PSJ2300 specifications

The Zenoah PSJ2300 is a high-performance handheld blower designed for professionals and landscaping enthusiasts who demand reliability and efficiency in their tools. Engineered with advanced technologies, the PSJ2300 stands out in the crowded market of outdoor power equipment, making it a go-to choice for various applications such as clearing debris, leaves, and grass clippings.One of the main features of the Zenoah PSJ2300 is its powerful 23cc two-stroke engine, which delivers impressive blowing performance while maintaining a relatively lightweight design. This engine strikes a perfect balance between power and fuel efficiency, allowing users to operate the blower for extended periods without frequent refueling. The innovative design also ensures that the engine operates smoothly, reducing vibrations and improving overall user comfort during operation.

The blower's air volume output is a notable characteristic that enhances its performance. The PSJ2300 can achieve an air volume of 700 cubic feet per minute (CFM) at a maximum airspeed of 140 miles per hour (MPH), making it highly effective for tackling even the most stubborn debris. Whether you are dealing with wet leaves or compacted grass, the Zenoah PSJ2300 delivers consistent results.

Another key feature of the PSJ2300 is its ergonomic design. The blower is equipped with an adjustable handle that provides users with the flexibility to find their most comfortable grip. This design consideration reduces operator fatigue, allowing for prolonged use without discomfort. Additionally, the lightweight construction ensures that even extended usage can be completed without straining the user.

The Zenoah PSJ2300 also incorporates advanced anti-vibration technology, further enhancing user experience. The innovative damping system minimizes fatigue during long periods of use, allowing for precise control while reducing stress on the hands and arms. This feature is particularly appreciated by professional landscapers who often rely on this equipment for hours on end.

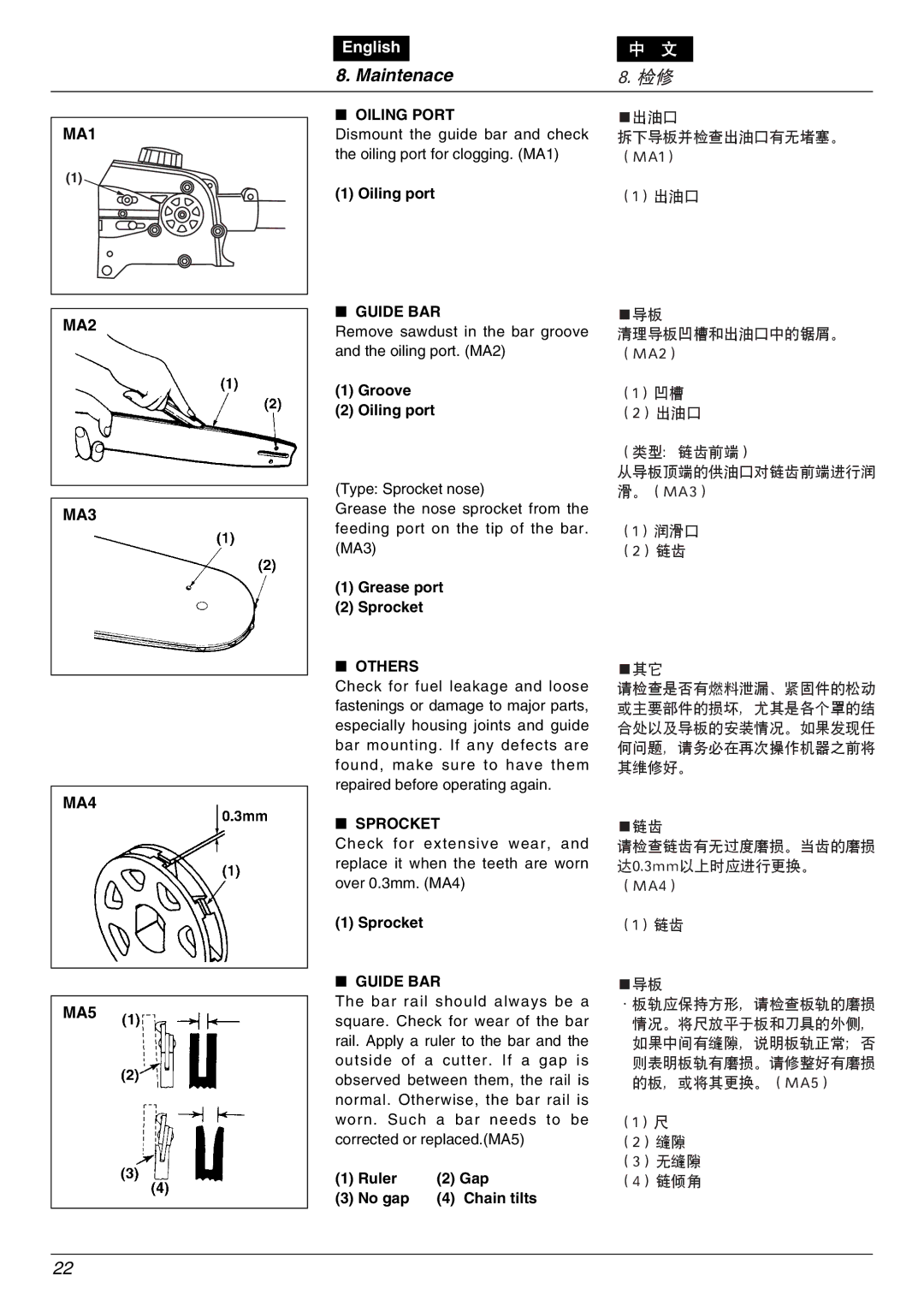

Maintenance is made simple with the PSJ2300, as it is designed for easy access to essential components. This ease of maintenance contributes to the longevity and reliability of the blower, ensuring that it remains a valuable tool in any landscaping arsenal.

In summary, the Zenoah PSJ2300 is a powerful and efficient handheld blower, featuring a robust two-stroke engine, impressive air volume output, ergonomic design, and user-friendly maintenance. With its blend of performance, comfort, and durability, it proves to be a reliable choice for both professional and residential use, making outdoor cleanup tasks easier and more efficient.