Model W1829 (Mfg. Since 9/11)

6.Move the straightedge to position A, as shown in ![]() Figure 39. Turn the jack screw nearest the fence

Figure 39. Turn the jack screw nearest the fence

counterclockwise until the end of the knife touches Cutterhead knives are sharp and

the straightedge. |

|

| laceration injuries may occur. Use | ||||||||||

|

|

| |||||||||||

7. Move the straightedge to position B, as shown in |

|

| caution when handling the cutterhead | ||||||||||

|

| knives. | |||||||||||

Figure 39. Turn the jack screw nearest the guard |

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |

counterclockwise until the end of the knife touches |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

the straightedge. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

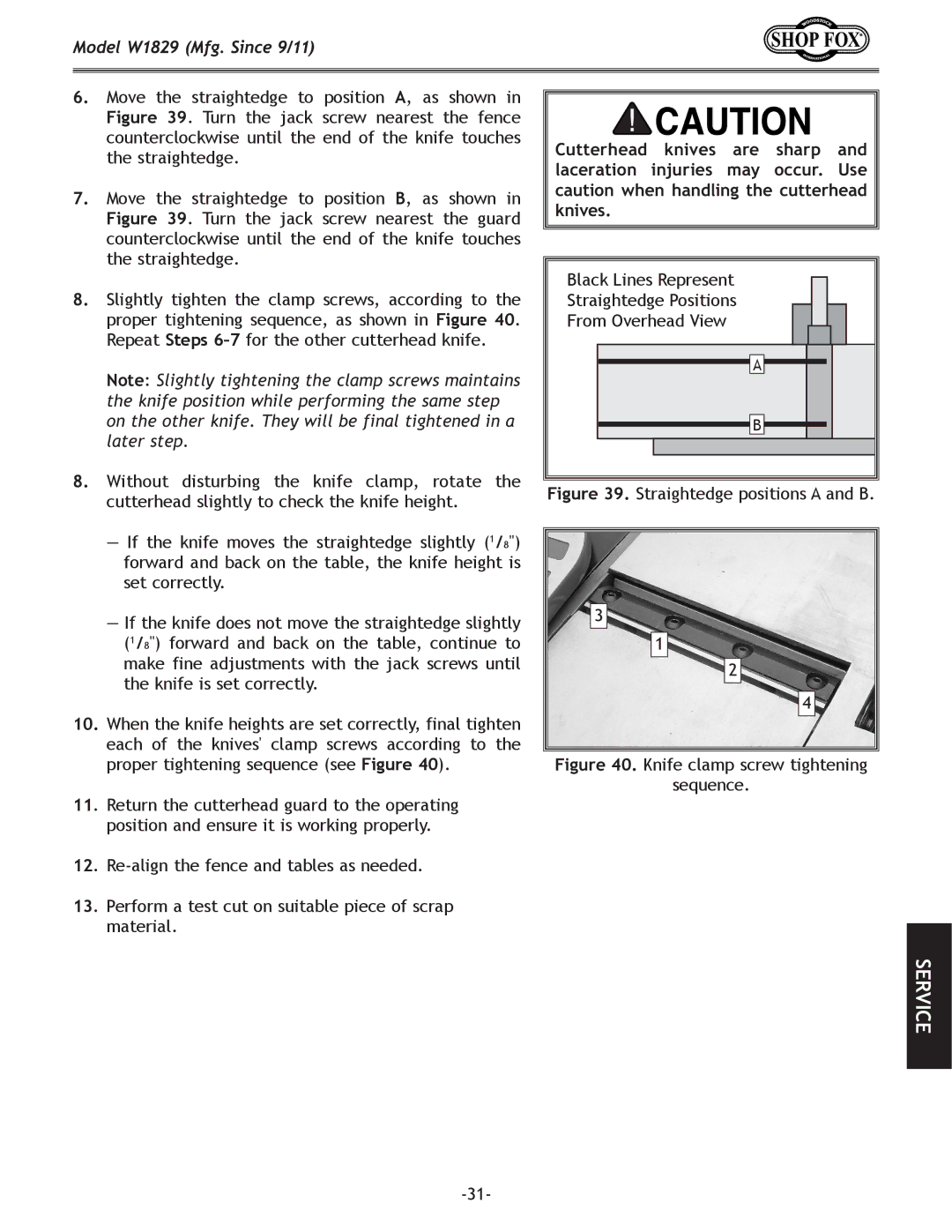

| Black Lines Represent |

|

|

|

|

| ||||||

8. Slightly tighten the clamp screws, according to the |

|

|

|

|

| ||||||||

|

|

|

|

| |||||||||

|

| Straightedge Positions |

|

|

|

|

| ||||||

proper tightening sequence, as shown in Figure 40. |

|

| From Overhead View |

|

|

|

|

| |||||

Repeat Steps |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Note: Slightly tightening the clamp screws maintains |

|

|

|

|

| A |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| |

the knife position while performing the same step |

|

|

|

|

|

|

|

|

|

|

|

|

|

on the other knife. They will be final tightened in a |

|

|

|

|

| B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

later step. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.Without disturbing the knife clamp, rotate the Figure 39. Straightedge positions A and B.

cutterhead slightly to check the knife height.

—If the knife moves the straightedge slightly (1/8") forward and back on the table, the knife height is set correctly.

—If the knife does not move the straightedge slightly (1/8") forward and back on the table, continue to make fine adjustments with the jack screws until the knife is set correctly.

10.When the knife heights are set correctly, final tighten each of the knives' clamp screws according to the proper tightening sequence (see Figure 40).

11.Return the cutterhead guard to the operating position and ensure it is working properly.

12.

13.Perform a test cut on suitable piece of scrap material.

3

1

2

4

Figure 40. Knife clamp screw tightening

sequence.

SERVICE