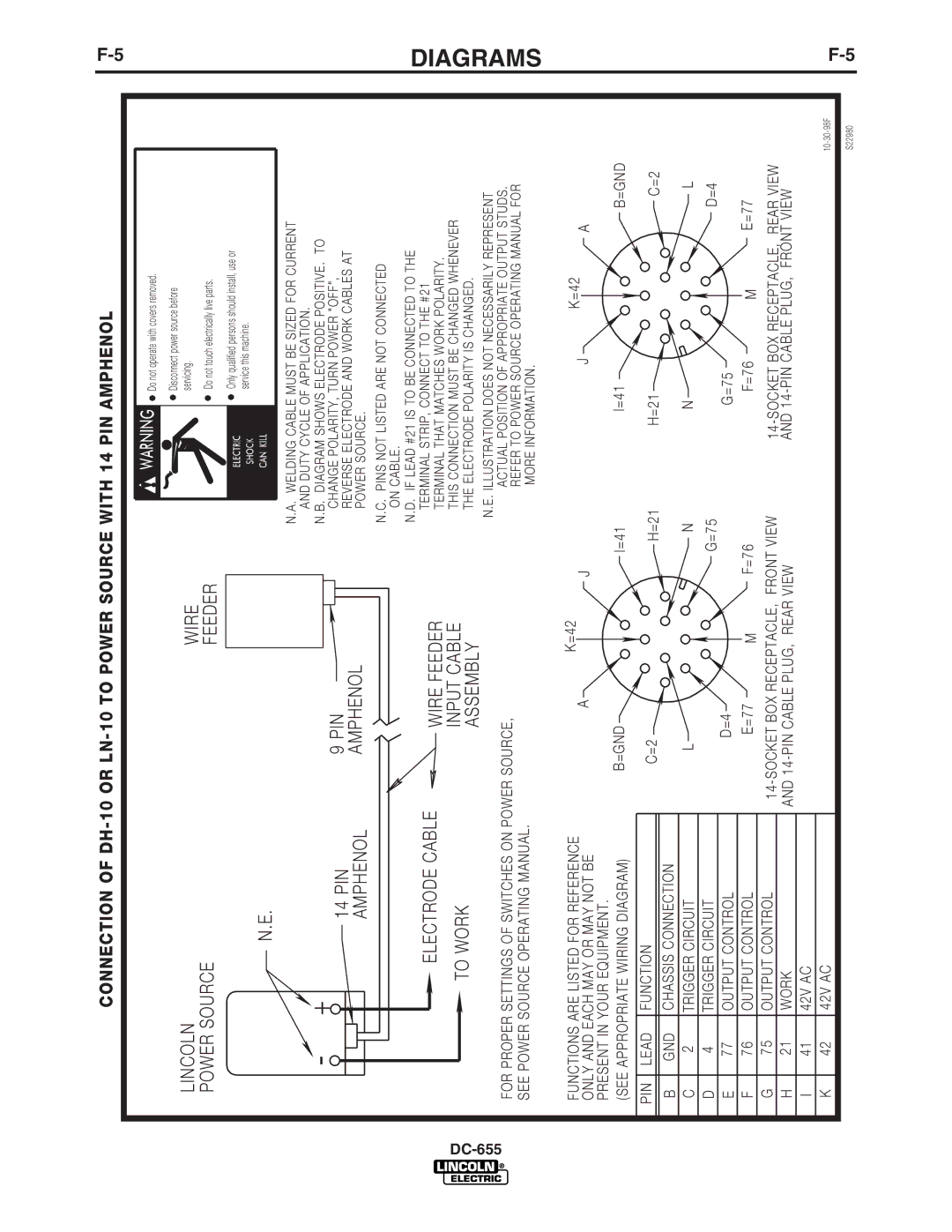

CONNECTION OF

DC-

LINCOLN | WIRE |

POWER SOURCE | FEEDER |

| N.E. |

|

- | + | 9 PIN |

| 14 PIN | |

| AMPHENOL | AMPHENOL |

| ELECTRODE CABLE | WIRE FEEDER |

| TO WORK | INPUT CABLE |

| ASSEMBLY | |

|

|

![]()

![]()

![]()

![]()

![]()

![]() Do not operate with covers removed.

Do not operate with covers removed.

![]() Disconnect power source before servicing.

Disconnect power source before servicing.

Do not touch electrically live parts.

![]()

![]() Only qualified persons should install, use or

Only qualified persons should install, use or ![]()

![]()

![]() service this machine.

service this machine.

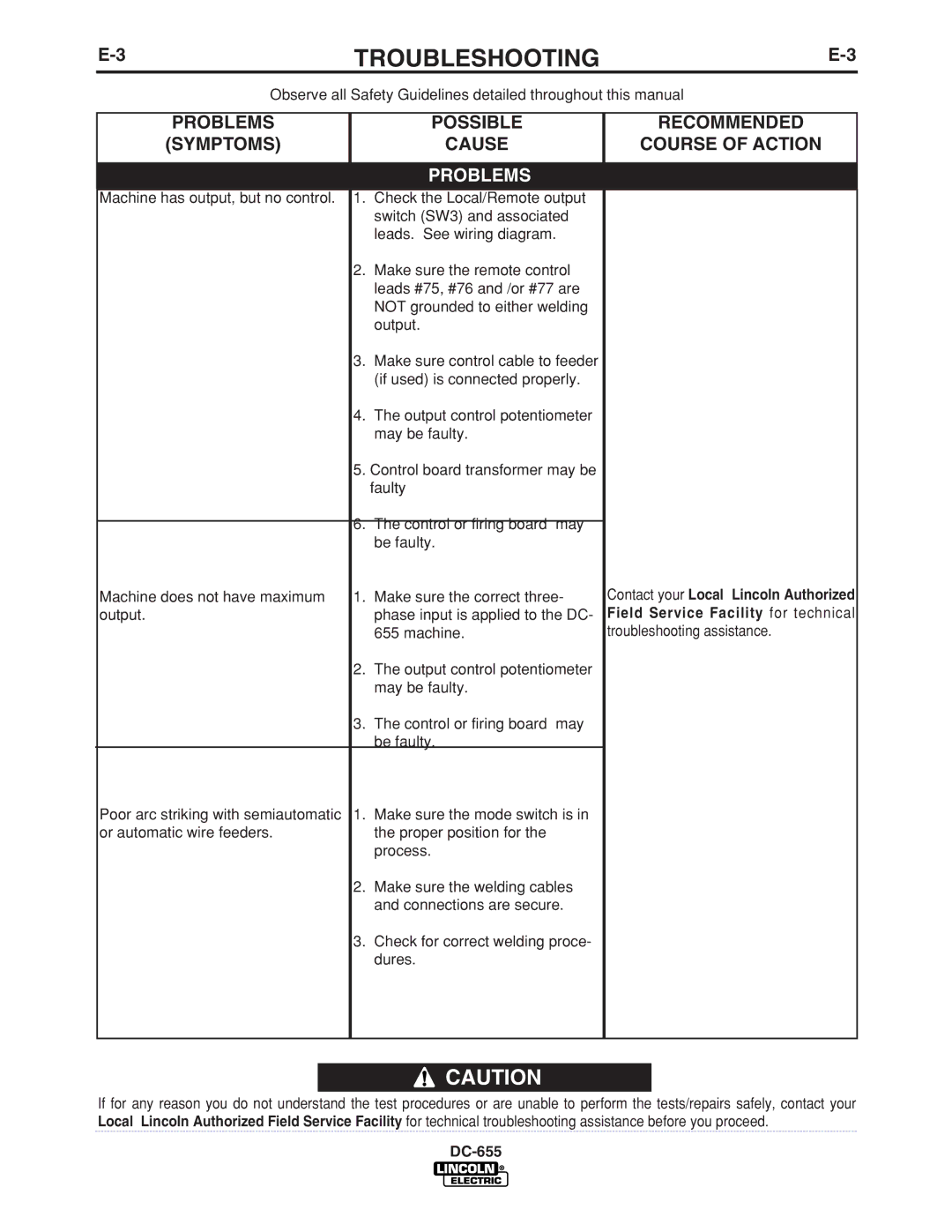

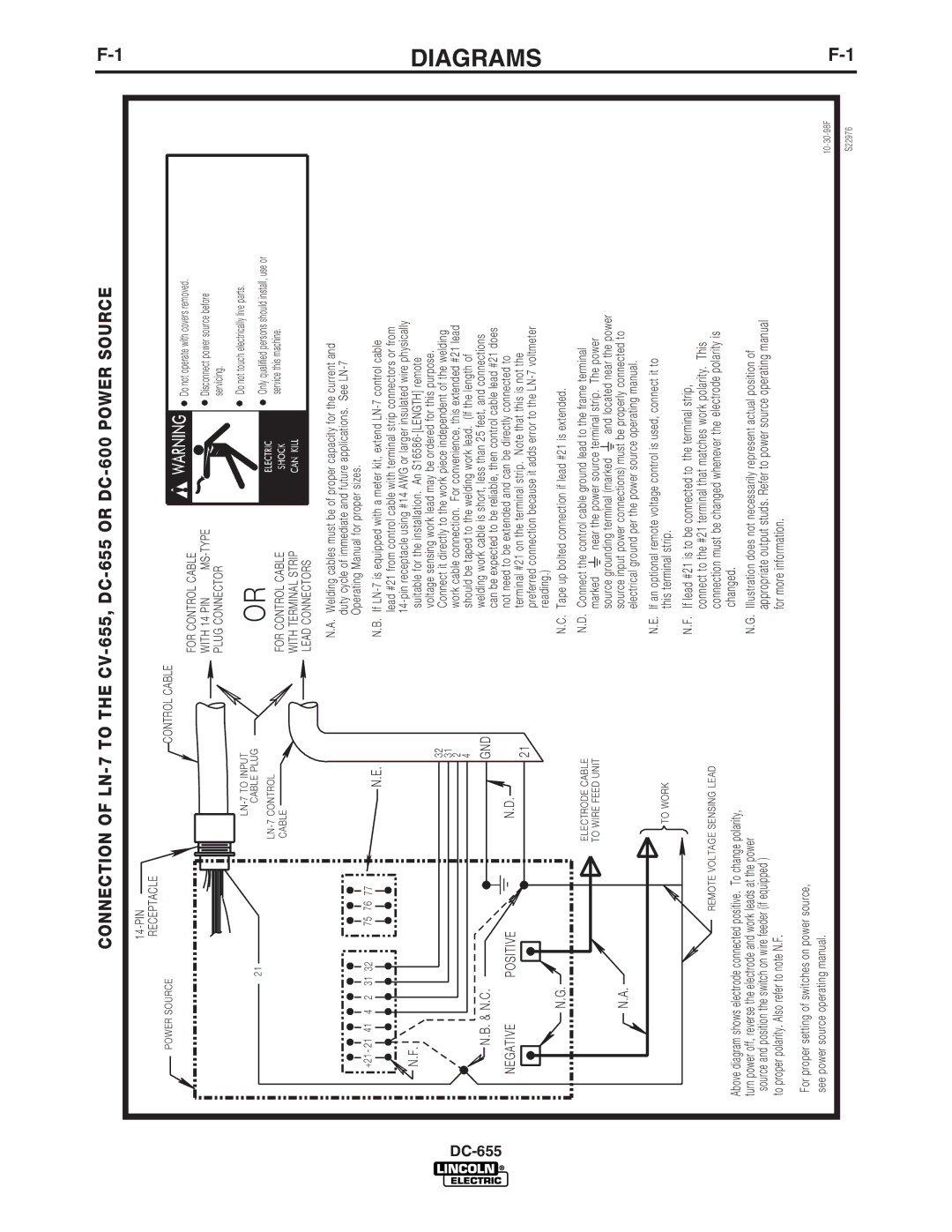

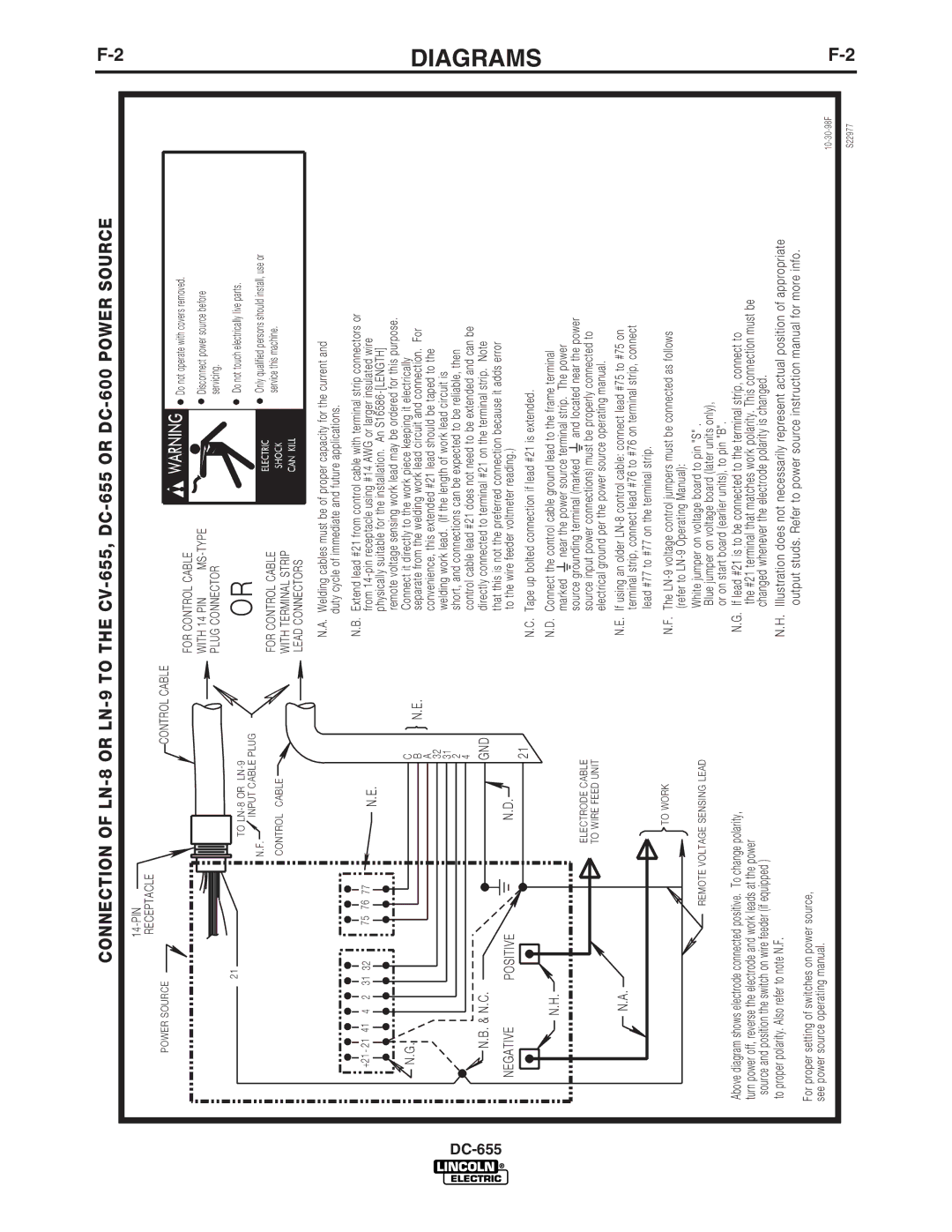

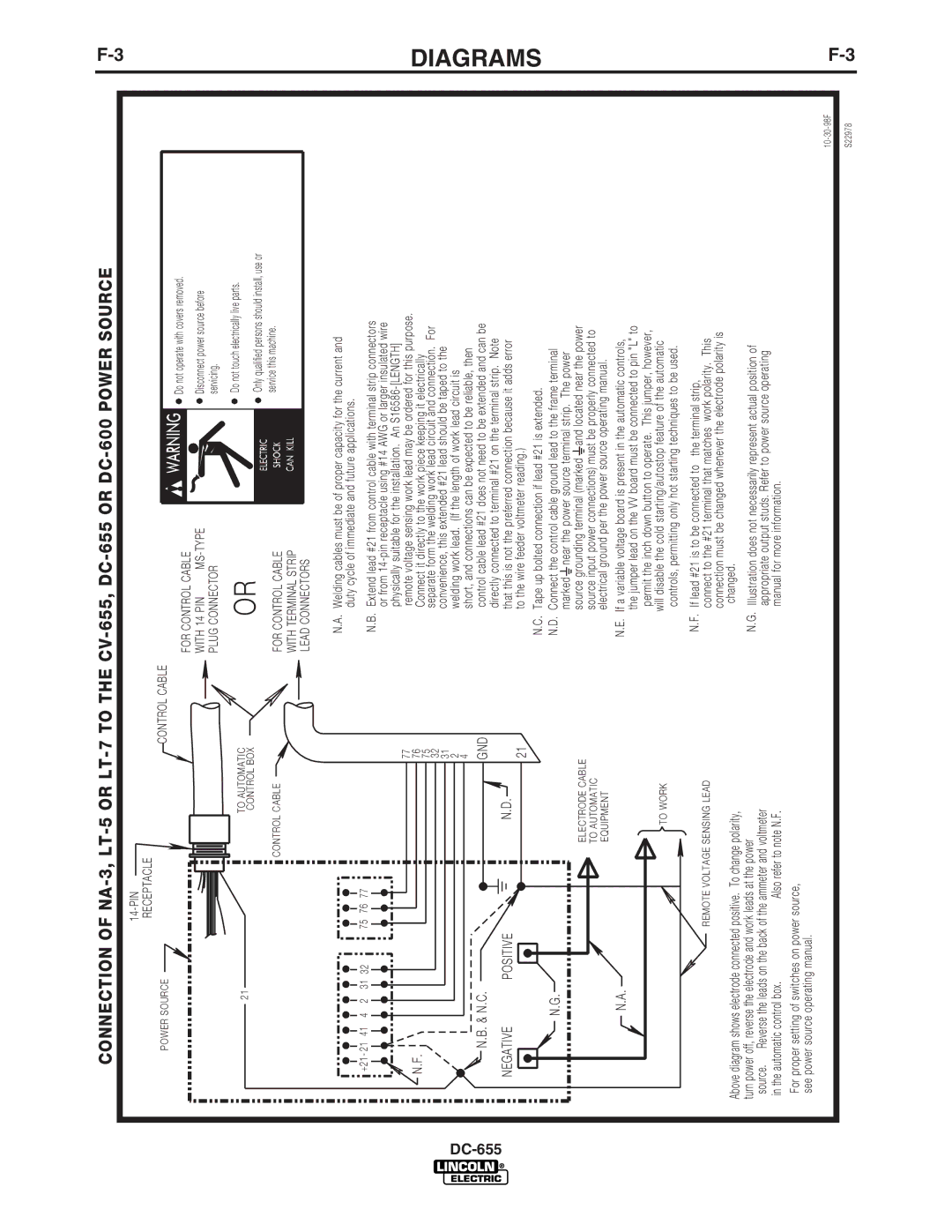

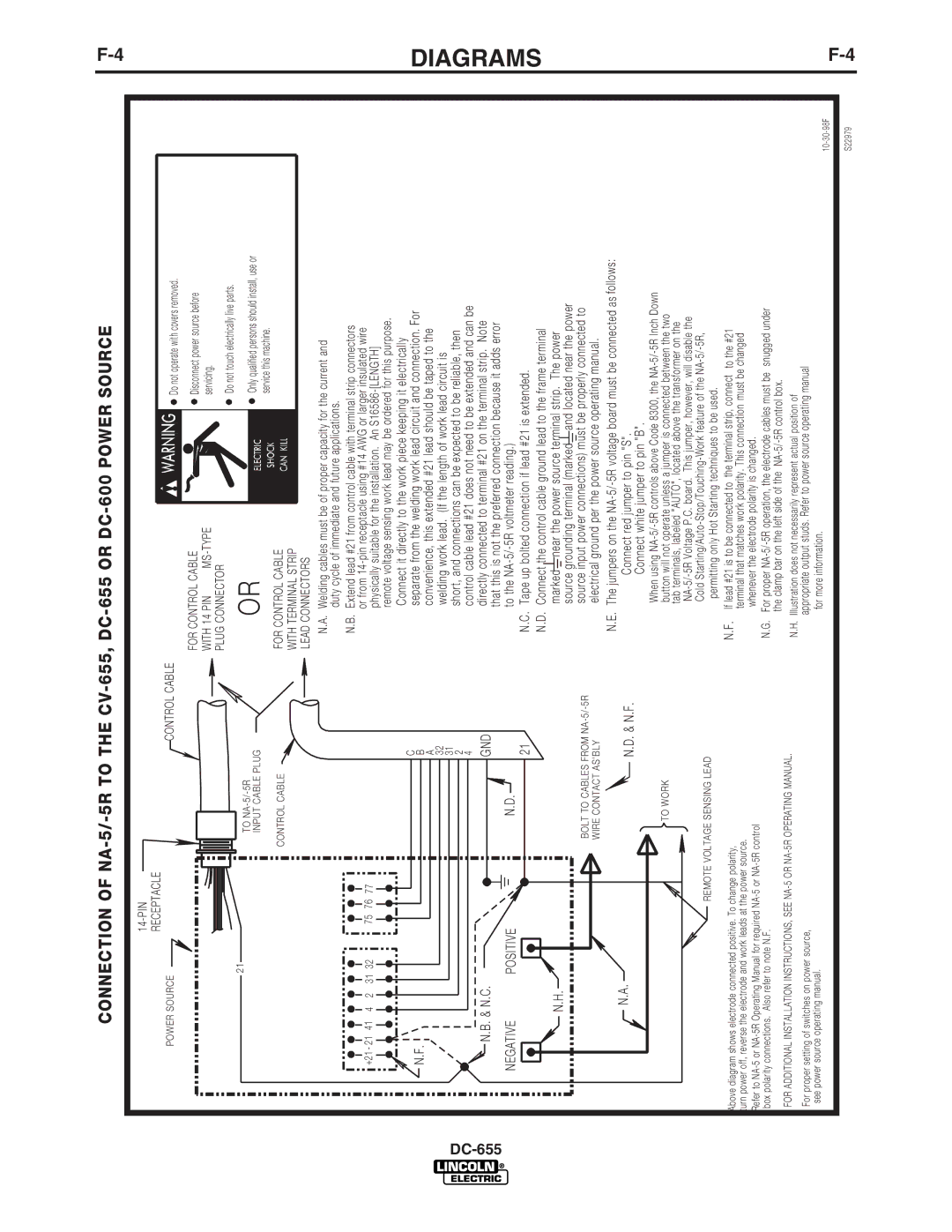

N.A. WELDING CABLE MUST BE SIZED FOR CURRENT AND DUTY CYCLE OF APPLICATION.

N.B. DIAGRAM SHOWS ELECTRODE POSITIVE. TO CHANGE POLARITY, TURN POWER "OFF", REVERSE ELECTRODE AND WORK CABLES AT POWER SOURCE.

N.C. PINS NOT LISTED ARE NOT CONNECTED ON CABLE.

N.D. IF LEAD #21 IS TO BE CONNECTED TO THE TERMINAL STRIP, CONNECT TO THE #21 TERMINAL THAT MATCHES WORK POLARITY.

THIS CONNECTION MUST BE CHANGED WHENEVER THE ELECTRODE POLARITY IS CHANGED.

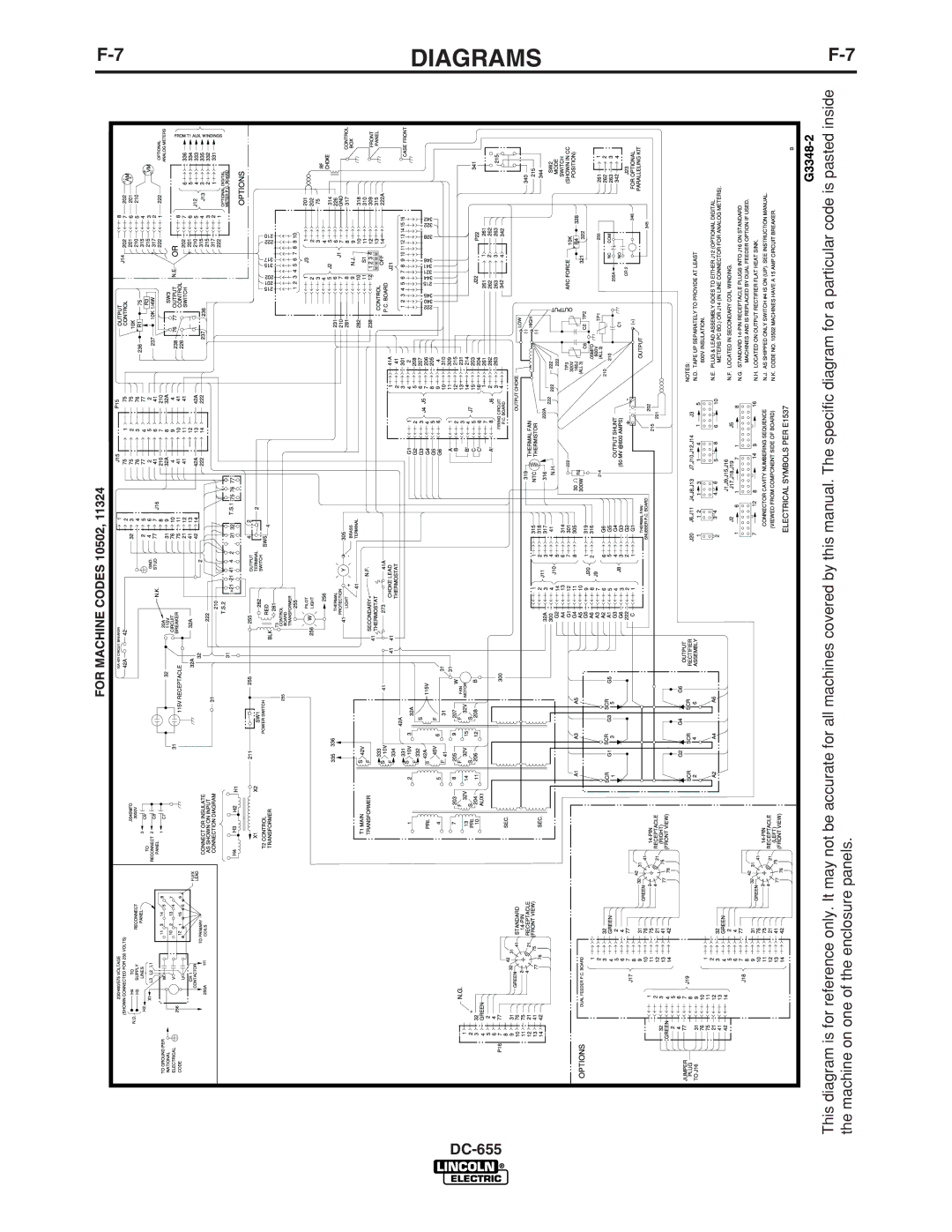

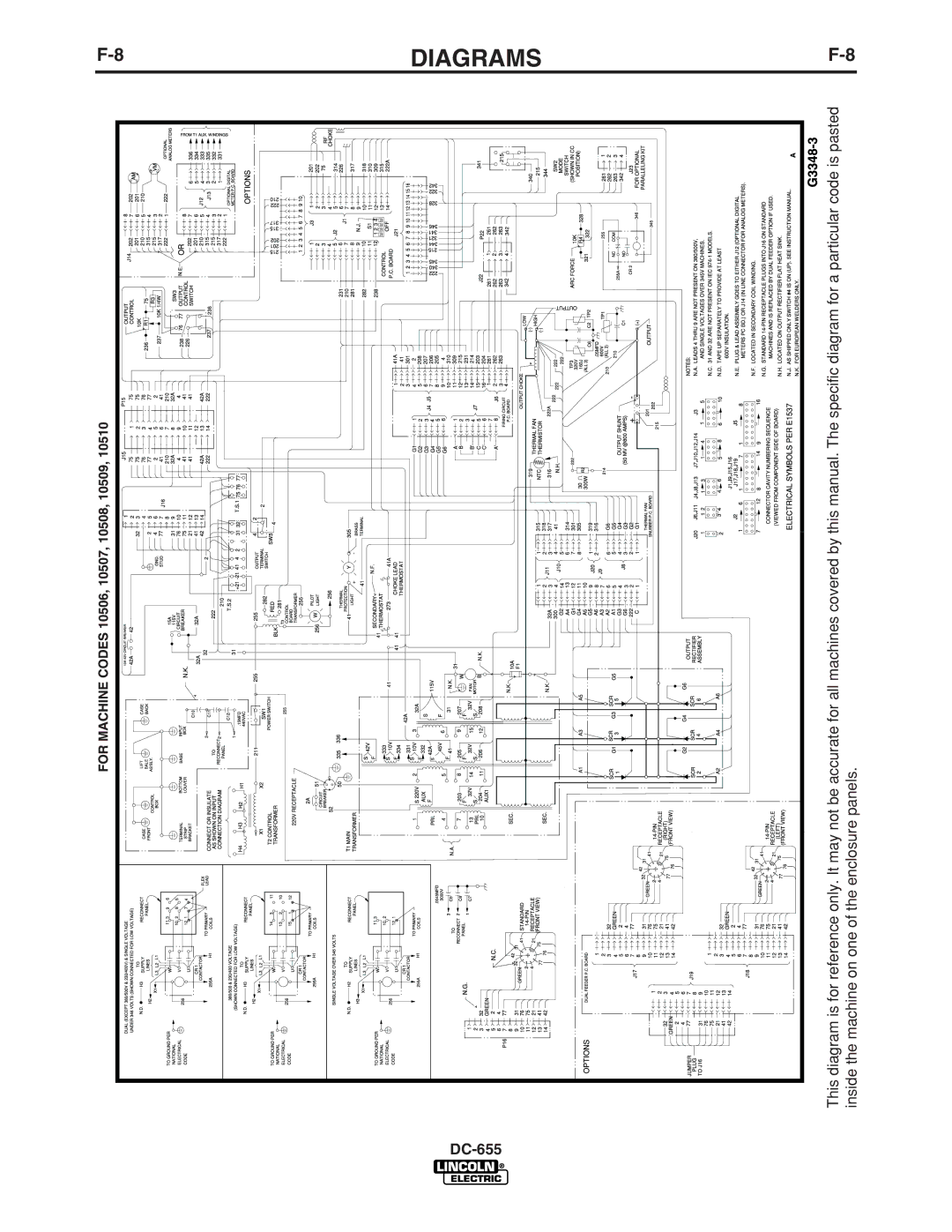

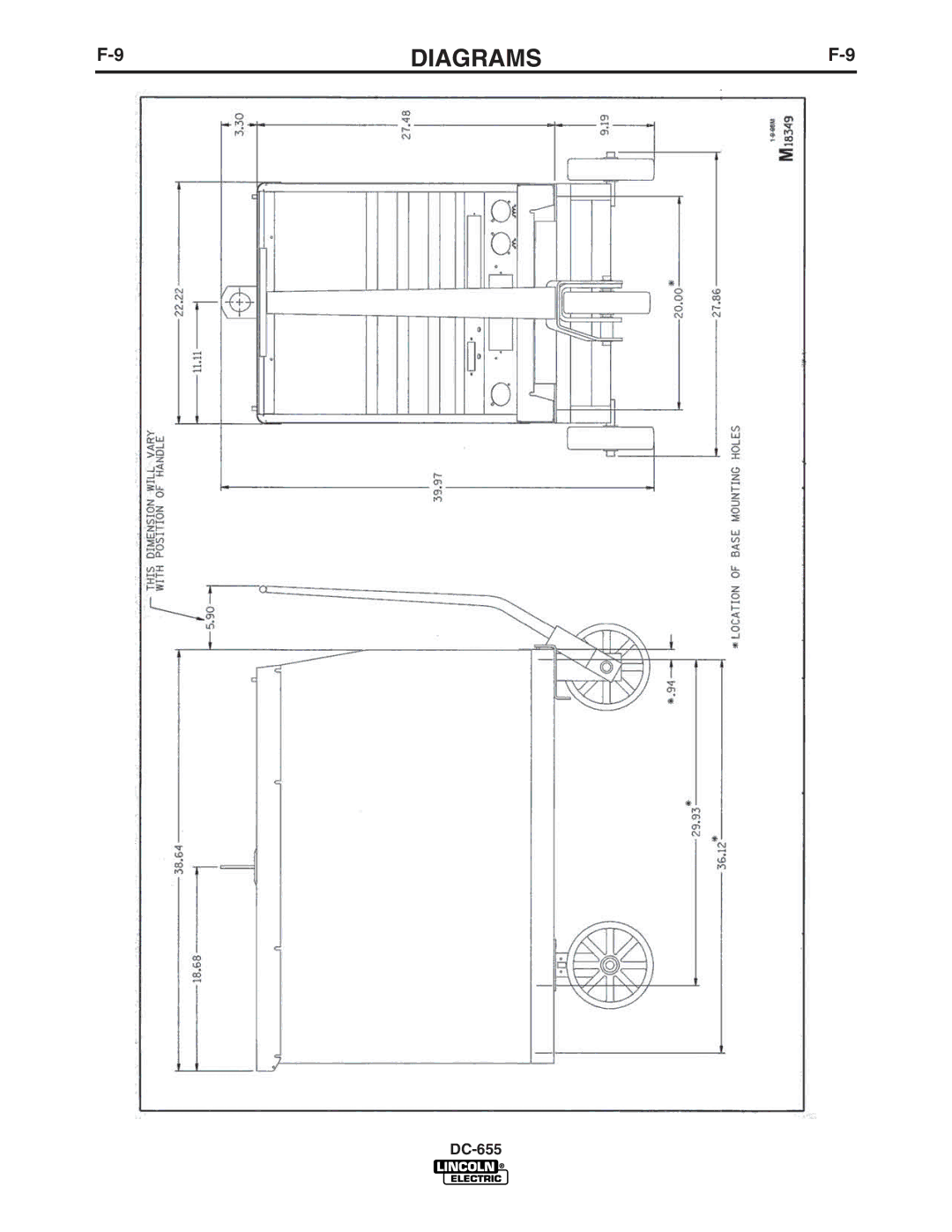

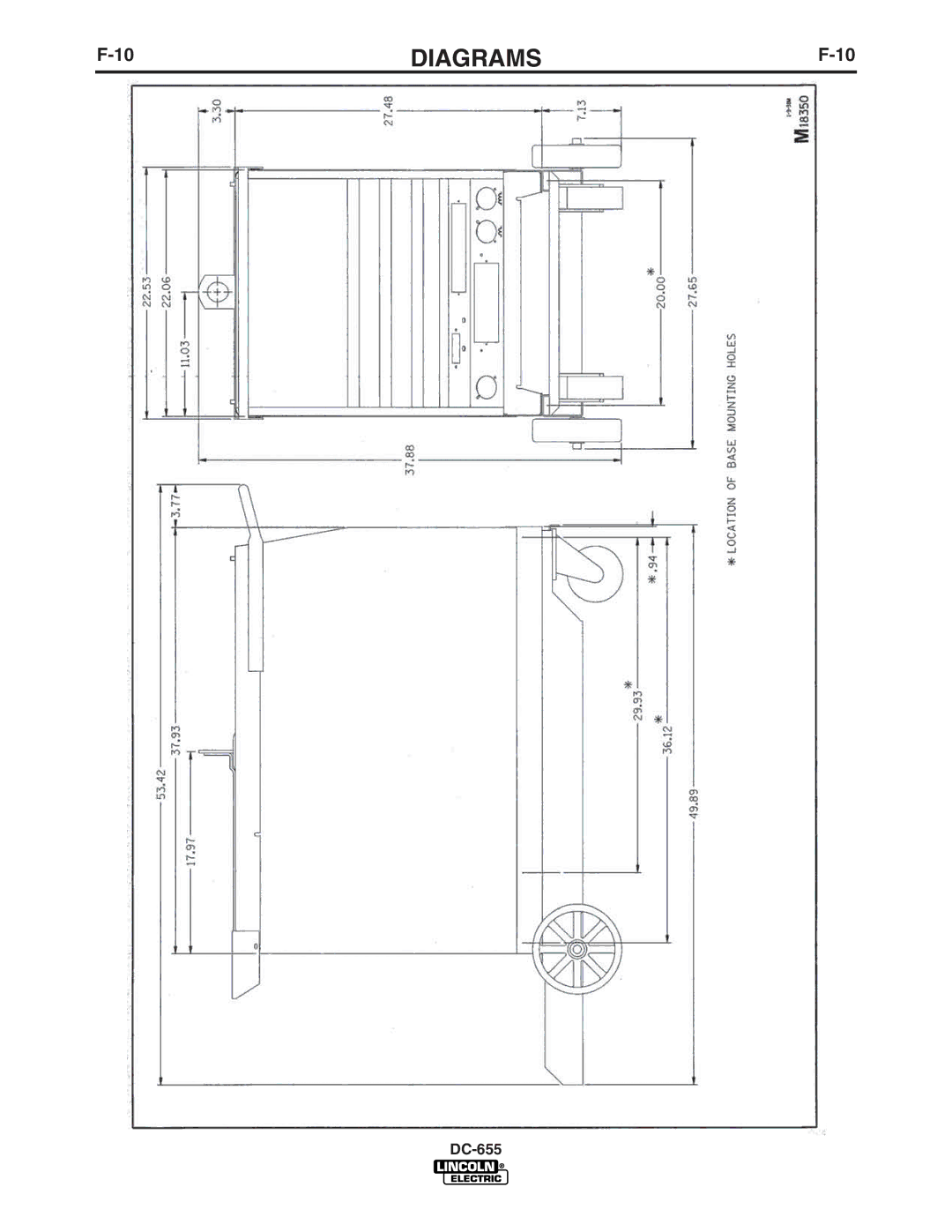

DIAGRAMS

655

|

|

|

|

| N.E. ILLUSTRATION DOES NOT NECESSARILY REPRESENT | |||

FOR PROPER SETTINGS OF SWITCHES ON POWER SOURCE, |

|

| ACTUAL POSITION OF APPROPRIATE OUTPUT STUDS. | |||||

SEE POWER SOURCE OPERATING MANUAL. |

|

|

| REFER TO POWER SOURCE OPERATING MANUAL FOR | ||||

|

|

| MORE INFORMATION. |

|

| |||

|

|

|

|

|

|

|

| |

FUNCTIONS ARE LISTED FOR REFERENCE | K=42 |

| J | K=42 |

| |||

ONLY AND EACH MAY OR MAY NOT BE | A |

| J |

| A | |||

PRESENT IN YOUR EQUIPMENT. | B=GND |

| I=41 | I=41 |

|

| ||

(SEE APPROPRIATE WIRING DIAGRAM) |

|

| B=GND | |||||

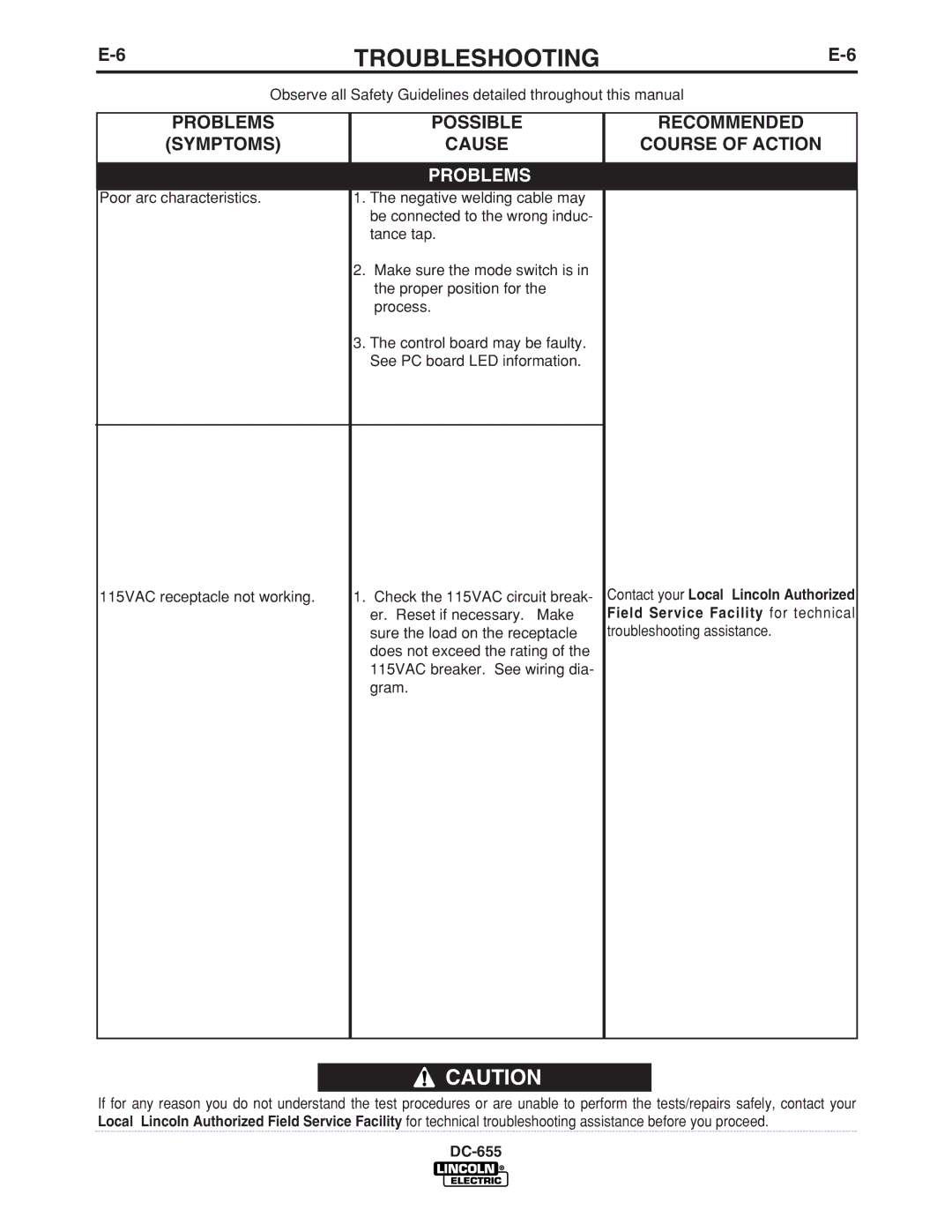

PIN | LEAD | FUNCTION | C=2 |

| H=21 | H=21 |

| C=2 |

B | GND | CHASSIS CONNECTION |

|

| ||||

|

|

|

|

|

| |||

C | 2 | TRIGGER CIRCUIT | L |

| N | N |

| L |

D | 4 | TRIGGER CIRCUIT | D=4 |

| G=75 |

|

| D=4 |

E | 77 | OUTPUT CONTROL |

|

| G=75 |

|

| |

F | 76 | OUTPUT CONTROL | E=77 | M | F=76 | F=76 | M | E=77 |

G | 75 | OUTPUT CONTROL | FRONT VIEW | |||||

| 21 | WORK | ||||||

H | AND | REAR VIEW | AND | FRONT VIEW | ||||

I | 41 | 42V AC |

|

|

|

|

|

|

K | 42 | 42V AC |

|

|

|

|

| |

|

|

|

|

|

|

|

| S22980 |