M1109 Combo Lathe/Mill

OPERATIONS

Table Travel

The mill table of the Model M1109 can be moved in two

Cross Feed

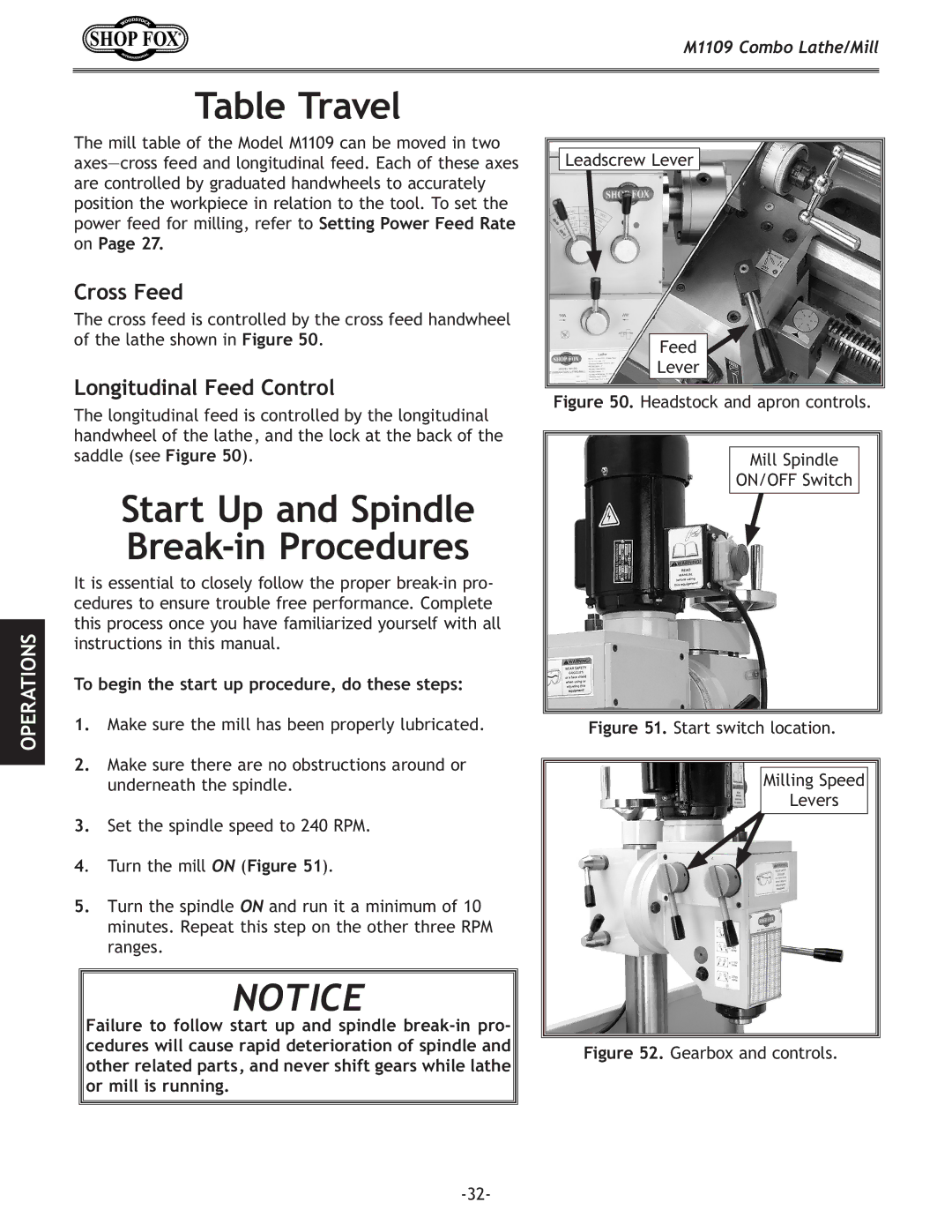

The cross feed is controlled by the cross feed handwheel of the lathe shown in Figure 50.

Longitudinal Feed Control

The longitudinal feed is controlled by the longitudinal handwheel of the lathe, and the lock at the back of the saddle (see Figure 50).

Start Up and Spindle Break-in Procedures

It is essential to closely follow the proper

To begin the start up procedure, do these steps:

1.Make sure the mill has been properly lubricated.

2.Make sure there are no obstructions around or underneath the spindle.

3.Set the spindle speed to 240 RPM.

4. Turn the mill ON (Figure 51).

5.Turn the spindle ON and run it a minimum of 10 minutes. Repeat this step on the other three RPM ranges.

NOTICE

Failure to follow start up and spindle

Leadscrew Lever

Feed ![]()

Lever