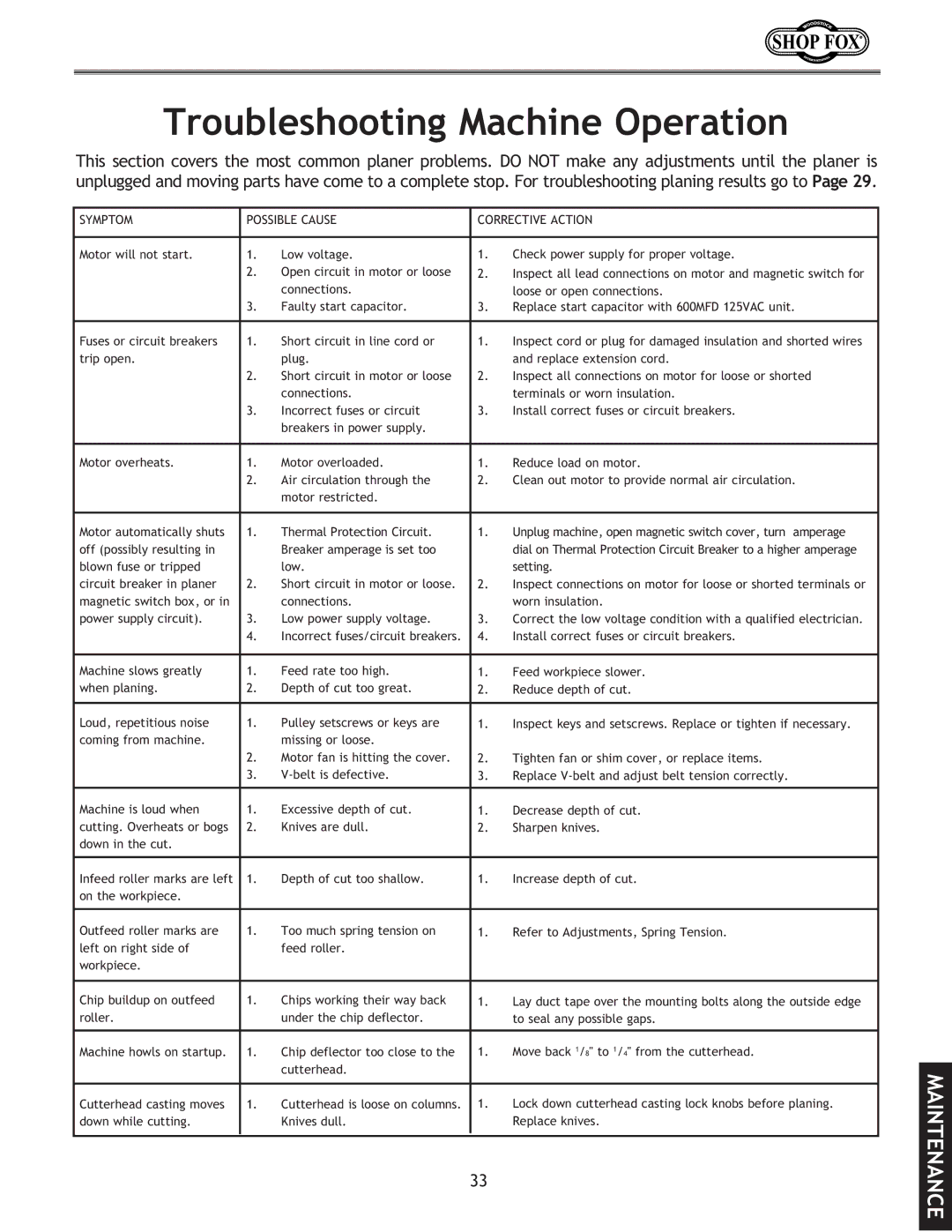

Troubleshooting Machine Operation

This section covers the most common planer problems. DO NOT make any adjustments until the planer is unplugged and moving parts have come to a complete stop. For troubleshooting planing results go to Page 29.

SYMPTOM | POSSIBLE CAUSE | CORRECTIVE ACTION | ||

|

|

|

|

|

Motor will not start. | 1. | Low voltage. | 1. | Check power supply for proper voltage. |

| 2. | Open circuit in motor or loose | 2. | Inspect all lead connections on motor and magnetic switch for |

|

| connections. |

| loose or open connections. |

| 3. | Faulty start capacitor. | 3. | Replace start capacitor with 600MFD 125VAC unit. |

|

|

|

|

|

Fuses or circuit breakers | 1. | Short circuit in line cord or | 1. | Inspect cord or plug for damaged insulation and shorted wires |

trip open. |

| plug. |

| and replace extension cord. |

| 2. | Short circuit in motor or loose | 2. | Inspect all connections on motor for loose or shorted |

|

| connections. |

| terminals or worn insulation. |

| 3. | Incorrect fuses or circuit | 3. | Install correct fuses or circuit breakers. |

|

| breakers in power supply. |

|

|

|

|

|

|

|

Motor overheats. | 1. | Motor overloaded. | 1. | Reduce load on motor. |

| 2. | Air circulation through the | 2. | Clean out motor to provide normal air circulation. |

|

| motor restricted. |

|

|

|

|

|

|

|

Motor automatically shuts | 1. | Thermal Protection Circuit. | 1. | Unplug machine, open magnetic switch cover, turn amperage |

off (possibly resulting in |

| Breaker amperage is set too |

| dial on Thermal Protection Circuit Breaker to a higher amperage |

blown fuse or tripped |

| low. |

| setting. |

circuit breaker in planer | 2. | Short circuit in motor or loose. | 2. | Inspect connections on motor for loose or shorted terminals or |

magnetic switch box, or in |

| connections. |

| worn insulation. |

power supply circuit). | 3. | Low power supply voltage. | 3. | Correct the low voltage condition with a qualified electrician. |

| 4. | Incorrect fuses/circuit breakers. | 4. | Install correct fuses or circuit breakers. |

|

|

|

|

|

Machine slows greatly | 1. | Feed rate too high. | 1. | Feed workpiece slower. |

when planing. | 2. | Depth of cut too great. | 2. | Reduce depth of cut. |

|

|

|

|

|

Loud, repetitious noise | 1. | Pulley setscrews or keys are | 1. | Inspect keys and setscrews. Replace or tighten if necessary. |

coming from machine. |

| missing or loose. |

|

|

| 2. | Motor fan is hitting the cover. | 2. | Tighten fan or shim cover, or replace items. |

| 3. | 3. | Replace | |

|

|

|

|

|

Machine is loud when | 1. | Excessive depth of cut. | 1. | Decrease depth of cut. |

cutting. Overheats or bogs | 2. | Knives are dull. | 2. | Sharpen knives. |

down in the cut. |

|

|

|

|

|

|

|

|

|

Infeed roller marks are left | 1. | Depth of cut too shallow. | 1. | Increase depth of cut. |

on the workpiece. |

|

|

|

|

|

|

|

|

|

Outfeed roller marks are | 1. | Too much spring tension on | 1. | Refer to Adjustments, Spring Tension. |

left on right side of |

| feed roller. |

|

|

workpiece. |

|

|

|

|

|

|

|

|

|

Chip buildup on outfeed | 1. | Chips working their way back | 1. | Lay duct tape over the mounting bolts along the outside edge |

roller. |

| under the chip deflector. |

| to seal any possible gaps. |

|

|

|

|

|

Machine howls on startup. | 1. | Chip deflector too close to the | 1. | Move back 1/8" to 1/4" from the cutterhead. |

|

| cutterhead. |

|

|

|

|

|

|

|

Cutterhead casting moves | 1. | Cutterhead is loose on columns. | 1. | Lock down cutterhead casting lock knobs before planing. |

down while cutting. |

| Knives dull. |

| Replace knives. |

|

|

|

|

|

33

MAINTENANCE