FORM

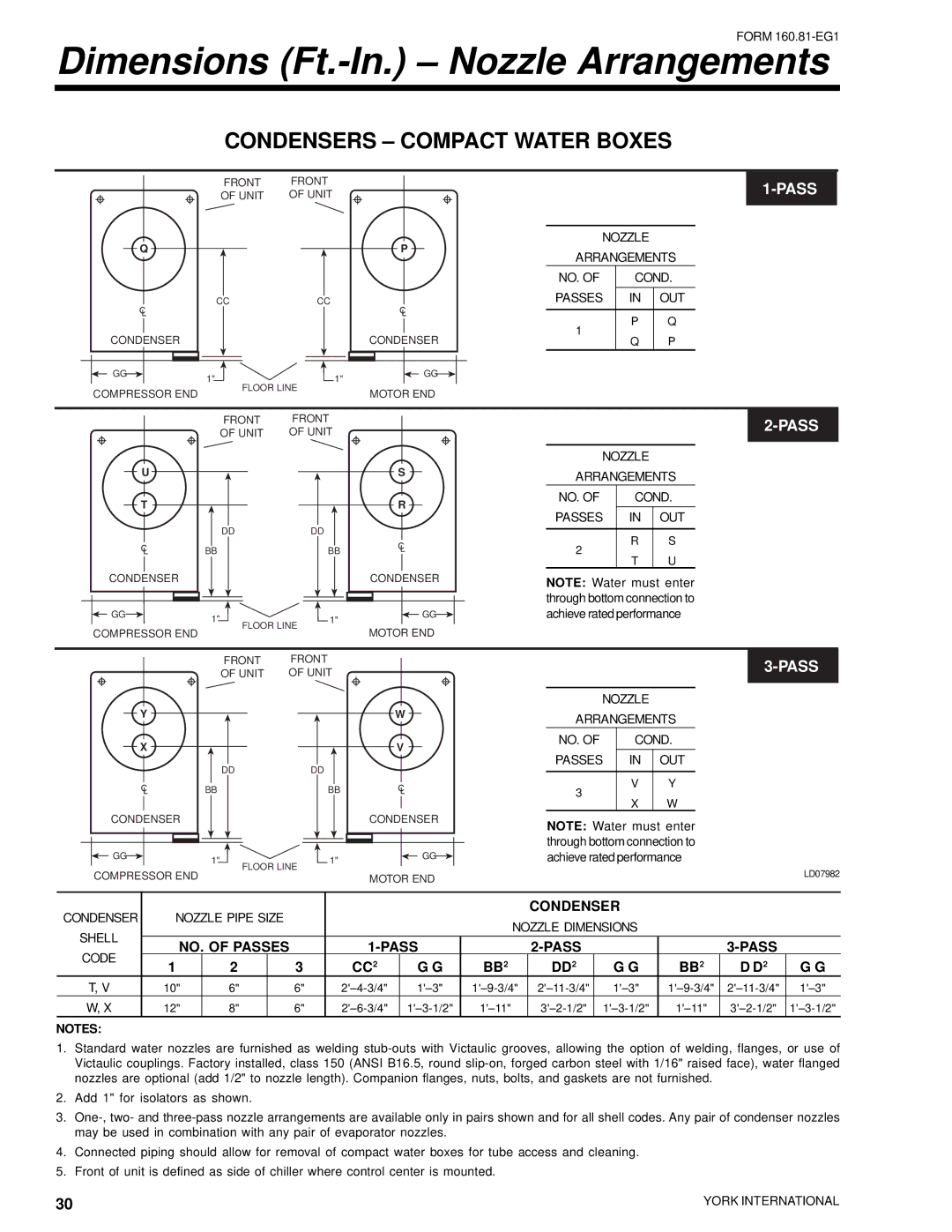

Dimensions (Ft.-In.) – Nozzle Arrangements

CONDENSERS – COMPACT WATER BOXES

FRONT | FRONT |

OF UNIT | OF UNIT |

1-PASS

NOZZLE

Q |

|

|

| P | ARRANGEMENTS | ||

|

|

|

|

| |||

|

|

|

|

| NO. OF | COND. | |

| CC | CC |

|

| PASSES | IN | OUT |

|

|

|

|

| 1 | P | Q |

CONDENSER |

|

|

| CONDENSER | Q | P | |

|

|

|

| ||||

GG | 1" |

| 1" | GG |

|

|

|

| FLOOR LINE |

|

|

|

| ||

COMPRESSOR END |

|

| MOTOR END |

|

|

| |

|

|

|

|

|

| ||

| FRONT | FRONT |

| |

| OF UNIT | OF UNIT |

| |

U |

|

|

| S |

T |

|

|

| R |

| DD |

| DD |

|

| BB |

| BB |

|

CONDENSER |

|

|

| CONDENSER |

GG | 1" |

| 1" | GG |

|

|

| ||

COMPRESSOR END | FLOOR LINE |

| MOTOR END | |

|

|

| ||

2-PASS

NOZZLE

ARRANGEMENTS

NO. OF | COND. | ||

PASSES | IN | OUT | |

2 | R | S | |

T | U | ||

| |||

NOTE: Water must enter through bottom connection to achieve rated performance

FRONT | FRONT |

| |||

OF UNIT | OF UNIT | ||||

| |||||

|

|

|

|

| |

NOZZLE

Y |

|

| W |

X |

|

| V |

| DD | DD |

|

| BB | BB |

|

CONDENSER |

|

| CONDENSER |

GG | 1" | 1" | GG |

|

| ||

COMPRESSOR END |

| FLOOR LINE |

|

|

| MOTOR END |

ARRANGEMENTS

NO. OF | COND. | ||

PASSES | IN | OUT | |

3 | V | Y | |

X | W | ||

| |||

NOTE: Water must enter through bottom connection to achieve rated performance

LD07982

CONDENSER | NOZZLE PIPE SIZE |

|

|

|

| CONDENSER |

|

|

| |||

|

|

| NOZZLE DIMENSIONS |

|

|

| ||||||

SHELL |

|

|

|

|

|

|

|

|

| |||

NO. OF PASSES |

|

|

|

|

| |||||||

CODE |

|

|

|

|

| |||||||

1 | 2 |

| 3 | CC2 | G G | BB2 | DD2 | G G | BB2 | D D2 | G G | |

|

| |||||||||||

T, V | 10" | 6" |

| 6" |

|

| ||||||

W, X | 12" | 8" |

| 6" |

| |||||||

NOTES:

1.Standard water nozzles are furnished as welding

2.Add 1" for isolators as shown.

3.

4.Connected piping should allow for removal of compact water boxes for tube access and cleaning.

5.Front of unit is defined as side of chiller where control center is mounted.

30 | YORK INTERNATIONAL |

|