| Model W1829 (Mfg. Since 9/11) |

Machine Placement | Cleaning Machine |

SETUP

•Workbench Load: Refer to the Machine Specifications, on Page 3, for the weight and footprint specifications of your machine. Some workbenches may require additional reinforcement to support both the weight of the machine and materials.

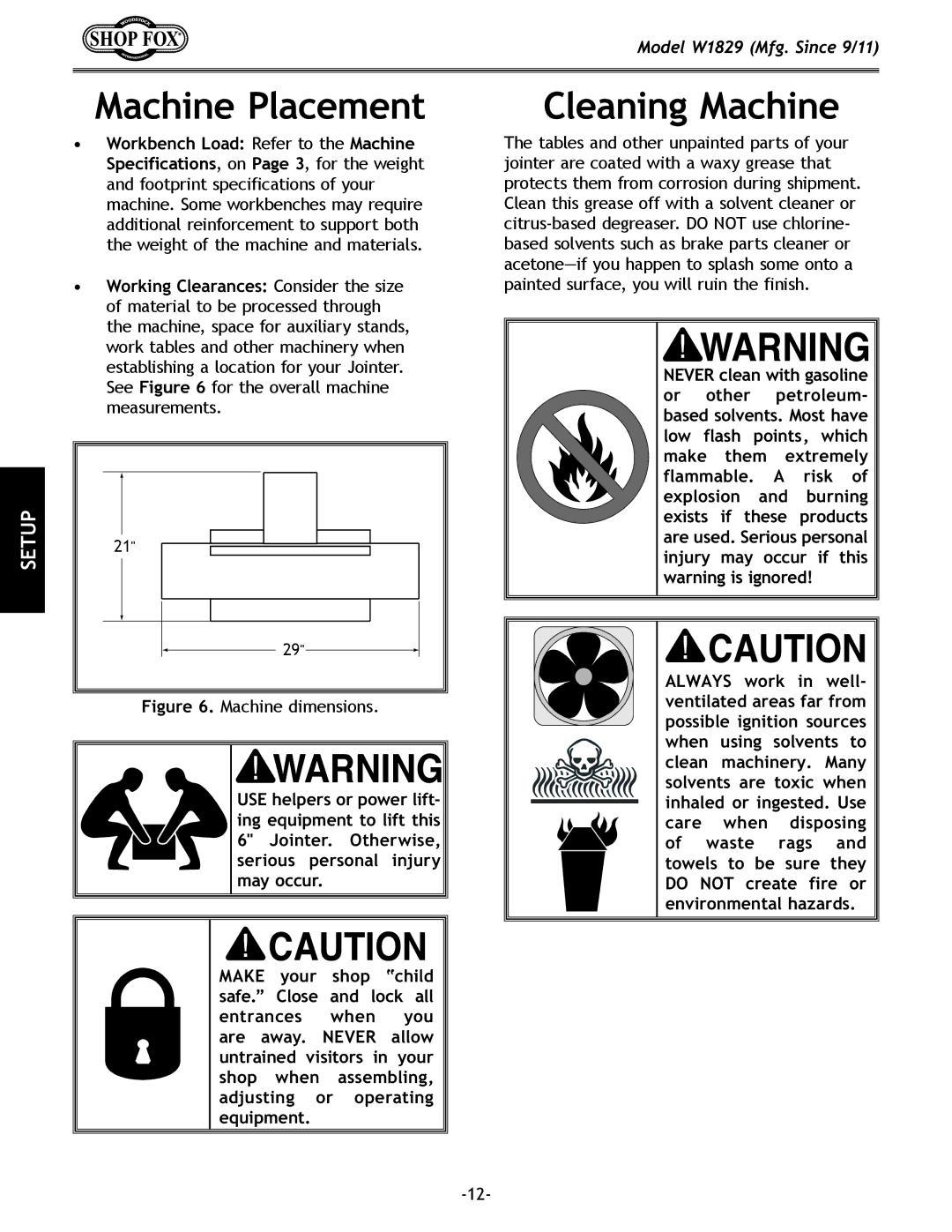

•Working Clearances: Consider the size of material to be processed through the machine, space for auxiliary stands, work tables and other machinery when establishing a location for your Jointer. See Figure 6 for the overall machine measurements.

21"

29"

Figure 6. Machine dimensions.

USE helpers or power lift- ing equipment to lift this 6" Jointer. Otherwise, serious personal injury may occur.

MAKE your shop “child safe.” Close and lock all entrances when you are away. NEVER allow untrained visitors in your shop when assembling, adjusting or operating equipment.

The tables and other unpainted parts of your jointer are coated with a waxy grease that protects them from corrosion during shipment. Clean this grease off with a solvent cleaner or

NEVER clean with gasoline or other petroleum- based solvents. Most have low flash points, which make them extremely flammable. A risk of explosion and burning exists if these products are used. Serious personal injury may occur if this warning is ignored!

ALWAYS work in well- ventilated areas far from possible ignition sources when using solvents to clean machinery. Many solvents are toxic when inhaled or ingested. Use care when disposing of waste rags and towels to be sure they DO NOT create fire or environmental hazards.