ADJUSTMENTS

Table Bed Rollers

The table bed rollers should be set last so they stay out of the way during the other adjustments. The required height of the table bed rollers will vary depending on the type of stock you intend to plane.

As a general rule, table bed roller height should be between 0.002" and 0.006" above the table (see Figure 34). However, some stock may have better results outside of these height settings. Often, a small amount of

To adjust the table bed roller height, do these steps:

1.UNPLUG THE PLANER!

2.Place a straightedge across the length of the table as shown in Figure 35.

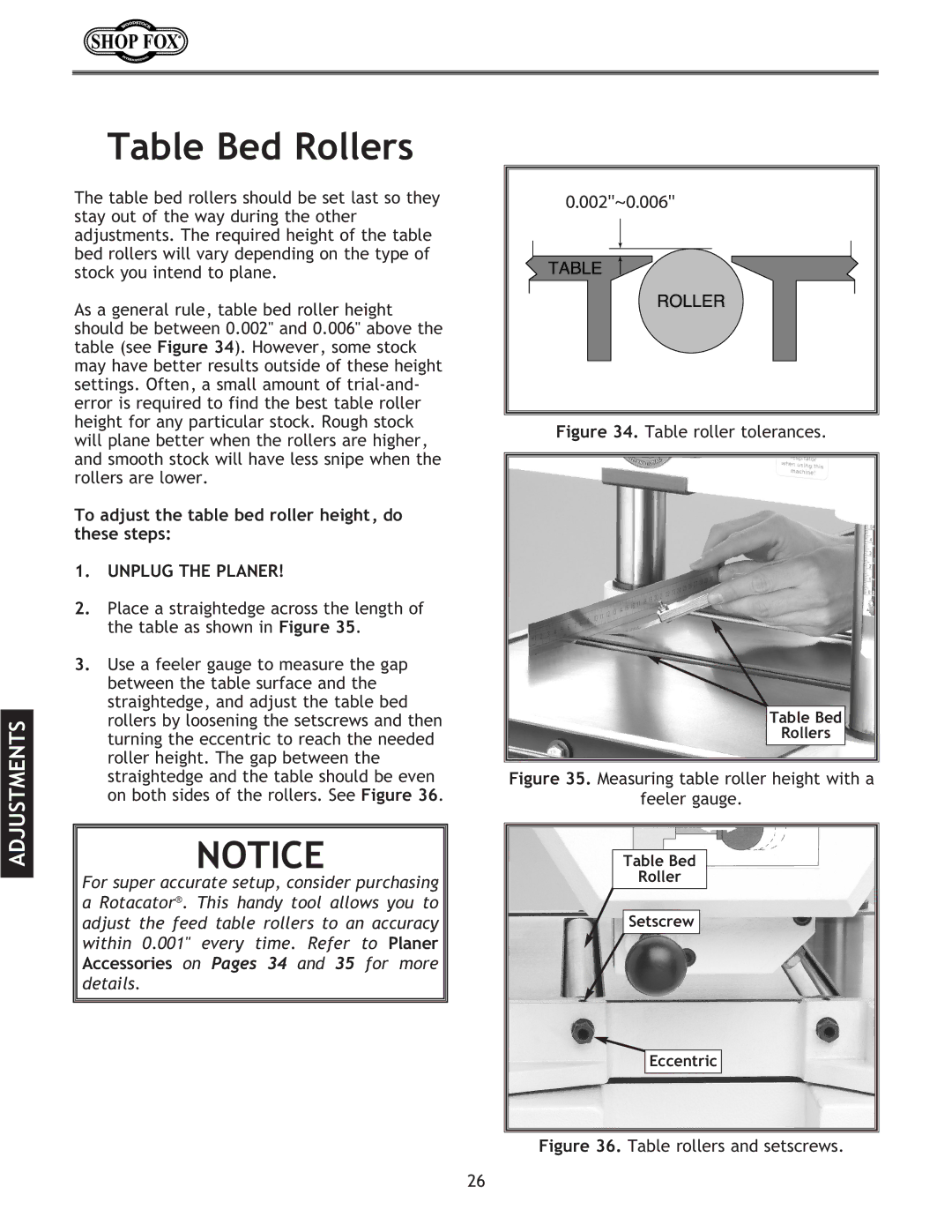

3.Use a feeler gauge to measure the gap between the table surface and the straightedge, and adjust the table bed rollers by loosening the setscrews and then turning the eccentric to reach the needed roller height. The gap between the straightedge and the table should be even on both sides of the rollers. See Figure 36.

NOTICE

For super accurate setup, consider purchasing a Rotacator®. This handy tool allows you to adjust the feed table rollers to an accuracy within 0.001" every time. Refer to Planer Accessories on Pages 34 and 35 for more details.

Figure 34. Table roller tolerances.

Table Bed

Rollers

Figure 35. Measuring table roller height with a

feeler gauge.

Table Bed

Roller

Setscrew

Eccentric

Figure 36. Table rollers and setscrews.

26