M1109 Combo Lathe/Mill

Setting Power Feed Rate

The carriage has longitudinal and cross slide power feed capabilities. All directions reverse when spindle rotation is reversed.

NOTICE

Feed rate is based on spindle RPM. High feed rates combined with high spindle speeds result in a rapidly moving carriage or cross slide. Pay close attention to the feed rate you have chosen and be ready to disengage the apron. Failure to do this may cause the carriage to crash into the chuck.

To set and engage the power feed, do these steps:

1. | DISCONNECT THE LATHE/MILL FROM POWER! |

2. | Refer to the Change Gear Chart on Page 29, or |

| the chart on the inside of the change gear door to |

| determine the needed combination of gears and |

| which spindle location to install each gear on. |

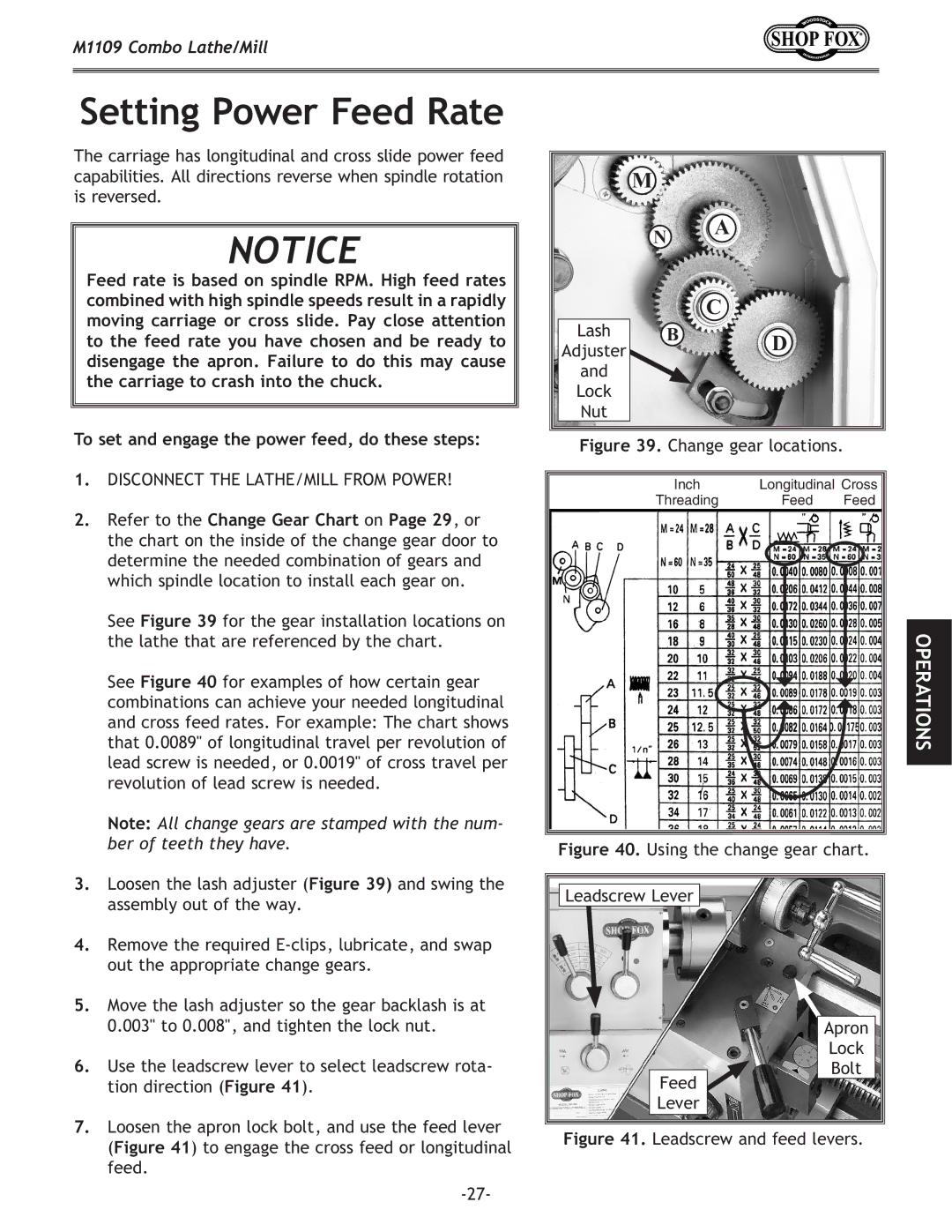

| See Figure 39 for the gear installation locations on |

| the lathe that are referenced by the chart. |

| See Figure 40 for examples of how certain gear |

| combinations can achieve your needed longitudinal |

| and cross feed rates. For example: The chart shows |

| that 0.0089" of longitudinal travel per revolution of |

| lead screw is needed, or 0.0019" of cross travel per |

| revolution of lead screw is needed. |

| Note: All change gears are stamped with the num- |

| ber of teeth they have. |

3. | Loosen the lash adjuster (Figure 39) and swing the |

| assembly out of the way. |

4. | Remove the required |

| out the appropriate change gears. |

5. | Move the lash adjuster so the gear backlash is at |

| 0.003" to 0.008", and tighten the lock nut. |

M

NA

C

Lash | B | D |

|

Adjuster |

|

| |

|

|

| |

and |

|

|

|

Lock |

|

|

|

Nut |

|

|

|

Figure 39. Change gear locations. | |||

| Inch | Longitudinal Cross | |

| Threading | Feed | Feed |

Figure 40. Using the change gear chart.

Leadscrew Lever

Apron

Lock

OPERATIONS

6. Use the leadscrew lever to select leadscrew rota- |

tion direction (Figure 41). |

Feed

Bolt

7. Loosen the apron lock bolt, and use the feed lever |

(Figure 41) to engage the cross feed or longitudinal |

feed. |

Lever