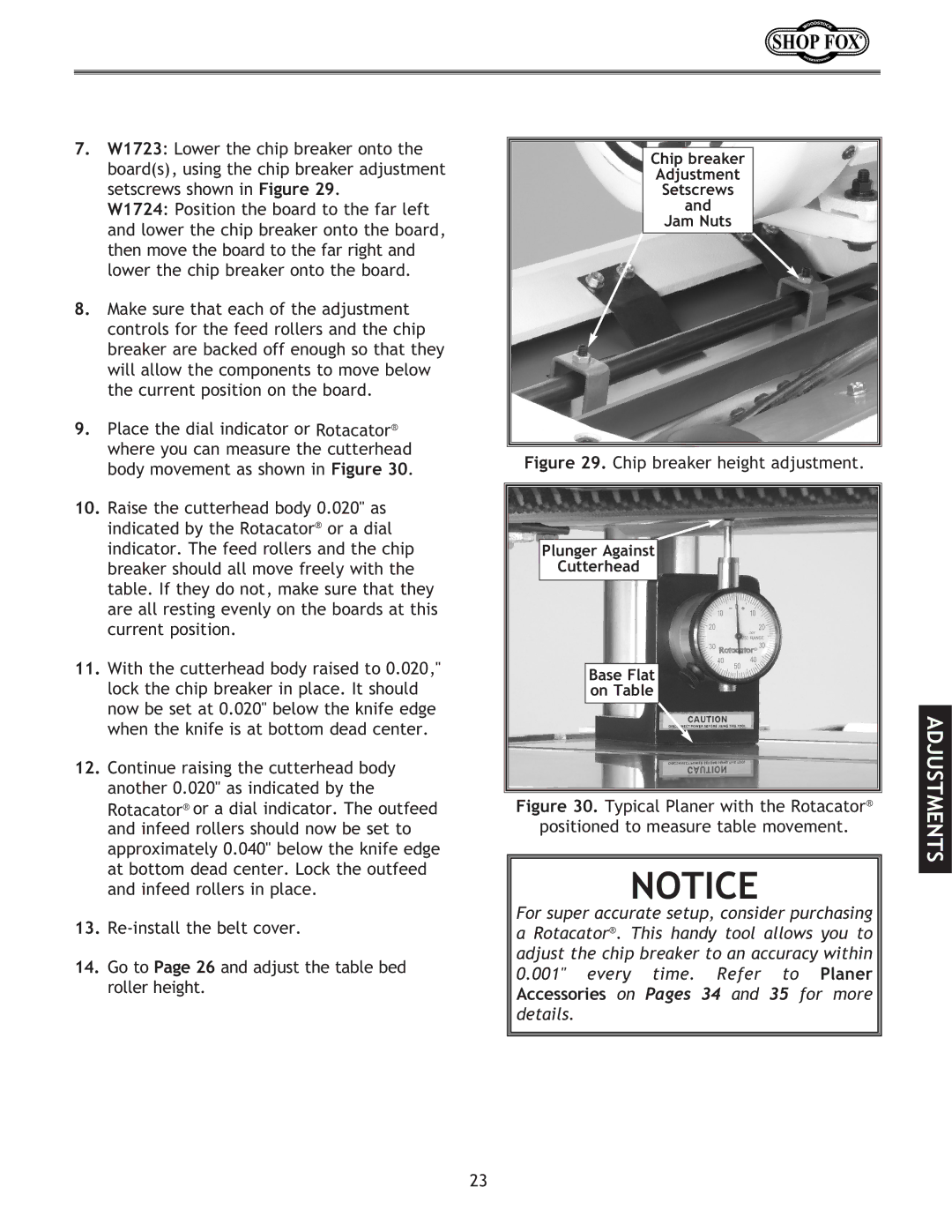

7. | W1723: Lower the chip breaker onto the |

| board(s), using the chip breaker adjustment |

| setscrews shown in Figure 29. |

| W1724: Position the board to the far left |

| and lower the chip breaker onto the board, |

| then move the board to the far right and |

| lower the chip breaker onto the board. |

8. | Make sure that each of the adjustment |

| controls for the feed rollers and the chip |

| breaker are backed off enough so that they |

| will allow the components to move below |

| the current position on the board. |

9. | Place the dial indicator or Rotacator® |

| where you can measure the cutterhead |

| body movement as shown in Figure 30. |

10. | Raise the cutterhead body 0.020" as |

| indicated by the Rotacator® or a dial |

| indicator. The feed rollers and the chip |

| breaker should all move freely with the |

| table. If they do not, make sure that they |

| are all resting evenly on the boards at this |

| current position. |

11. | With the cutterhead body raised to 0.020," |

| lock the chip breaker in place. It should |

| now be set at 0.020" below the knife edge |

| when the knife is at bottom dead center. |

12. | Continue raising the cutterhead body |

| another 0.020" as indicated by the |

| Rotacator® or a dial indicator. The outfeed |

Chip breaker

Adjustment

Setscrews

and

Jam Nuts

Figure 29. Chip breaker height adjustment.

Plunger Against

Cutterhead

Base Flat on Table

Figure 30. Typical Planer with the Rotacator®

ADJUSTMENTS

and infeed rollers should now be set to |

approximately 0.040" below the knife edge |

at bottom dead center. Lock the outfeed |

and infeed rollers in place. |

13. |

14. Go to Page 26 and adjust the table bed |

roller height. |

positioned to measure table movement.

NOTICE

For super accurate setup, consider purchasing a Rotacator®. This handy tool allows you to adjust the chip breaker to an accuracy within 0.001" every time. Refer to Planer Accessories on Pages 34 and 35 for more details.

23