W1772/W1773 37" Drum Sander

V-Belt Service

Tension

New

Proper tension is important for optimum power transmis- sion. However, too much tension may cause premature bearing failure.

The correct

To adjust V-belt tension, do these steps:

1.DISCONNECT POWER TO THE SANDER!

2.Remove the table height handwheel and open the pulley cover.

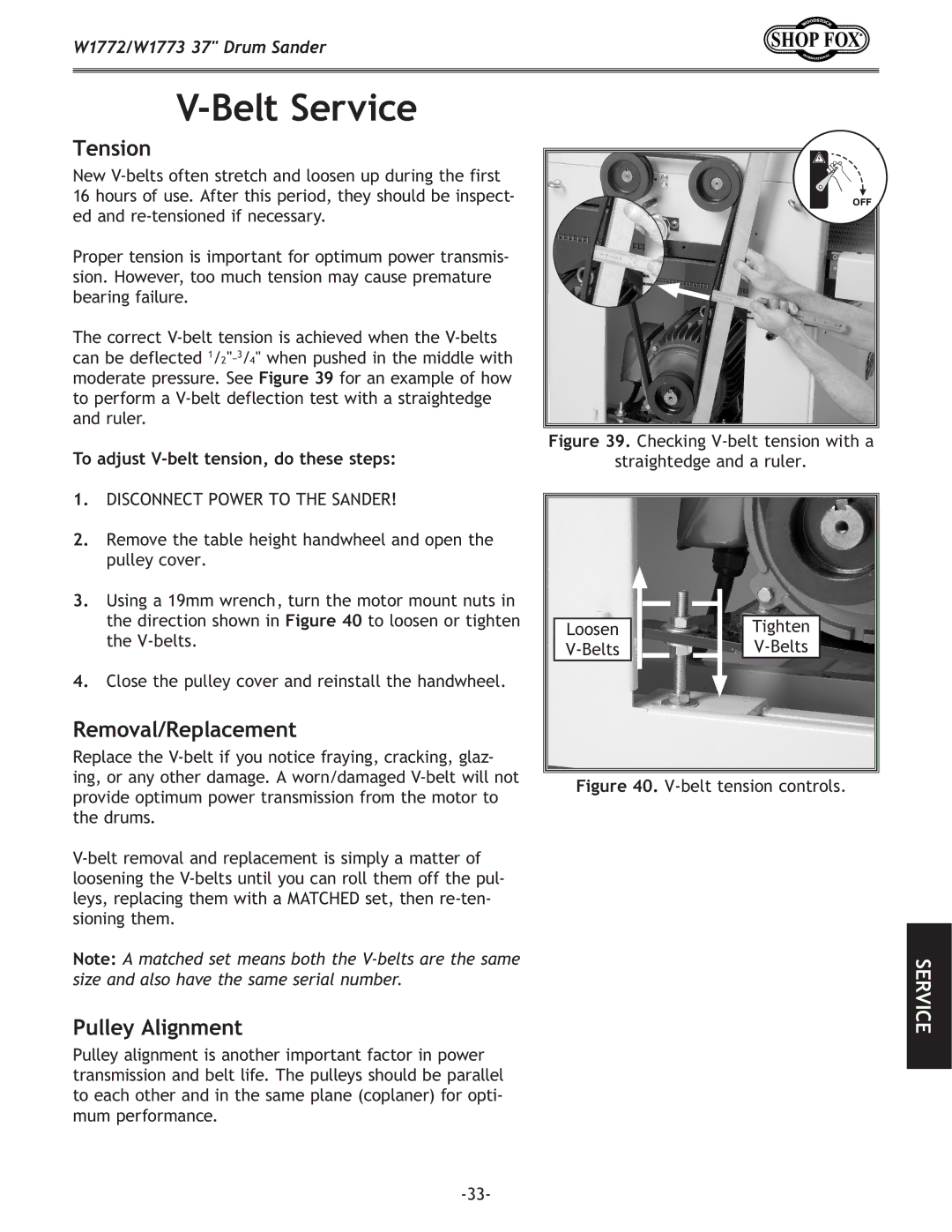

3.Using a 19mm wrench, turn the motor mount nuts in the direction shown in Figure 40 to loosen or tighten the

4.Close the pulley cover and reinstall the handwheel.

Removal/Replacement

Replace the

Note: A matched set means both the

Pulley Alignment

Pulley alignment is another important factor in power transmission and belt life. The pulleys should be parallel to each other and in the same plane (coplaner) for opti- mum performance.

OFF

Figure 39. Checking V-belt tension with a

straightedge and a ruler.

Loosen | Tighten |