps of grease to both joints.

4.Wipe telescoping drive clean of all old grease and contaminants.

5.Add a thin layer of new grease over telescoping drive.

BLADES

Before working underneath, read manual instructions, securely block up, and check stabil- ity. Secure blocking prevents equipment from dropping due to hydraulic leak down, hydraulic system failure, or mechanical component failure.

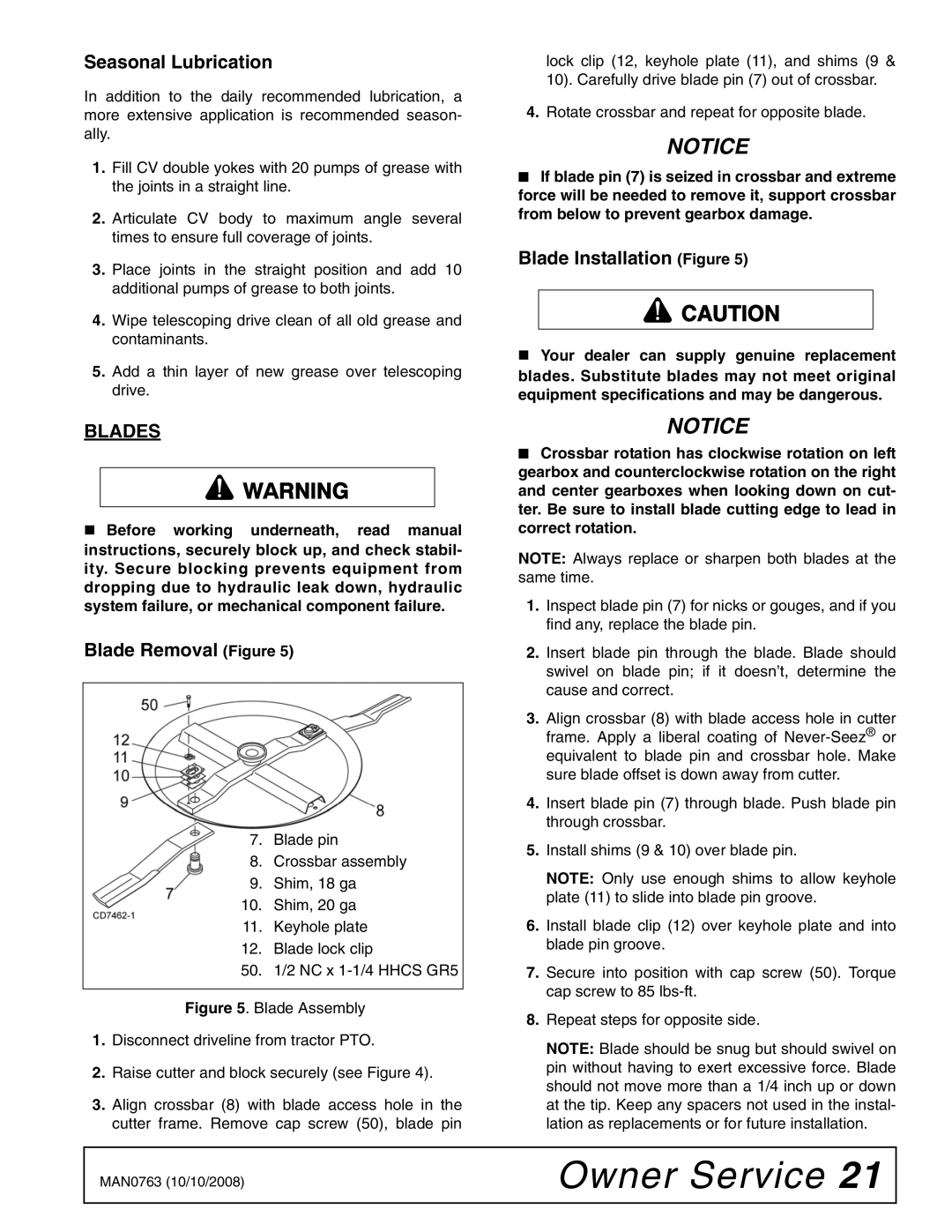

Blade Removal (Figure 5)

7.Blade pin

8.Crossbar assembly

9.Shim, 18 ga

10.Shim, 20 ga

11.Keyhole plate

12.Blade lock clip

50.1/2 NC x

Figure 5. Blade Assembly

1.Disconnect driveline from tractor PTO.

2.Raise cutter and block securely (see Figure 4).

3.Align crossbar (8) with blade access hole in the cutter frame. Remove cap screw (50), blade pin

lock clip (12, keyhole plate (11), and shims (9 & 10). Carefully drive blade pin (7) out of crossbar.

4.Rotate crossbar and repeat for opposite blade.

NOTICE

■If blade pin (7) is seized in crossbar and extreme force will be needed to remove it, support crossbar from below to prevent gearbox damage.

Blade Installation (Figure 5)

![]() CAUTION

CAUTION

Your dealer can supply genuine replacement blades. Substitute blades may not meet original equipment specifications and may be dangerous.

NOTICE

■Crossbar rotation has clockwise rotation on left gearbox and counterclockwise rotation on the right and center gearboxes when looking down on cut- ter. Be sure to install blade cutting edge to lead in correct rotation.

NOTE: Always replace or sharpen both blades at the same time.

1.Inspect blade pin (7) for nicks or gouges, and if you find any, replace the blade pin.

2.Insert blade pin through the blade. Blade should swivel on blade pin; if it doesn’t, determine the cause and correct.

3.Align crossbar (8) with blade access hole in cutter frame. Apply a liberal coating of

4.Insert blade pin (7) through blade. Push blade pin through crossbar.

5.Install shims (9 & 10) over blade pin.

NOTE: Only use enough shims to allow keyhole plate (11) to slide into blade pin groove.

6.Install blade clip (12) over keyhole plate and into blade pin groove.

7.Secure into position with cap screw (50). Torque cap screw to 85

8.Repeat steps for opposite side.

NOTE: Blade should be snug but should swivel on pin without having to exert excessive force. Blade should not move more than a 1/4 inch up or down at the tip. Keep any spacers not used in the instal- lation as replacements or for future installation.

MAN0763 (10/10/2008) | Owner Service 21 |

|

|