Model W1829 (Mfg. Since 9/11)

Stock Inspection

& Requirements

Here are some rules to follow when choosing and jointing stock:

•DO NOT joint or surface plane stock that contains loose knots. Injury to the operator or damage to the workpiece can occur if the knots become dislodged during the cutting operation.

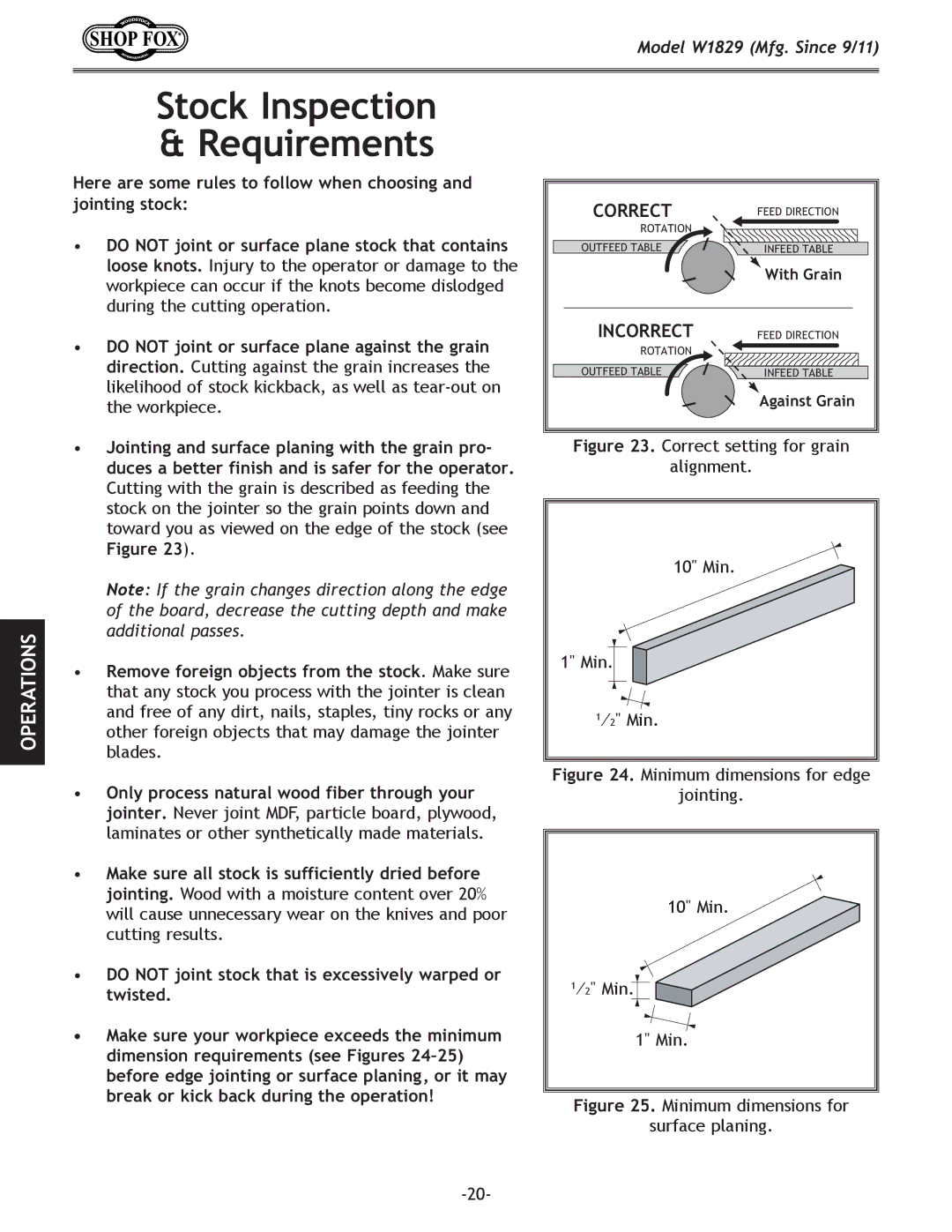

•DO NOT joint or surface plane against the grain direction. Cutting against the grain increases the likelihood of stock kickback, as well as

CORRECT | FEED DIRECTION |

ROTATION |

|

OUTFEED TABLE | INFEED TABLE |

| With Grain |

INCORRECT | FEED DIRECTION |

ROTATION |

|

OUTFEED TABLE | INFEED TABLE |

| Against Grain |

OPERATIONS

•Jointing and surface planing with the grain pro- duces a better finish and is safer for the operator.

Cutting with the grain is described as feeding the stock on the jointer so the grain points down and toward you as viewed on the edge of the stock (see

Figure 23).

Note: If the grain changes direction along the edge of the board, decrease the cutting depth and make additional passes.

•Remove foreign objects from the stock. Make sure that any stock you process with the jointer is clean and free of any dirt, nails, staples, tiny rocks or any other foreign objects that may damage the jointer blades.

•Only process natural wood fiber through your jointer. Never joint MDF, particle board, plywood, laminates or other synthetically made materials.

•Make sure all stock is sufficiently dried before jointing. Wood with a moisture content over 20% will cause unnecessary wear on the knives and poor cutting results.

•DO NOT joint stock that is excessively warped or twisted.

•Make sure your workpiece exceeds the minimum dimension requirements (see Figures

Figure 23. Correct setting for grain

alignment.

10" Min. |

1" Min. |

1⁄2" Min. |

Figure 24. Minimum dimensions for edge

jointing.

10" Min.

1⁄2" Min.

1" Min.