FORM

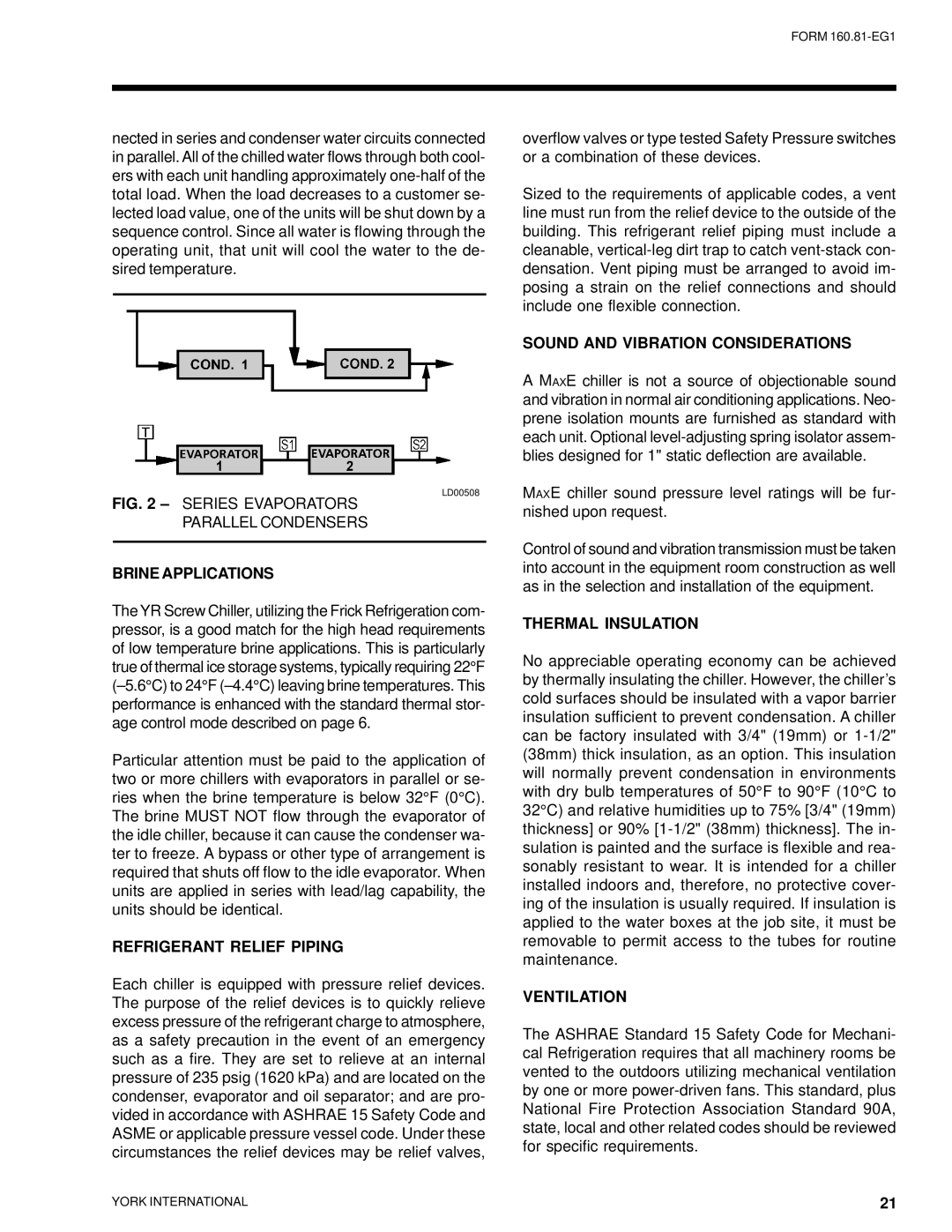

nected in series and condenser water circuits connected in parallel. All of the chilled water flows through both cool- ers with each unit handling approximately

overflow valves or type tested Safety Pressure switches or a combination of these devices.

Sized to the requirements of applicable codes, a vent line must run from the relief device to the outside of the building. This refrigerant relief piping must include a cleanable,

SOUND AND VIBRATION CONSIDERATIONS

A MAXE chiller is not a source of objectionable sound and vibration in normal air conditioning applications. Neo- prene isolation mounts are furnished as standard with each unit. Optional

FIG. 2 – SERIES EVAPORATORS PARALLEL CONDENSERS

BRINE APPLICATIONS

LD00508

MAXE chiller sound pressure level ratings will be fur- nished upon request.

Control of sound and vibration transmission must be taken into account in the equipment room construction as well as in the selection and installation of the equipment.

The YR Screw Chiller, utilizing the Frick Refrigeration com- pressor, is a good match for the high head requirements of low temperature brine applications. This is particularly true of thermal ice storage systems, typically requiring 22°F

Particular attention must be paid to the application of two or more chillers with evaporators in parallel or se- ries when the brine temperature is below 32°F (0°C). The brine MUST NOT flow through the evaporator of the idle chiller, because it can cause the condenser wa- ter to freeze. A bypass or other type of arrangement is required that shuts off flow to the idle evaporator. When units are applied in series with lead/lag capability, the units should be identical.

REFRIGERANT RELIEF PIPING

Each chiller is equipped with pressure relief devices. The purpose of the relief devices is to quickly relieve excess pressure of the refrigerant charge to atmosphere, as a safety precaution in the event of an emergency such as a fire. They are set to relieve at an internal pressure of 235 psig (1620 kPa) and are located on the condenser, evaporator and oil separator; and are pro- vided in accordance with ASHRAE 15 Safety Code and ASME or applicable pressure vessel code. Under these circumstances the relief devices may be relief valves,

THERMAL INSULATION

No appreciable operating economy can be achieved by thermally insulating the chiller. However, the chiller’s cold surfaces should be insulated with a vapor barrier insulation sufficient to prevent condensation. A chiller can be factory insulated with 3/4" (19mm) or

VENTILATION

The ASHRAE Standard 15 Safety Code for Mechani- cal Refrigeration requires that all machinery rooms be vented to the outdoors utilizing mechanical ventilation by one or more

YORK INTERNATIONAL | 21 |