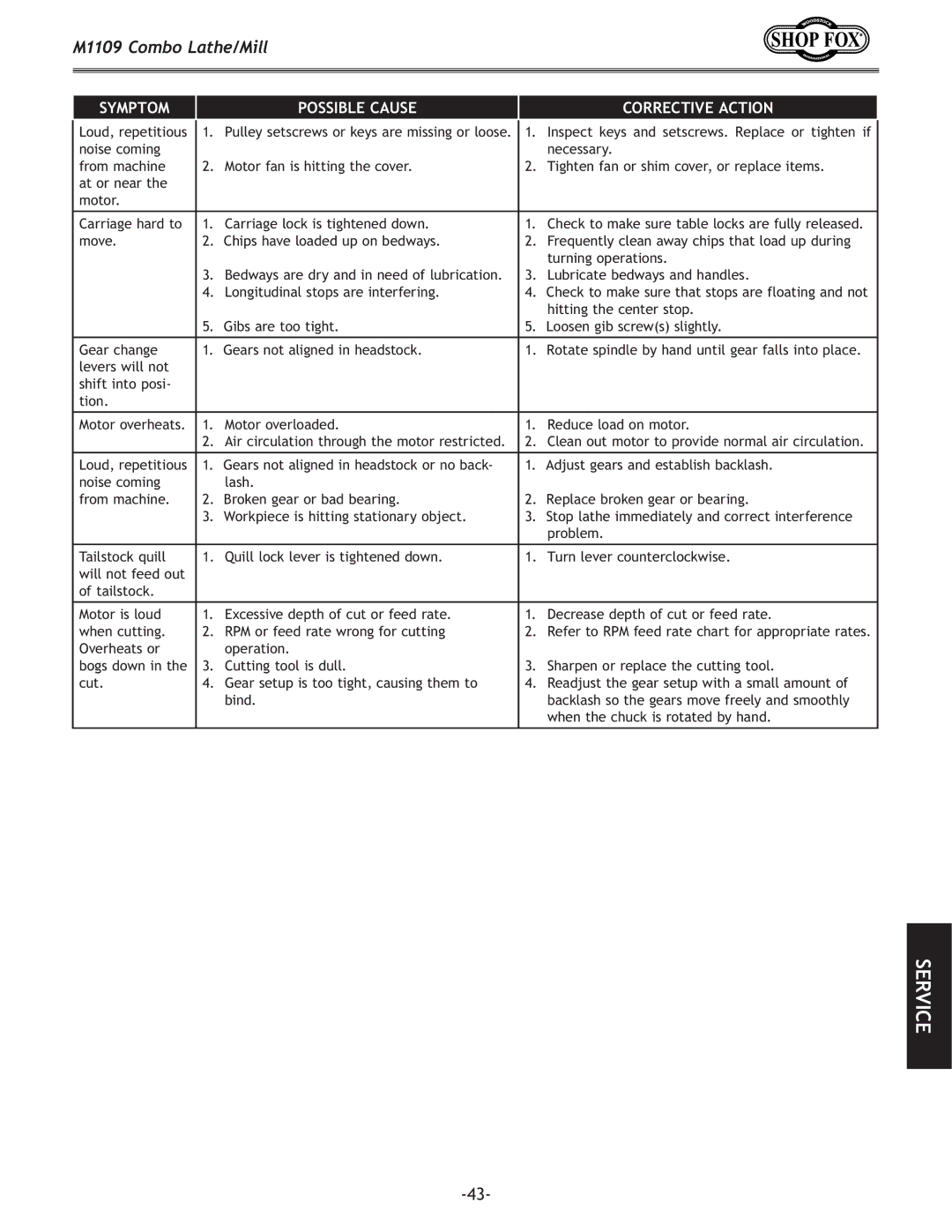

M1109 Combo Lathe/Mill

SYMPTOM

POSSIBLE CAUSE

CORRECTIVE ACTION

Loud, repetitious | 1. | Pulley setscrews or keys are missing or loose. | 1. | Inspect keys and setscrews. Replace or tighten if |

noise coming |

|

|

| necessary. |

from machine | 2. | Motor fan is hitting the cover. | 2. | Tighten fan or shim cover, or replace items. |

at or near the |

|

|

|

|

motor. |

|

|

|

|

Carriage hard to | 1. | Carriage lock is tightened down. | 1. | Check to make sure table locks are fully released. |

move. | 2. | Chips have loaded up on bedways. | 2. | Frequently clean away chips that load up during |

|

|

|

| turning operations. |

| 3. | Bedways are dry and in need of lubrication. | 3. | Lubricate bedways and handles. |

| 4. | Longitudinal stops are interfering. | 4. | Check to make sure that stops are floating and not |

|

|

|

| hitting the center stop. |

| 5. | Gibs are too tight. | 5. | Loosen gib screw(s) slightly. |

Gear change | 1. | Gears not aligned in headstock. | 1. | Rotate spindle by hand until gear falls into place. |

levers will not |

|

|

|

|

shift into posi- |

|

|

|

|

tion. |

|

|

|

|

|

|

|

|

|

Motor overheats. | 1. | Motor overloaded. | 1. | Reduce load on motor. |

| 2. | Air circulation through the motor restricted. | 2. | Clean out motor to provide normal air circulation. |

Loud, repetitious | 1. | Gears not aligned in headstock or no back- | 1. | Adjust gears and establish backlash. |

noise coming |

| lash. |

|

|

from machine. | 2. | Broken gear or bad bearing. | 2. | Replace broken gear or bearing. |

| 3. | Workpiece is hitting stationary object. | 3. | Stop lathe immediately and correct interference |

|

|

|

| problem. |

|

|

|

|

|

Tailstock quill | 1. | Quill lock lever is tightened down. | 1. | Turn lever counterclockwise. |

will not feed out |

|

|

|

|

of tailstock. |

|

|

|

|

Motor is loud | 1. | Excessive depth of cut or feed rate. | 1. | Decrease depth of cut or feed rate. |

when cutting. | 2. | RPM or feed rate wrong for cutting | 2. | Refer to RPM feed rate chart for appropriate rates. |

Overheats or |

| operation. |

|

|

bogs down in the | 3. | Cutting tool is dull. | 3. | Sharpen or replace the cutting tool. |

cut. | 4. | Gear setup is too tight, causing them to | 4. | Readjust the gear setup with a small amount of |

|

| bind. |

| backlash so the gears move freely and smoothly |

|

|

|

| when the chuck is rotated by hand. |

SERVICE