W1754 20" Planer With Mobile Base

Chip Deflector Positioning

The chip deflector keeps chips from falling onto the outfeed roller.

Chip Deflector Gap Setting | 1⁄4" |

To adjust the deflector position, do these steps: |

|

1.DISCONNECT THE PLANER FROM THE POWER SOURCE!

2.Put on leather gloves.

3.Remove the dust hood, top cover, and

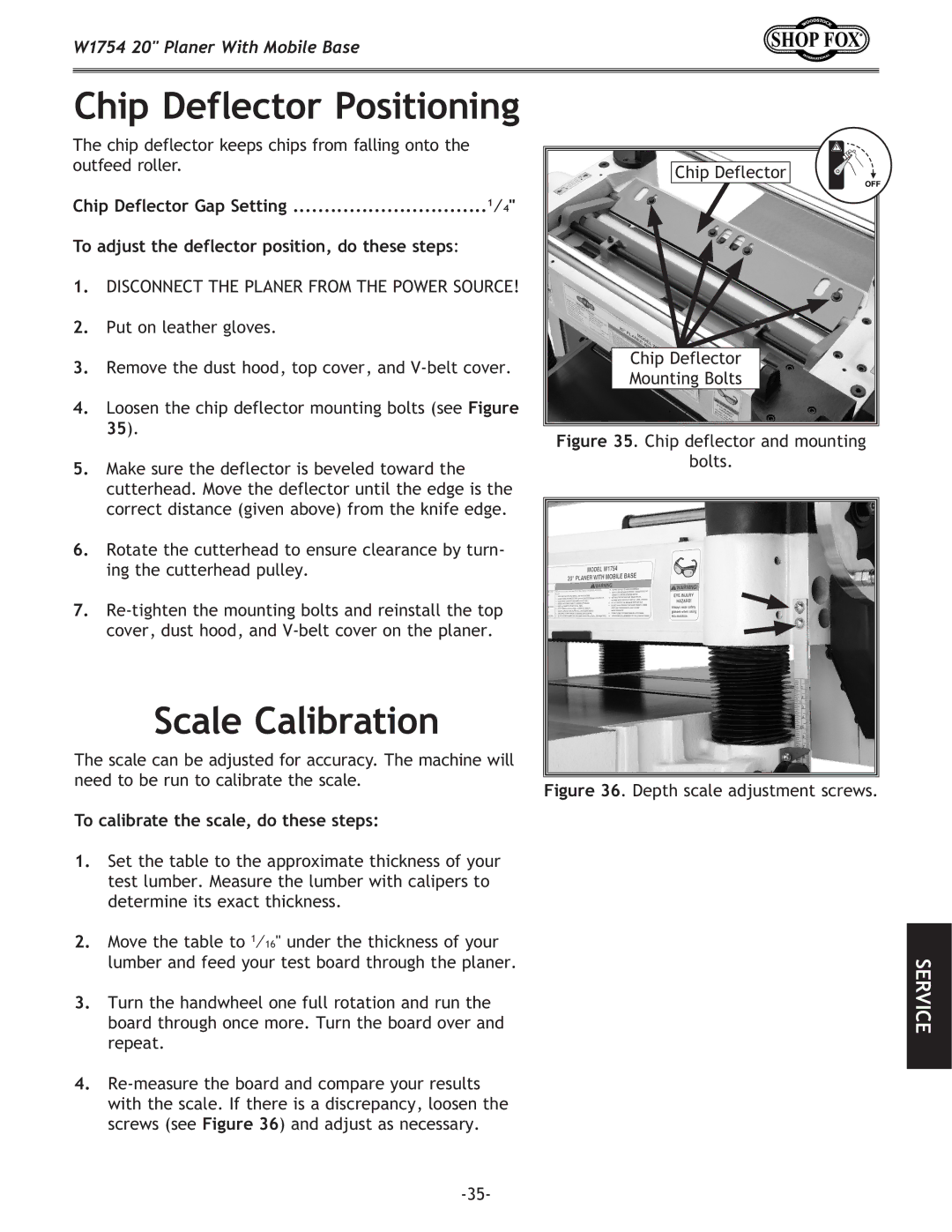

4.Loosen the chip deflector mounting bolts (see Figure 35).

5.Make sure the deflector is beveled toward the cutterhead. Move the deflector until the edge is the correct distance (given above) from the knife edge.

6.Rotate the cutterhead to ensure clearance by turn- ing the cutterhead pulley.

7.

Chip Deflector |

OFF |

Chip Deflector |

Mounting Bolts |

Figure 35. Chip deflector and mounting

bolts.

Scale Calibration |

|

The scale can be adjusted for accuracy. The machine will |

|

need to be run to calibrate the scale. | Figure 36. Depth scale adjustment screws. |

| |

To calibrate the scale, do these steps: |

|

1.Set the table to the approximate thickness of your test lumber. Measure the lumber with calipers to determine its exact thickness.

2.Move the table to 1⁄16" under the thickness of your lumber and feed your test board through the planer.

3.Turn the handwheel one full rotation and run the board through once more. Turn the board over and repeat.

4.