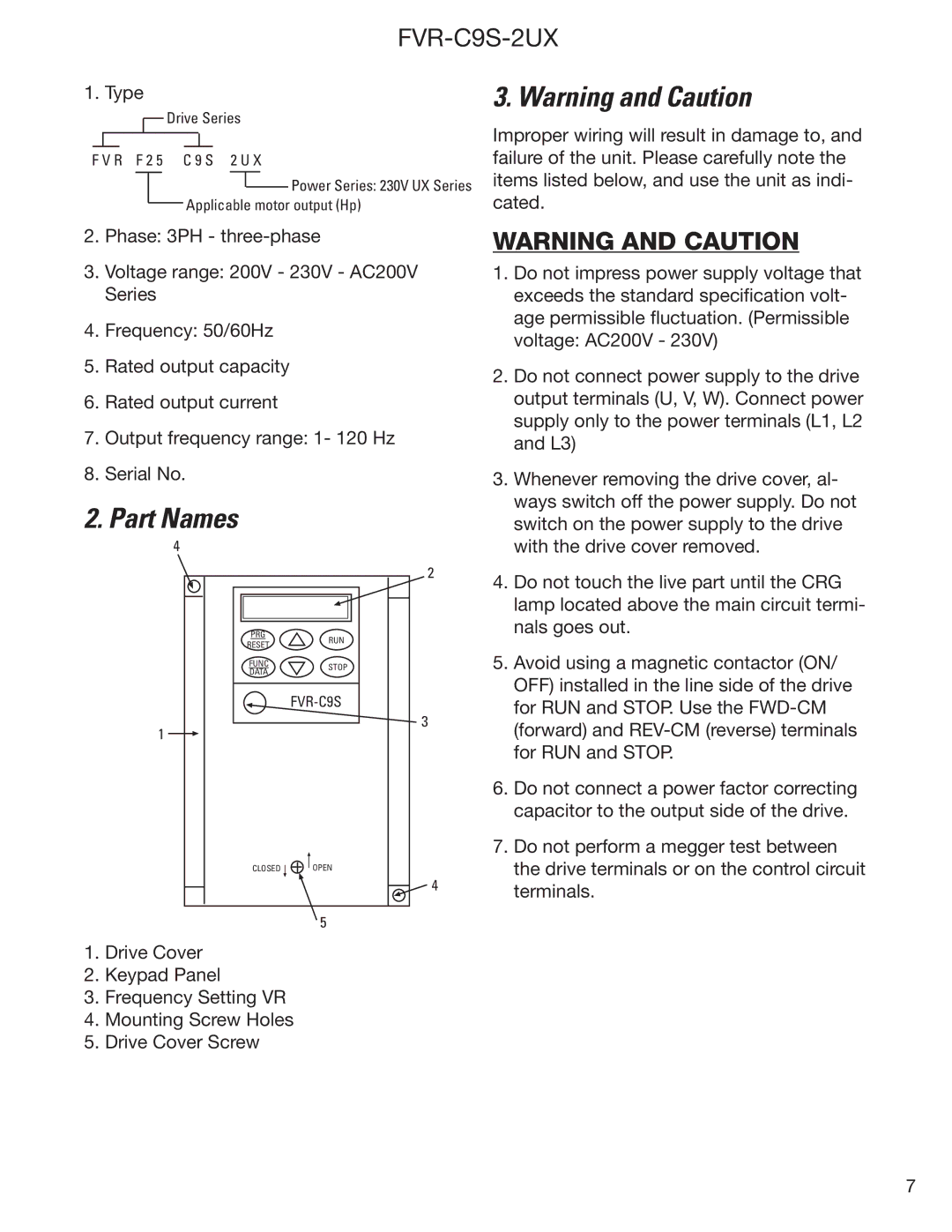

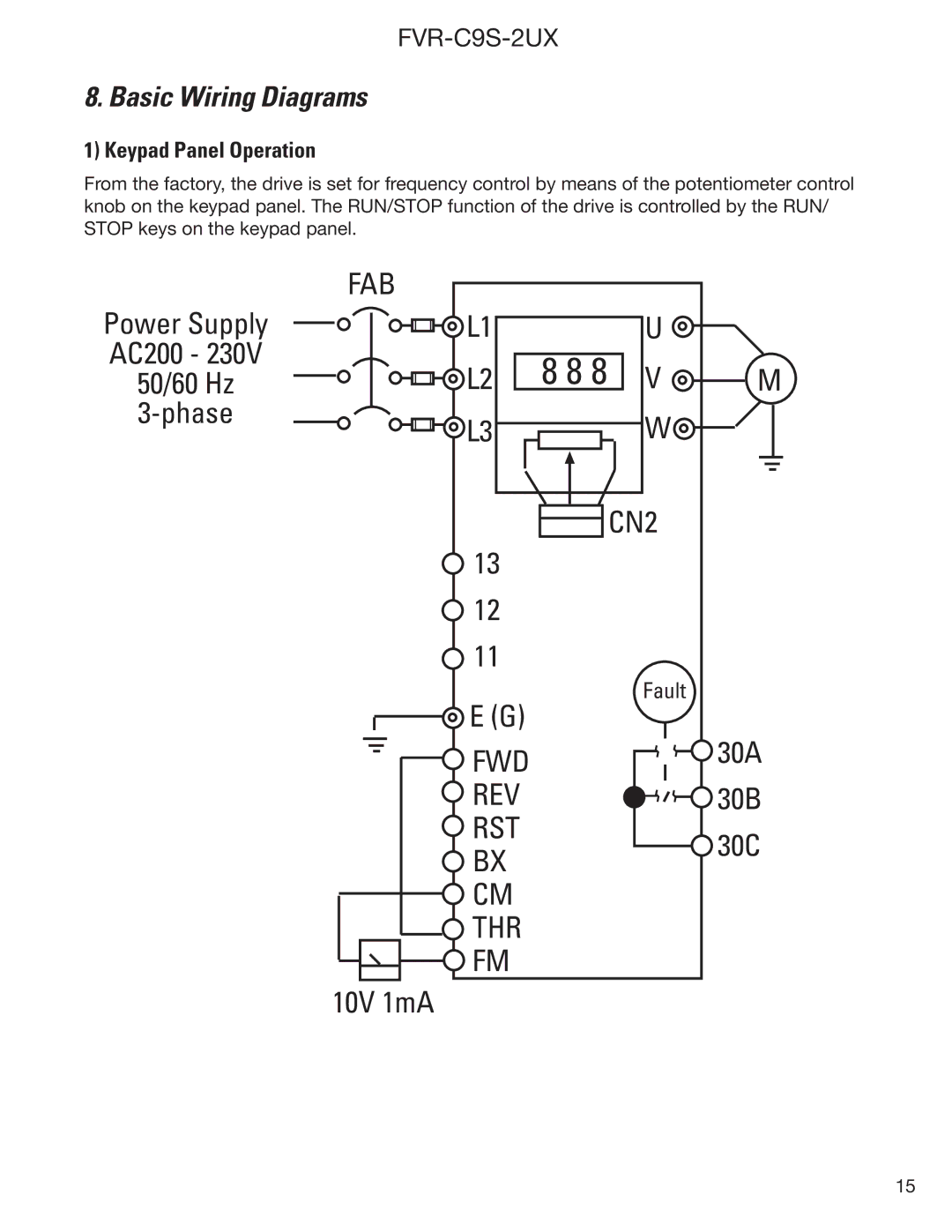

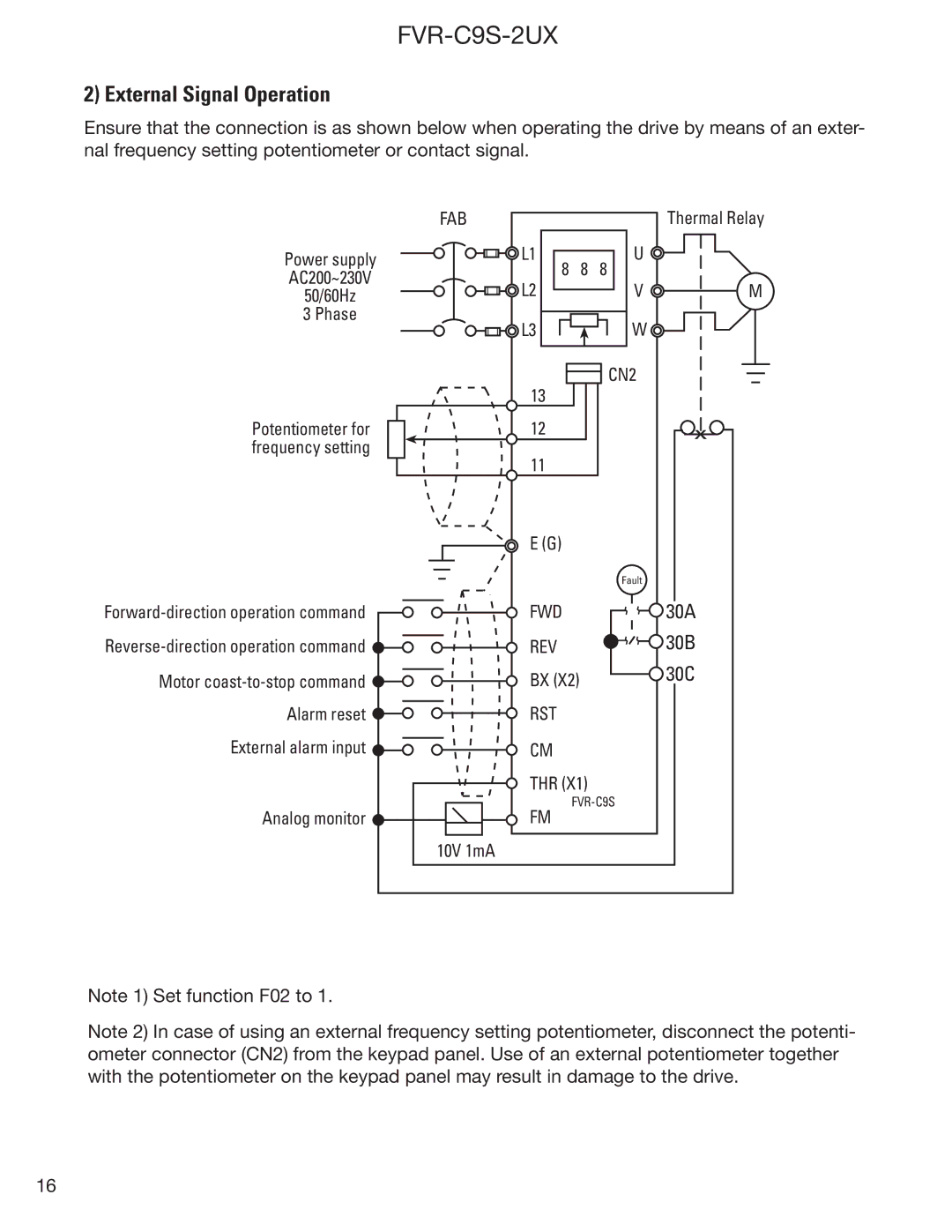

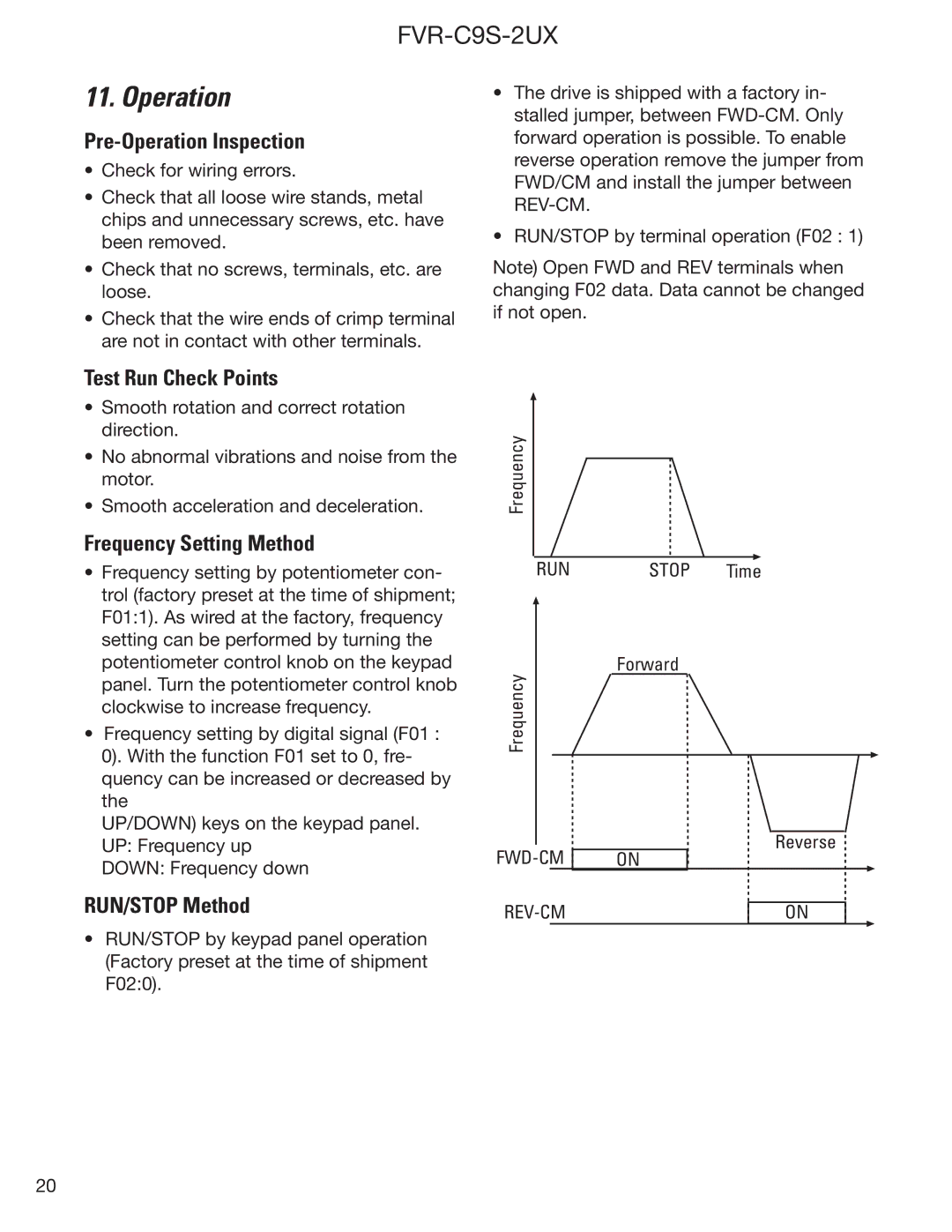

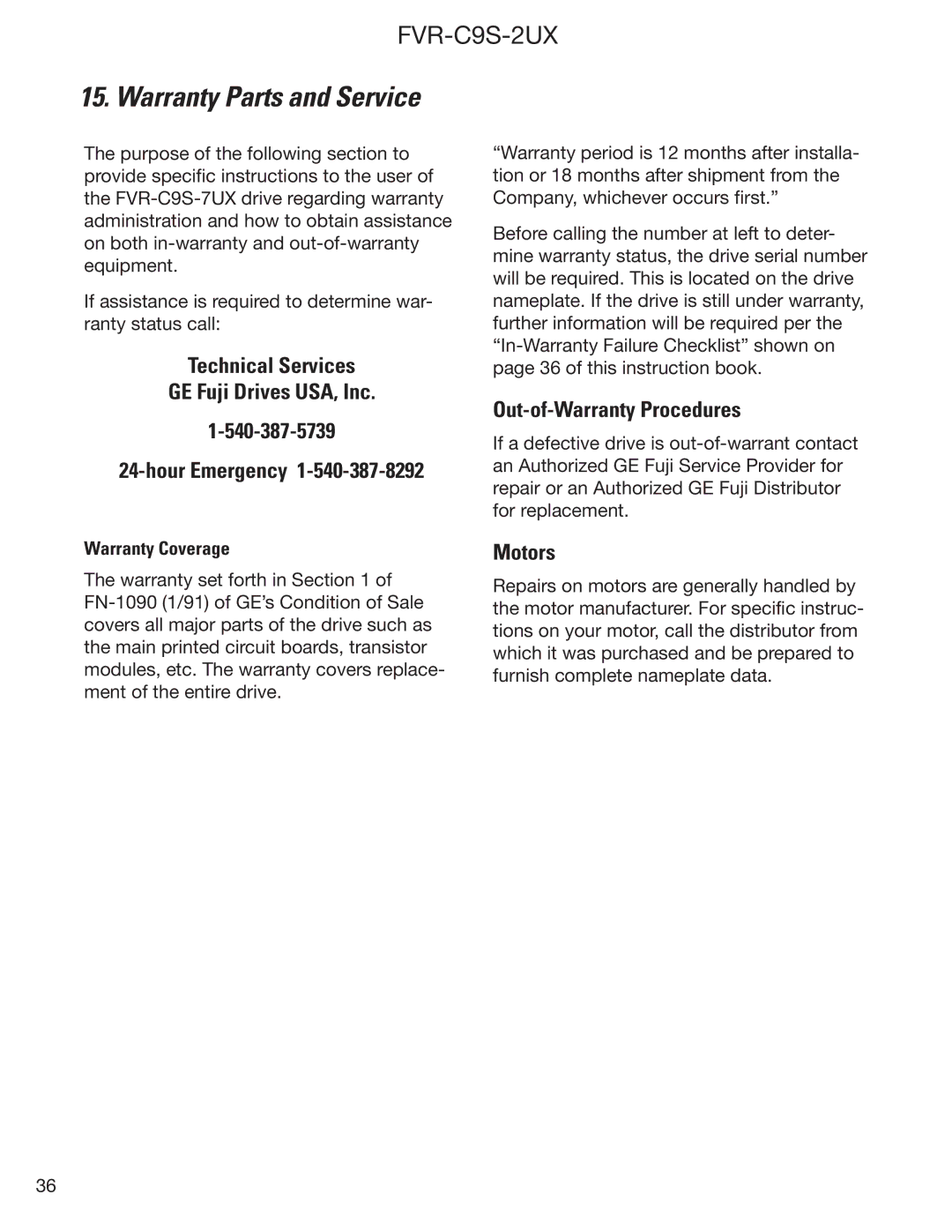

2) External Signal Operation

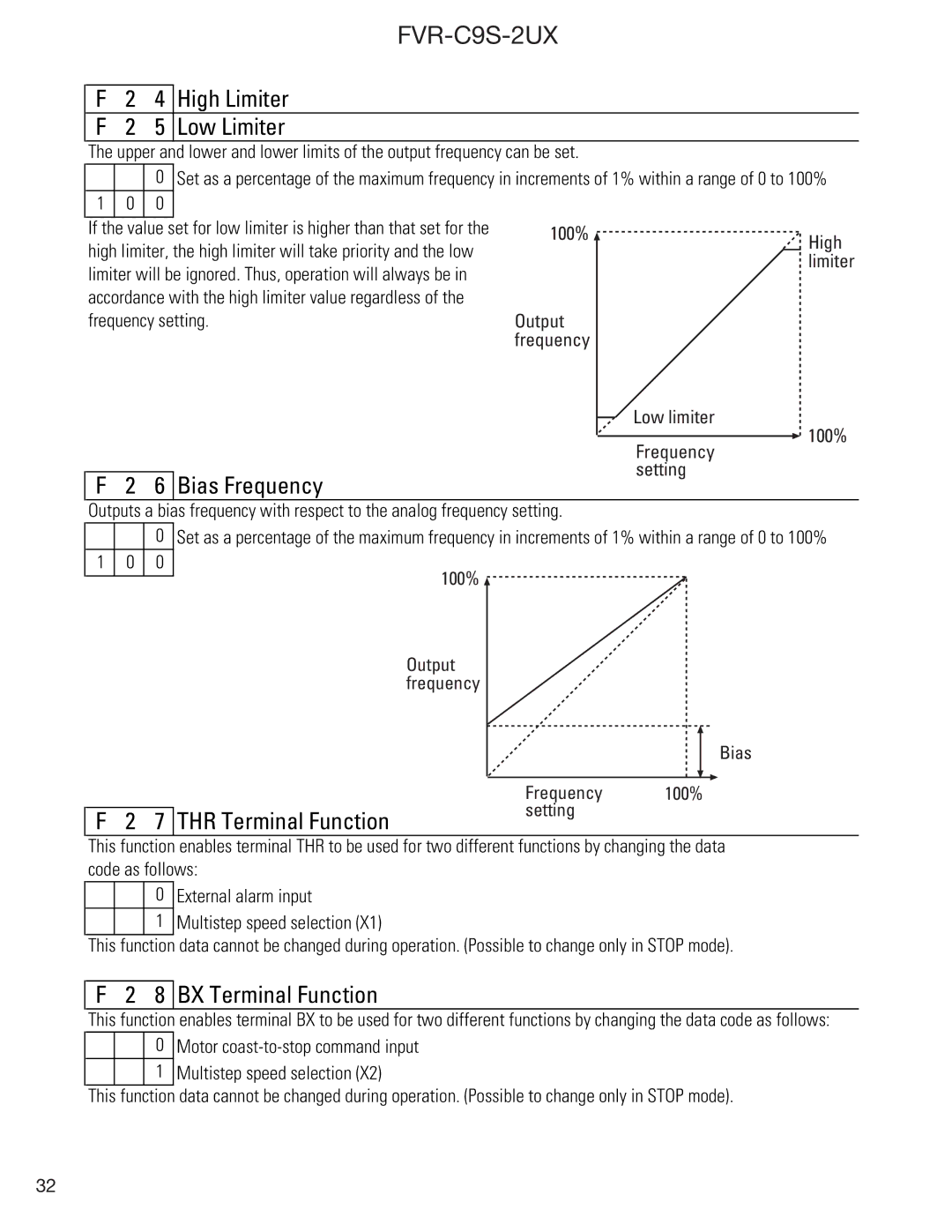

Ensure that the connection is as shown below when operating the drive by means of an exter- nal frequency setting potentiometer or contact signal.

Power supply

AC200~230V

50/60Hz

3 Phase

FAB

![]()

![]()

![]() L1

L1

![]()

![]()

![]() L2

L2

![]()

![]()

![]() L3

L3

8 8 8

Thermal Relay

U![]()

V![]() M W

M W ![]()

Potentiometer for frequency setting

![]()

Motor ![]()

Alarm reset ![]()

External alarm input ![]()

Analog monitor ![]()

Note 1) Set function F02 to 1.

13 | CN2 |

| |

12 | x |

11 |

|

E (G) |

|

| Fault |

FWD | 30A |

REV | 30B |

BX (X2) | 30C |

RST |

|

CM |

|

THR (X1) |

|

| |

FM |

|

10V 1mA

Note 2) In case of using an external frequency setting potentiometer, disconnect the potenti- ometer connector (CN2) from the keypad panel. Use of an external potentiometer together with the potentiometer on the keypad panel may result in damage to the drive.

16