WOODS

MAINTENANCE

HYDRAULIC SYSTEM

Fluid level in the hydraulic system should be checked after the first 5 hours of operation, and every 100 hours thereafter, or when a leak has occurred. If the fluid is low, check all components for leaks.

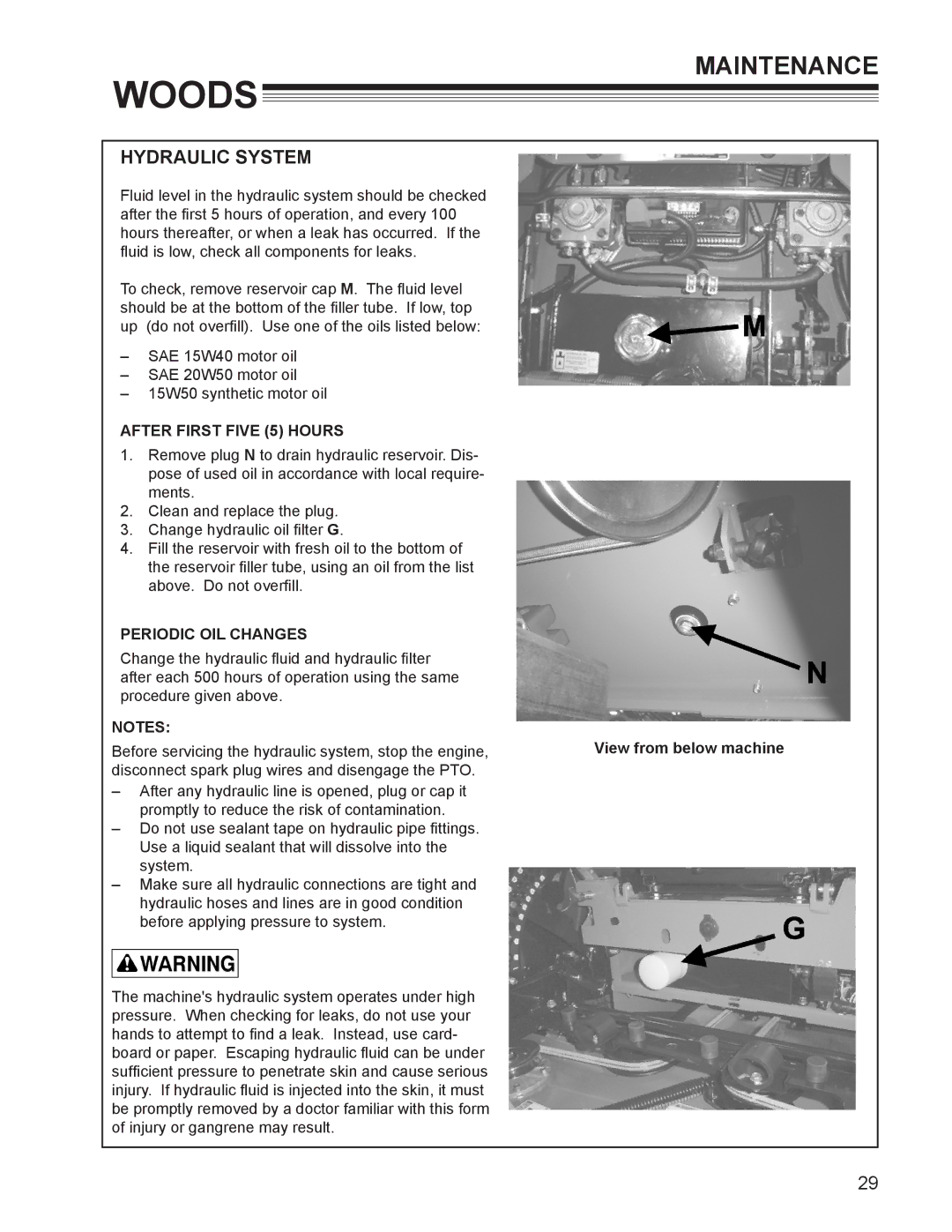

To check, remove reservoir cap M. The fluid level should be at the bottom of the filler tube. If low, top up (do not overfill). Use one of the oils listed below:

– SAE 15W40 motor oil

– SAE 20W50 motor oil

– 15W50 synthetic motor oil

AFTER FIRST FIVE (5) HOURS

1. Remove plug N to drain hydraulic reservoir. Dis- pose of used oil in accordance with local require- ments.

2. Clean and replace the plug.

3. Change hydraulic oil filter G.

4. Fill the reservoir with fresh oil to the bottom of

the reservoir filler tube, using an oil from the list above. Do not overfill.

PERIODIC OIL CHANGES

Change the hydraulic fluid and hydraulic filter after each 500 hours of operation using the same procedure given above.

NOTES: | View from below machine |

Before servicing the hydraulic system, stop the engine, | |

disconnect spark plug wires and disengage the PTO. |

|

– After any hydraulic line is opened, plug or cap it |

|

promptly to reduce the risk of contamination. |

|

– Do not use sealant tape on hydraulic pipe fittings. |

|

Use a liquid sealant that will dissolve into the |

|

system. |

|

– Make sure all hydraulic connections are tight and |

|

hydraulic hoses and lines are in good condition |

|

before applying pressure to system. |

|

The machine's hydraulic system operates under high |

|

pressure. When checking for leaks, do not use your |

|

hands to attempt to find a leak. Instead, use card- |

|

board or paper. Escaping hydraulic fluid can be under |

|

sufficient pressure to penetrate skin and cause serious |

|

injury. If hydraulic fluid is injected into the skin, it must |

|

be promptly removed by a doctor familiar with this form |

|

of injury or gangrene may result. |

|

29