W1754 20" Planer With Mobile Base

Table Parallelism

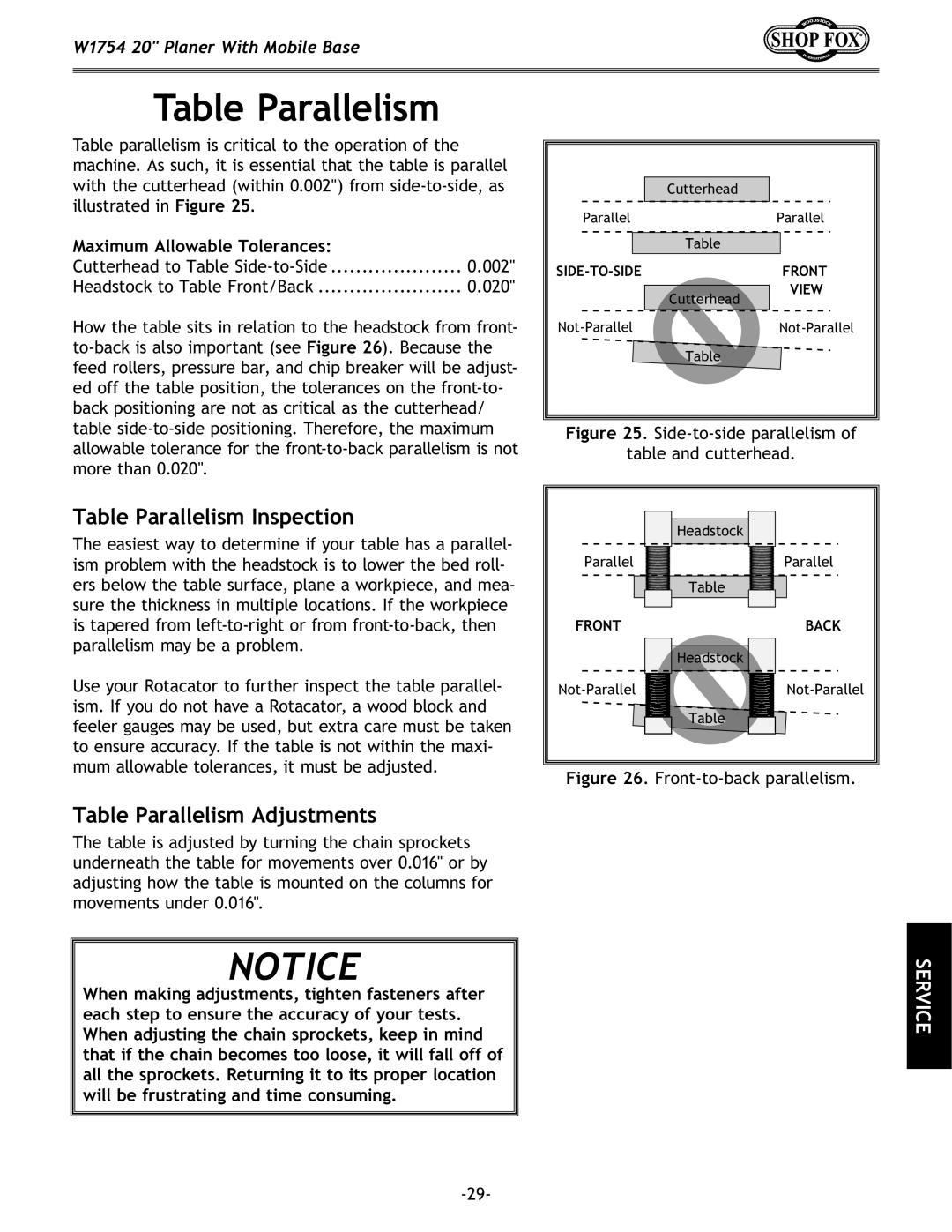

Table parallelism is critical to the operation of the machine. As such, it is essential that the table is parallel with the cutterhead (within 0.002") from

Maximum Allowable Tolerances: | 0.002" |

Cutterhead to Table |

����������

����������������

�����

������������������

Headstock to Table Front/Back | 0.020" |

����������

����

How the table sits in relation to the headstock from front-

Table Parallelism Inspection

The easiest way to determine if your table has a parallel- ism problem with the headstock is to lower the bed roll- ers below the table surface, plane a workpiece, and mea- sure the thickness in multiple locations. If the workpiece is tapered from

Use your Rotacator to further inspect the table parallel- ism. If you do not have a Rotacator, a wood block and feeler gauges may be used, but extra care must be taken to ensure accuracy. If the table is not within the maxi- mum allowable tolerances, it must be adjusted.

Table Parallelism Adjustments

The table is adjusted by turning the chain sprockets underneath the table for movements over 0.016" or by adjusting how the table is mounted on the columns for movements under 0.016".

NOTICE

When making adjustments, tighten fasteners after each step to ensure the accuracy of your tests. When adjusting the chain sprockets, keep in mind that if the chain becomes too loose, it will fall off of all the sprockets. Returning it to its proper location will be frustrating and time consuming.

������������������������

�����![]()

Figure 25. Side-to-side parallelism of

table and cutterhead.

![]() ���������

��������� ![]()

�������� ![]()

![]() ��������

��������

�����

���������

![]() ���������

��������� ![]()

������������������������

�����![]()