M1109 Combo Lathe/Mill

Headstock Positioning

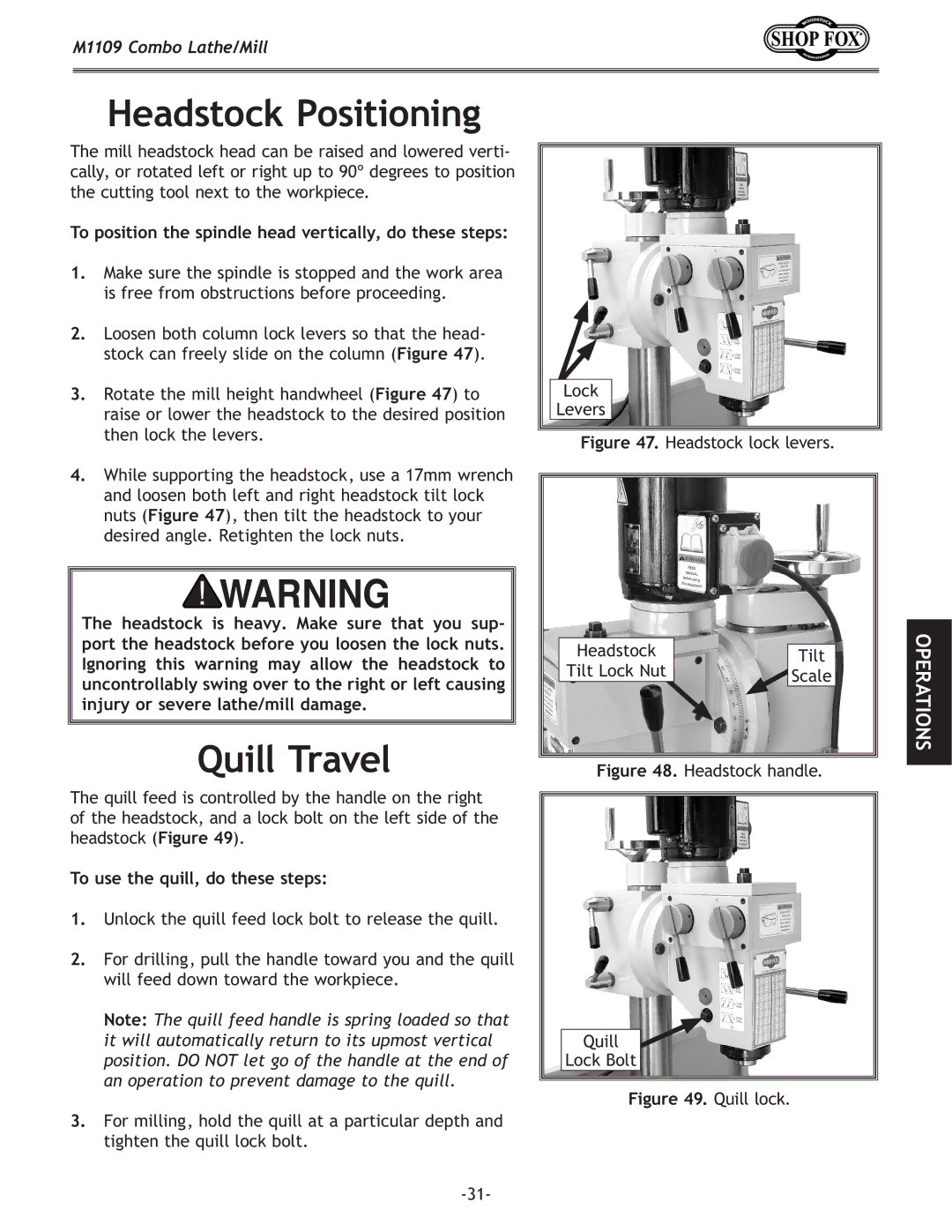

The mill headstock head can be raised and lowered verti- cally, or rotated left or right up to 90º degrees to position the cutting tool next to the workpiece.

To position the spindle head vertically, do these steps:

1.Make sure the spindle is stopped and the work area is free from obstructions before proceeding.

2.Loosen both column lock levers so that the head- stock can freely slide on the column (Figure 47).

3.Rotate the mill height handwheel (Figure 47) to raise or lower the headstock to the desired position then lock the levers.

4.While supporting the headstock, use a 17mm wrench and loosen both left and right headstock tilt lock nuts (Figure 47), then tilt the headstock to your desired angle. Retighten the lock nuts.

The headstock is heavy. Make sure that you sup- port the headstock before you loosen the lock nuts. Ignoring this warning may allow the headstock to uncontrollably swing over to the right or left causing injury or severe lathe/mill damage.

Quill Travel

The quill feed is controlled by the handle on the right of the headstock, and a lock bolt on the left side of the headstock (Figure 49).

To use the quill, do these steps:

1.Unlock the quill feed lock bolt to release the quill.

2.For drilling, pull the handle toward you and the quill will feed down toward the workpiece.

Note: The quill feed handle is spring loaded so that it will automatically return to its upmost vertical position. DO NOT let go of the handle at the end of an operation to prevent damage to the quill.

3.For milling, hold the quill at a particular depth and tighten the quill lock bolt.

Lock

Levers

Figure 47. Headstock lock levers.

Headstock | Tilt | |

Tilt Lock Nut | ||

Scale | ||

|

Figure 48. Headstock handle.

Quill

Lock Bolt

Figure 49. Quill lock.

OPERATIONS