TROUBLESHOOTING | ||

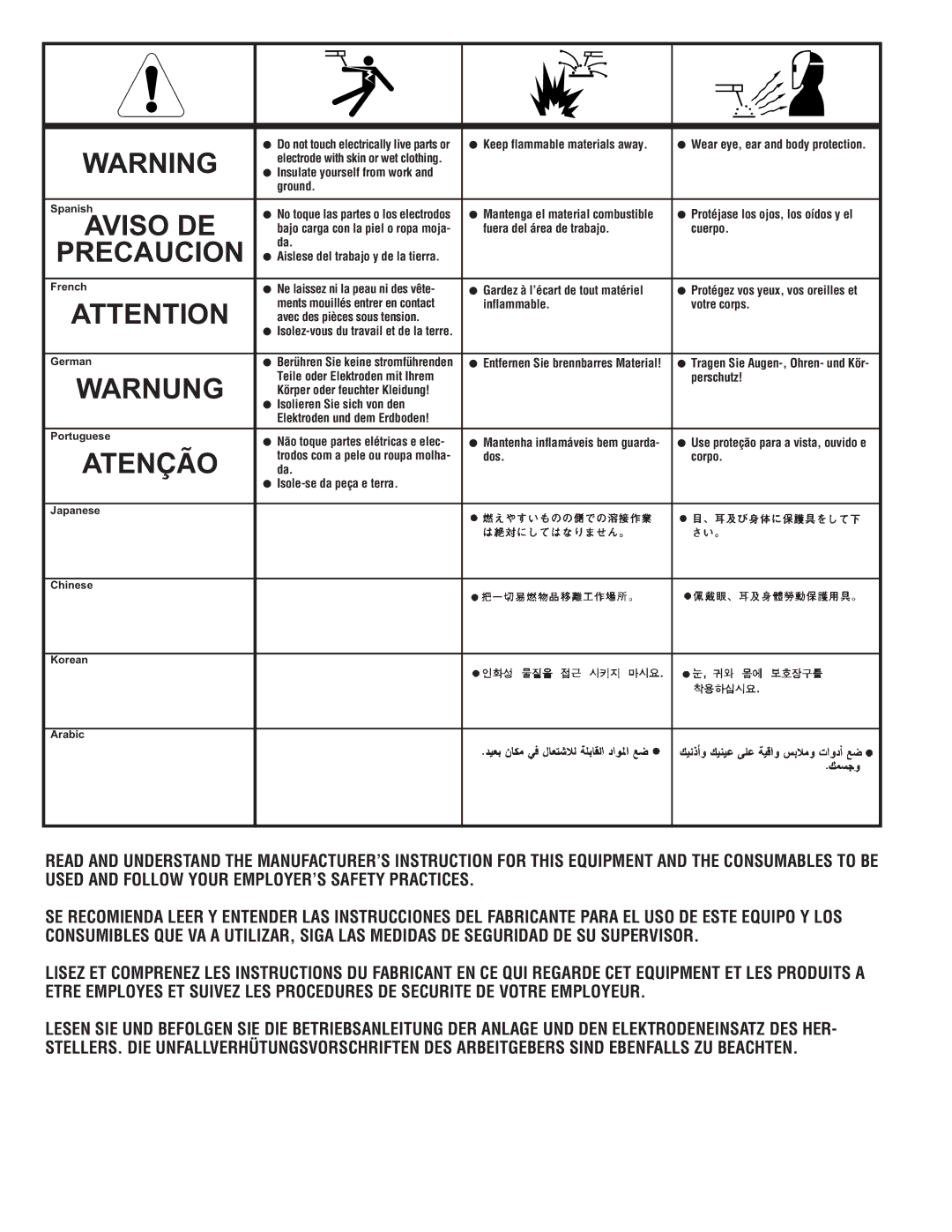

| Observe all Safety Guidelines detailed throughout this manual |

|

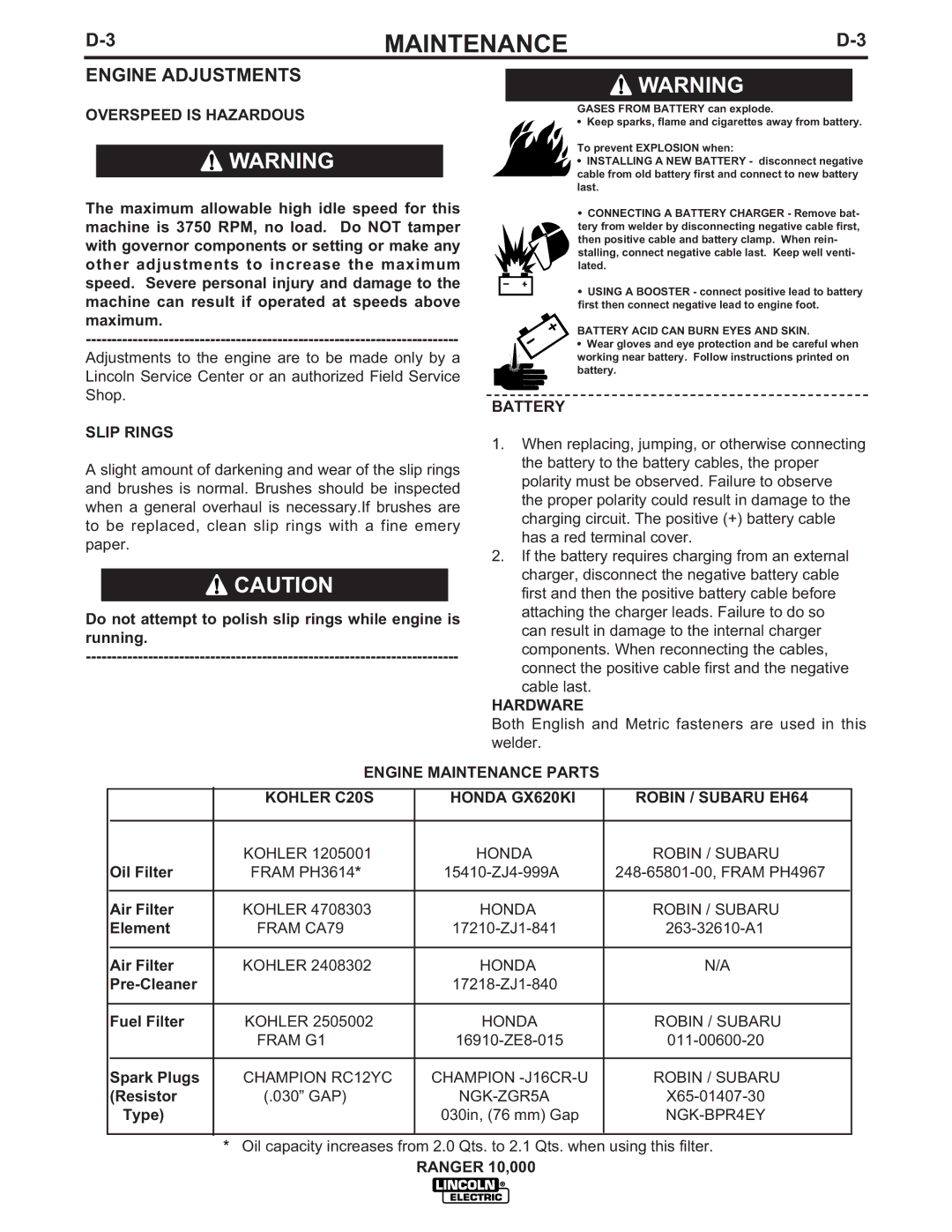

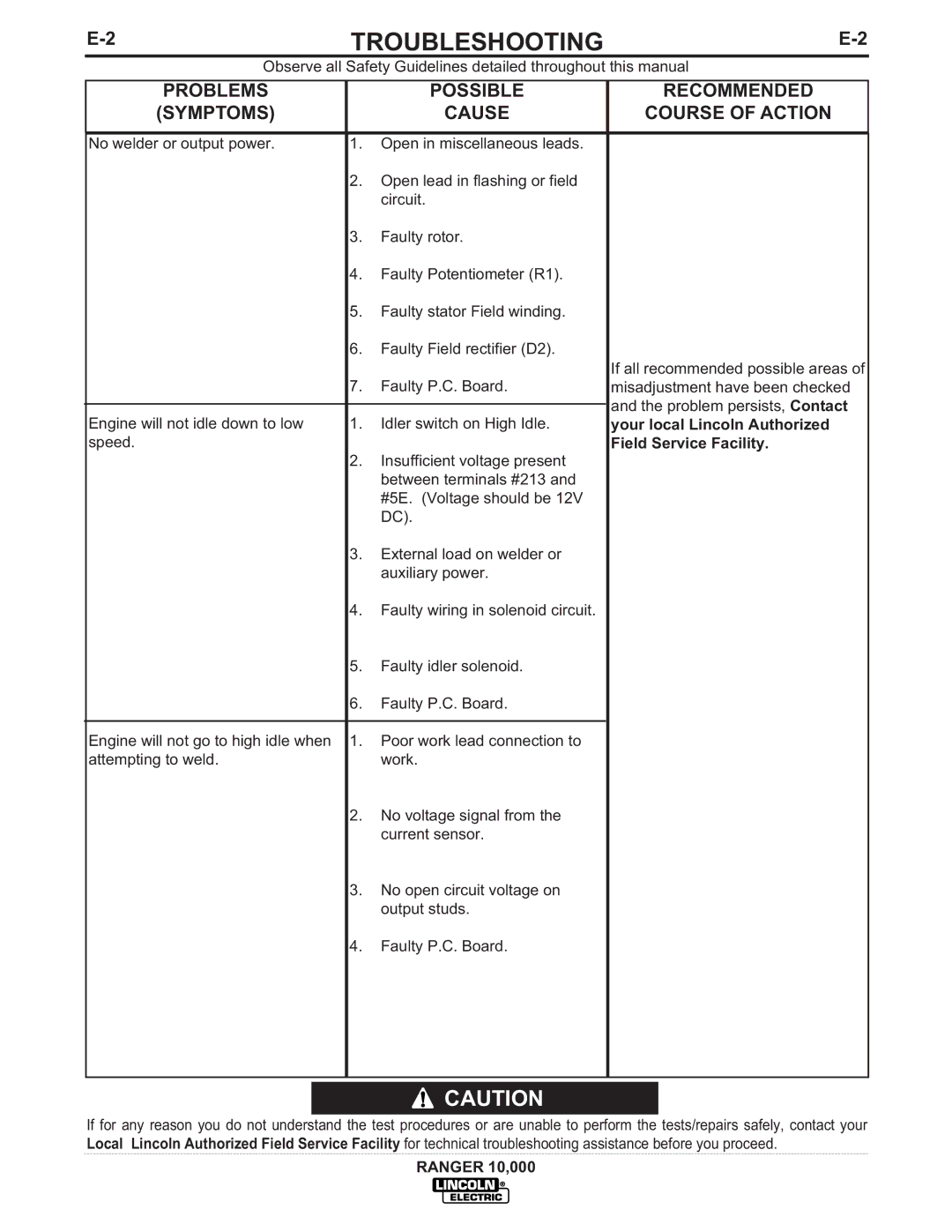

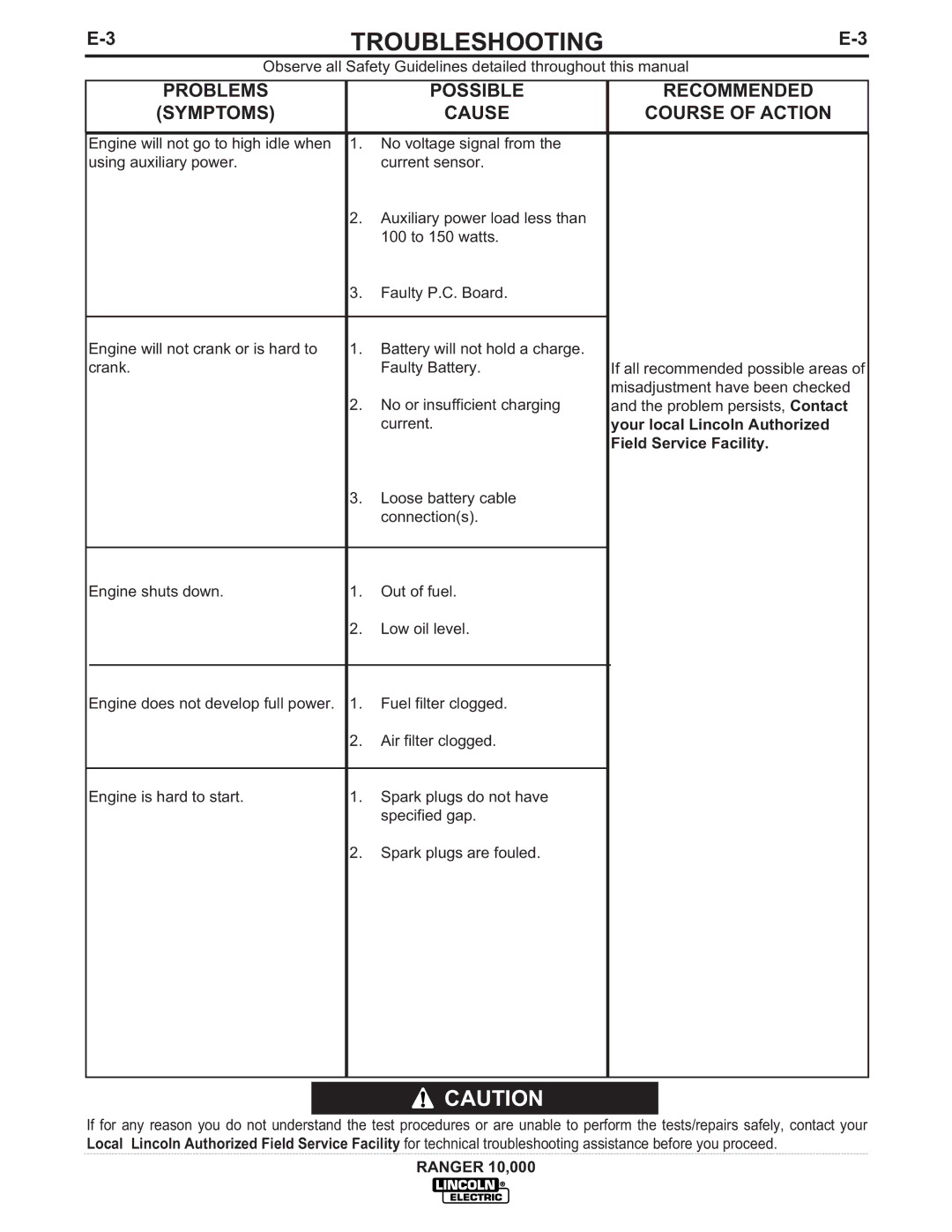

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

No welder or output power. | 1. | Open in miscellaneous leads. |

| 2. | Open lead in flashing or field |

|

| circuit. |

| 3. | Faulty rotor. |

| 4. | Faulty Potentiometer (R1). |

| 5. | Faulty stator Field winding. |

| 6. | Faulty Field rectifier (D2). |

| 7. | Faulty P.C. Board. |

|

|

|

Engine will not idle down to low | 1. | Idler switch on High Idle. |

speed. | 2. | Insufficient voltage present |

| ||

|

| between terminals #213 and |

|

| #5E. (Voltage should be 12V |

|

| DC). |

| 3. | External load on welder or |

|

| auxiliary power. |

| 4. | Faulty wiring in solenoid circuit. |

| 5. | Faulty idler solenoid. |

| 6. | Faulty P.C. Board. |

|

|

|

Engine will not go to high idle when | 1. | Poor work lead connection to |

attempting to weld. |

| work. |

| 2. | No voltage signal from the |

|

| current sensor. |

| 3. | No open circuit voltage on |

|

| output studs. |

If all recommended possible areas of misadjustment have been checked and the problem persists, Contact your local Lincoln Authorized Field Service Facility.

4.Faulty P.C. Board.

![]()

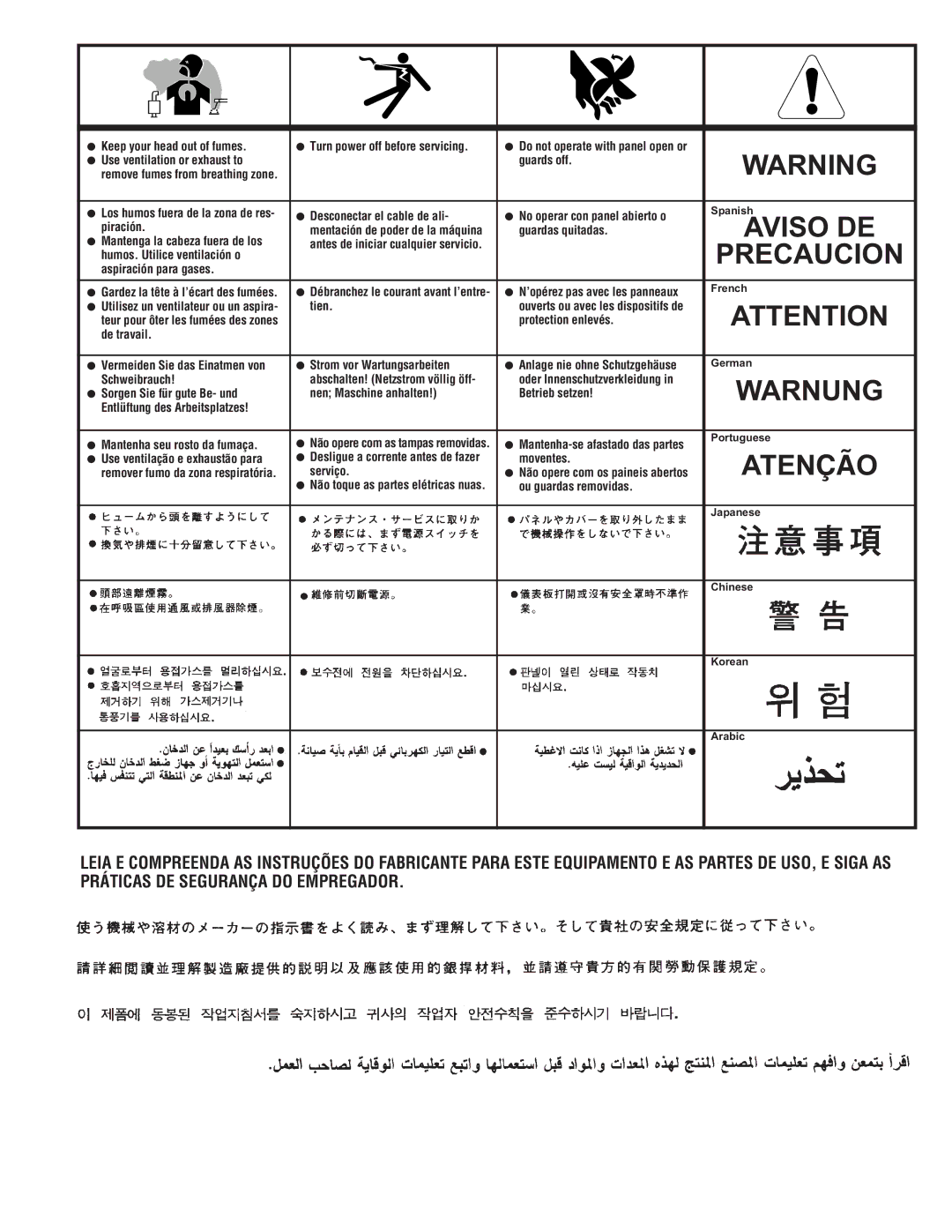

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

RANGER 10,000