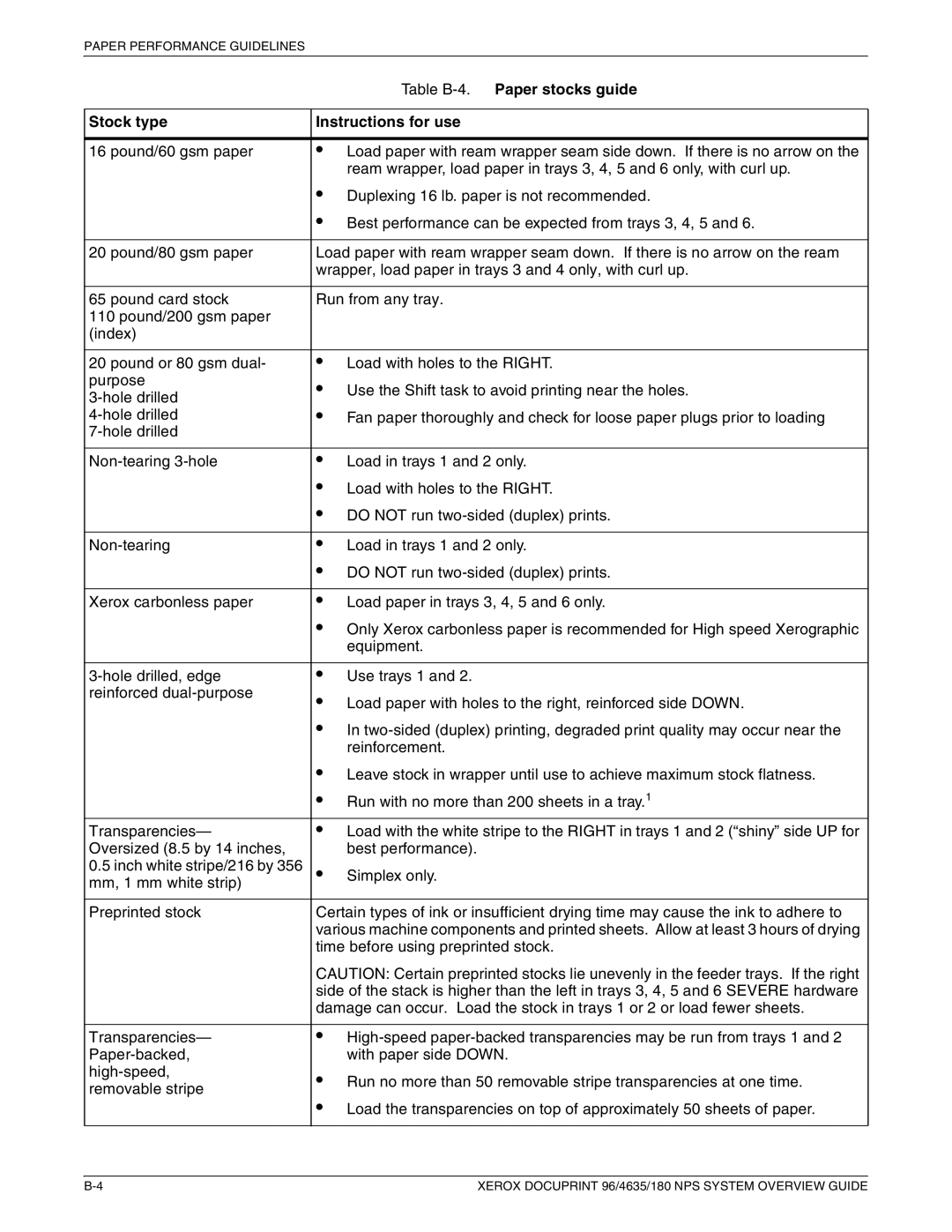

PAPER PERFORMANCE GUIDELINES

|

| Table | |

|

| ||

Stock type | Instructions for use | ||

|

|

| |

16 pound/60 gsm paper | • | Load paper with ream wrapper seam side down. If there is no arrow on the | |

|

| ream wrapper, load paper in trays 3, 4, 5 and 6 only, with curl up. | |

| • Duplexing 16 lb. paper is not recommended. | ||

| • Best performance can be expected from trays 3, 4, 5 and 6. | ||

|

| ||

20 pound/80 gsm paper | Load paper with ream wrapper seam down. If there is no arrow on the ream | ||

| wrapper, load paper in trays 3 and 4 only, with curl up. | ||

|

| ||

65 pound card stock | Run from any tray. | ||

110 pound/200 gsm paper |

|

| |

(index) |

|

| |

|

| ||

20 pound or 80 gsm dual- | • Load with holes to the RIGHT. | ||

purpose | • Use the Shift task to avoid printing near the holes. | ||

• Fan paper thoroughly and check for loose paper plugs prior to loading | |||

|

| ||

|

| ||

• Load in trays 1 and 2 only. | |||

| • Load with holes to the RIGHT. | ||

| • DO NOT run | ||

|

| ||

• Load in trays 1 and 2 only. | |||

| • DO NOT run | ||

|

| ||

Xerox carbonless paper | • Load paper in trays 3, 4, 5 and 6 only. | ||

| • Only Xerox carbonless paper is recommended for High speed Xerographic | ||

|

| equipment. | |

|

| ||

• Use trays 1 and 2. | |||

reinforced | • Load paper with holes to the right, reinforced side DOWN. | ||

| |||

| • In | ||

|

| reinforcement. | |

| • Leave stock in wrapper until use to achieve maximum stock flatness. | ||

| • Run with no more than 200 sheets in a tray.1 | ||

|

| ||

Transparencies— | • Load with the white stripe to the RIGHT in trays 1 and 2 (“shiny” side UP for | ||

Oversized (8.5 by 14 inches, |

| best performance). | |

0.5 inch white stripe/216 by 356 | • | Simplex only. | |

mm, 1 mm white strip) |

|

| |

Preprinted stock | Certain types of ink or insufficient drying time may cause the ink to adhere to | ||

| various machine components and printed sheets. Allow at least 3 hours of drying | ||

| time before using preprinted stock. | ||

| CAUTION: Certain preprinted stocks lie unevenly in the feeder trays. If the right | ||

| side of the stack is higher than the left in trays 3, 4, 5 and 6 SEVERE hardware | ||

| damage can occur. Load the stock in trays 1 or 2 or load fewer sheets. | ||

|

| ||

Transparencies— | • | ||

| with paper side DOWN. | ||

• Run no more than 50 removable stripe transparencies at one time. | |||

removable stripe | |||

• Load the transparencies on top of approximately 50 sheets of paper. | |||

| |||

|

|

| |

XEROX DOCUPRINT 96/4635/180 NPS SYSTEM OVERVIEW GUIDE |