Kirby Morgan 37 & 57

|

| If it is, it must be cleaned out prior to diving. | |

WARNING |

| ||

|

| ||

Use silicone sealant in |

|

| |

a well ventilated area. |

| WARNING | |

Do not breathe the |

| Do not dive the helmet until the sealant | |

fumes from uncured |

| ||

| has had time to cure. Check the direc- | ||

silicone sealant. These |

| ||

| tions on the tube of sealant for curing | ||

fumes are dangerous |

| ||

| time. If the helmet goes into the water | ||

and can cause uncon- |

| ||

| before the sealant has cured it could leak | ||

sciousness. They can |

| ||

| through the side block mounting stud | ||

also cause long term damage to body tis- |

| ||

| hole, screw hole, or air flow hole. This | ||

sue. Read and follow all precautions listed |

| ||

| could lead to drowning. | ||

on the silicone sealant tube and Material |

| ||

|

| ||

Safety Data Sheet. |

|

| |

| WARNING | ||

|

| ||

|

| ||

|

| ||

|

| If silicone sealant is blocking the air flow | |

|

| into the helmet it must be cleaned out. If it | |

|

| is not, the diver may not be able to prop- | |

|

| erly defog the helmet or clear a flooded | |

|

| helmet quickly. In addition, if the demand | |

|

| regulator is not delivering air properly, the | |

|

| diver cannot use the free flow system as | |

|

| a source of breathing air. This could lead | |

DO NOT BLOCK |

| to suffocation. | |

|

| ||

|

| ||

AIR OPENING! |

|

| |

| WARNING | ||

|

| ||

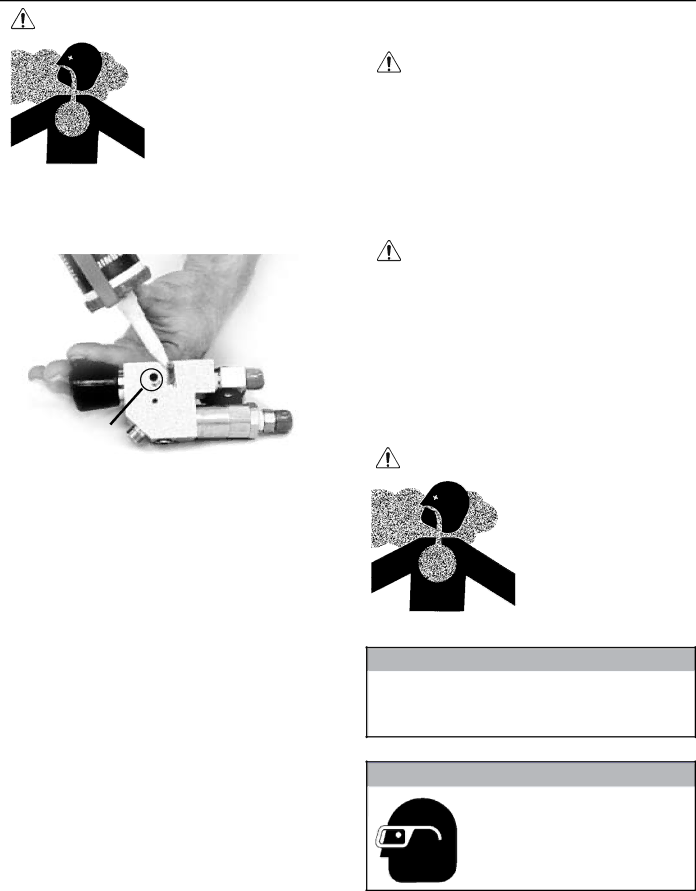

A generous application of silicone sealant must be | |||

Avoid breathing | |||

applied to the side block prior to installation on the | |||

fumes from lacquer | |||

helmet shell. Use only Dow Corning™ RTV 732 Multi | |||

thinner and use in a | |||

Purpose sealant. | |||

well ventilated area. | |||

|

| ||

|

| Breathing fumes | |

3) Slide the flat washer and the lock washer onto the | can lead to nervous | ||

system damage, | |||

stud. Run the stud nut down the stud and tighten to | unconsciousness, | ||

35 inch pounds (4 Newton meters). Do not over- | and death. | ||

tighten! |

| ||

| |||

4)Tighten the screw to the correct torque, 35 inch pounds. Clean off all excess silicone sealant.

5)Place the air train gasket on the base of the air train. The knob on the base of the air train gasket is designed to cover the recessed hole where the bolt that helps maintain the position of the air train is installed. Slip the air train over the stud. Align the air train with the upper edge of the view port opening in the helmet shell.

6)Place the washer on the stud and tighten the nut until the washer lays flush on the air train, 15 inch pounds. Do not overtighten!

7)Test the side block prior to diving to ensure that no silicone sealant is blocking the air flow to the helmet.

![]() WARNING

WARNING

Avoid skin contact with lacquer thinner. Wear rubber gloves. Lacquer thinner can damage the nervous system.

![]() WARNING

WARNING

Avoid eye contact with lac- quer thinner. This chemical is an irritant and may cause tissue damage.

72 | © Copyright |