1.Insert the tap into the chuck. TIGHTEN THE CHUCK SO THAT THE CHUCK JAWS GRIP THE ROUND PORTION OF THE SHANK AND NOT THE FLATS OF THE TAP.

2.For tapping existing holes, align the tap so it is centered with the hole and reenergize the base.

3.Lubricate the tap and hole and lower the tap onto the work surface. Turn the drill speed control to the slowest setting and push the “Drill Fwd” button (“Drill Rev” for the left hand threads) to start the drill motor. Adjust the speed control knob so the tap turns slowly and smoothly into the hole.

4.When using smaller taps, reverse the motor as soon as the tap breaks through the hole. With large taps, reverse the motor as soon as the first full thread is exposed, the motor does not have to be stopped before changing directions.

5.Reverse the motor to slowly withdraw the tap from the hole. Maintain light pressure on the handle to compensate for the weight of the drill motor on the tap. As soon as the tap comes out of the hole, raise the motor and tap clear of the workpiece.

NOTE: Only the low speed shift setting on the

Using Twist Drills

When preparing to drill, align the bit with the area to be drilled. When proper align- ment is established, energize the magnet and start the drill motor. A pilot hole is recommended for drilling holes larger than 1/2" in diameter.

When drilling, apply only enough force to produce a curled chip. Applying too little force will result in small broken chips and increased drilling time. Applying too much force will cause overheating of the bit result- ing in short bit life. Overheating of the bit can be noticed when drill bit and chips turn brown or blue. Excessive force can cause the drill to slow down to a point where drilling time will increase. The use of cutting lubricants will reduce drilling heat and increase drill bit life.

Using MILWAUKEE STEEL HAWG™

CUTTERS

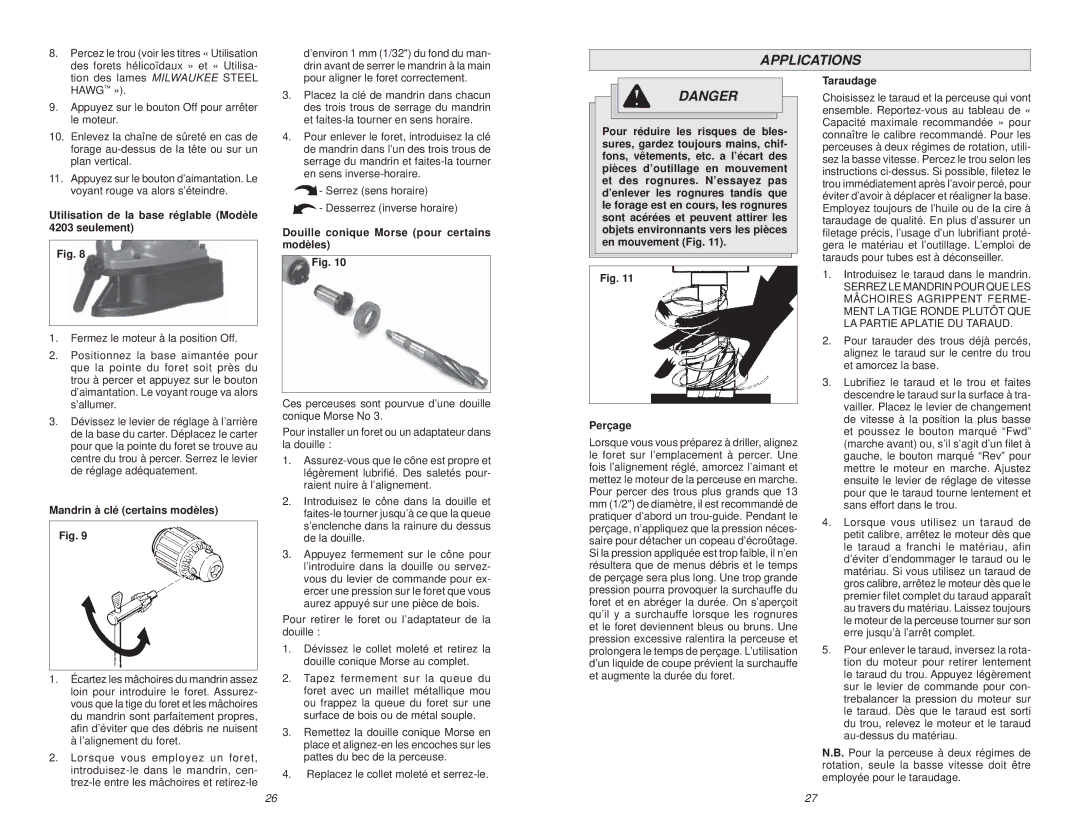

MILWAUKEE STEEL HAWG™ CUTTERS cut an annular ring around the edge of the hole leaving the center “slug” intact. This greatly reduces the time, power and drilling force required. The carbide teeth also leave a finished hole that does not require reaming. These cutters are designed for use with an electromagnetic or industrial drill press.

•Do not use these cutters in hand held tools.

•Center pin is spring loaded. Provide protection from ejected slug for people and property below drilling area.

•Do not remove cutter from arbor unless slug is removed. Slug may be ejected unexpectedly.

•Keep pump bottle and hose away from moving parts.

•Use pliers to remove chips from bit and arbor only after motor has stopped.

•Avoid contact with the carbide tips.

•Periodically inspect the carbide tips for loose or cracked tips. DO NOT USE carbide tips with cracked or loose tips.

WARNING

•These bits require the use of HAWG WASH™ cutting fluid for extended life. Do not use cutting fluid in an overhead or any other position that allows cutting fluid to enter motor or switch enclosure.

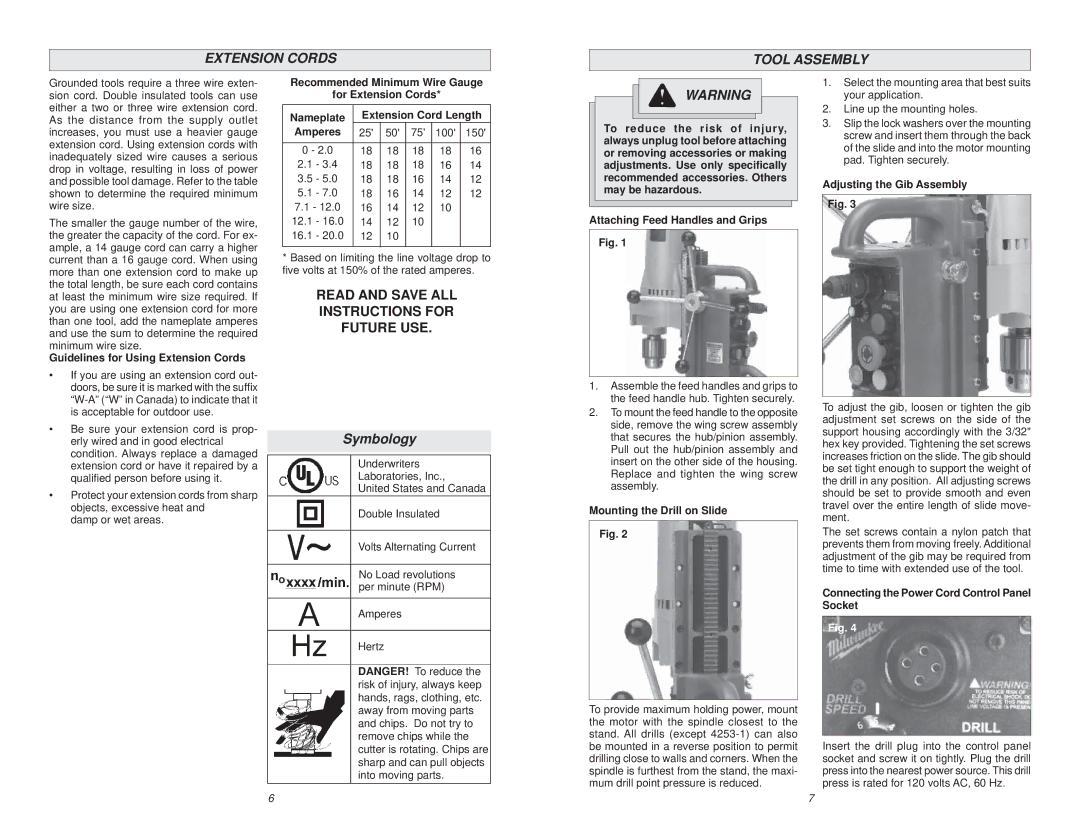

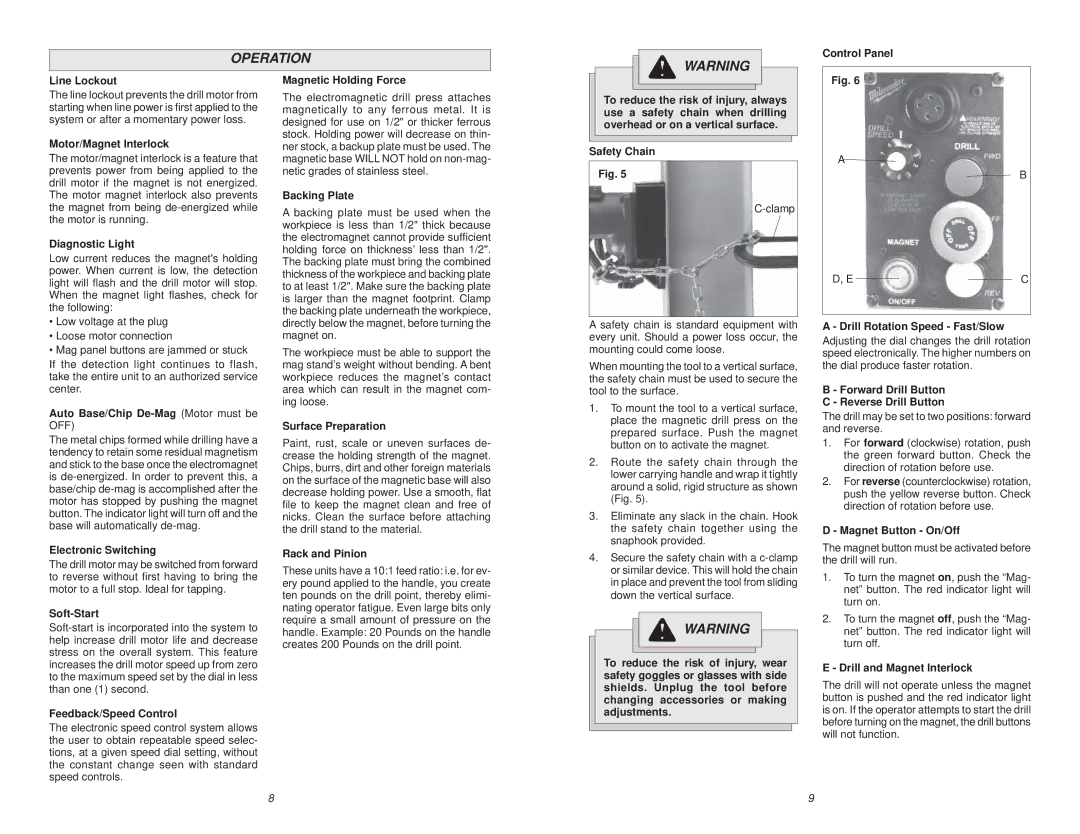

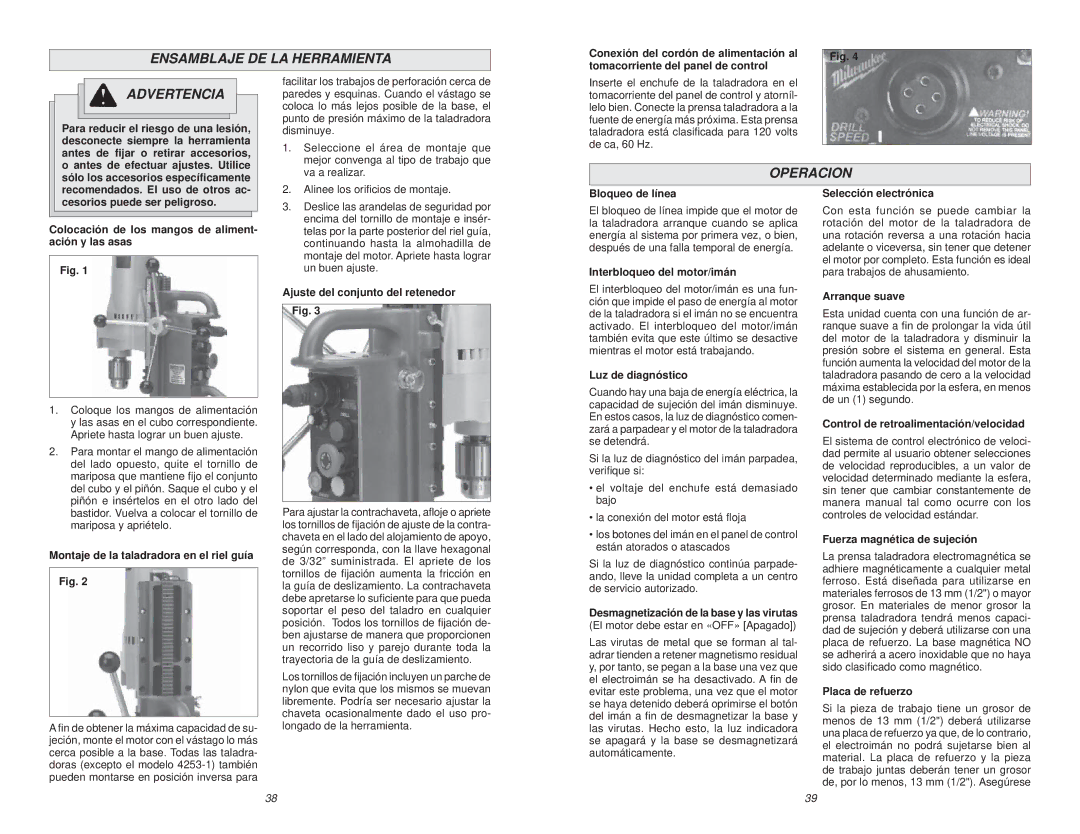

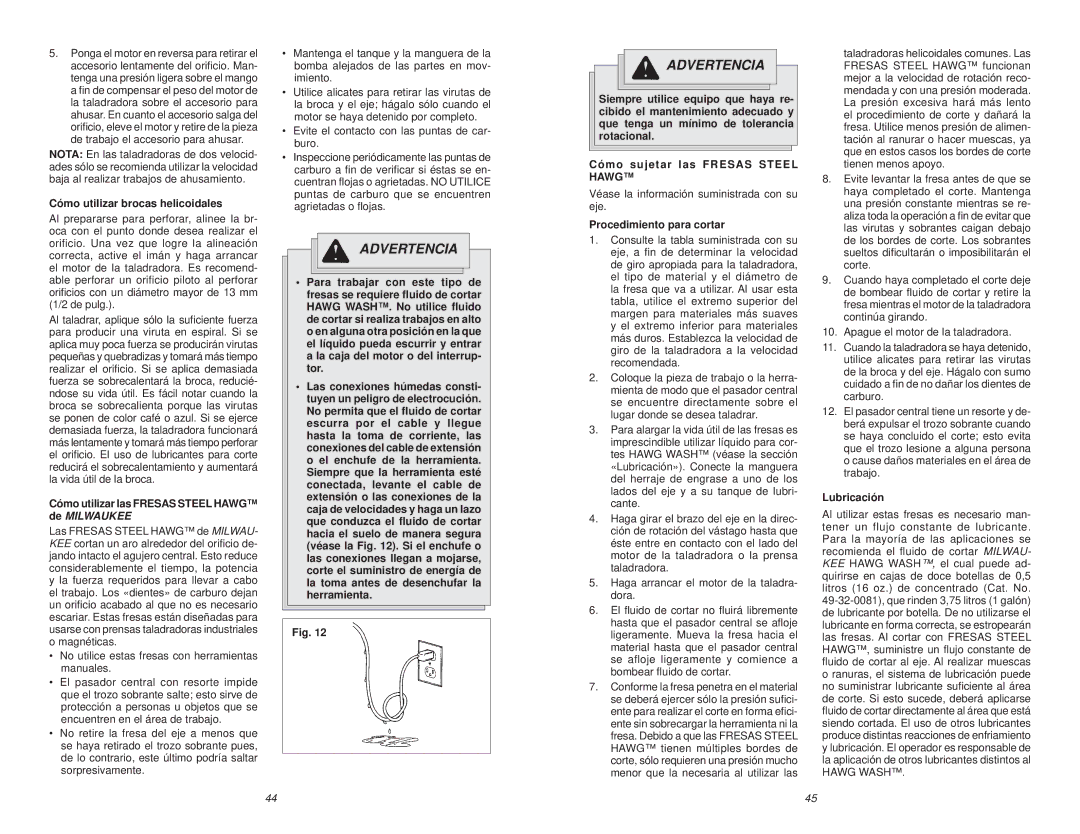

•Wet connections are shock hazards. Prevent cutting fluid from traveling along cord and contacting the out- let, extension cord connections or tool plug. Each time tool is plugged in, elevate extension cord or gang box connections and arrange a drip loop (See Fig. 12). If plug or connec- tions get wet, turn power off to outlet before unplugging tool.

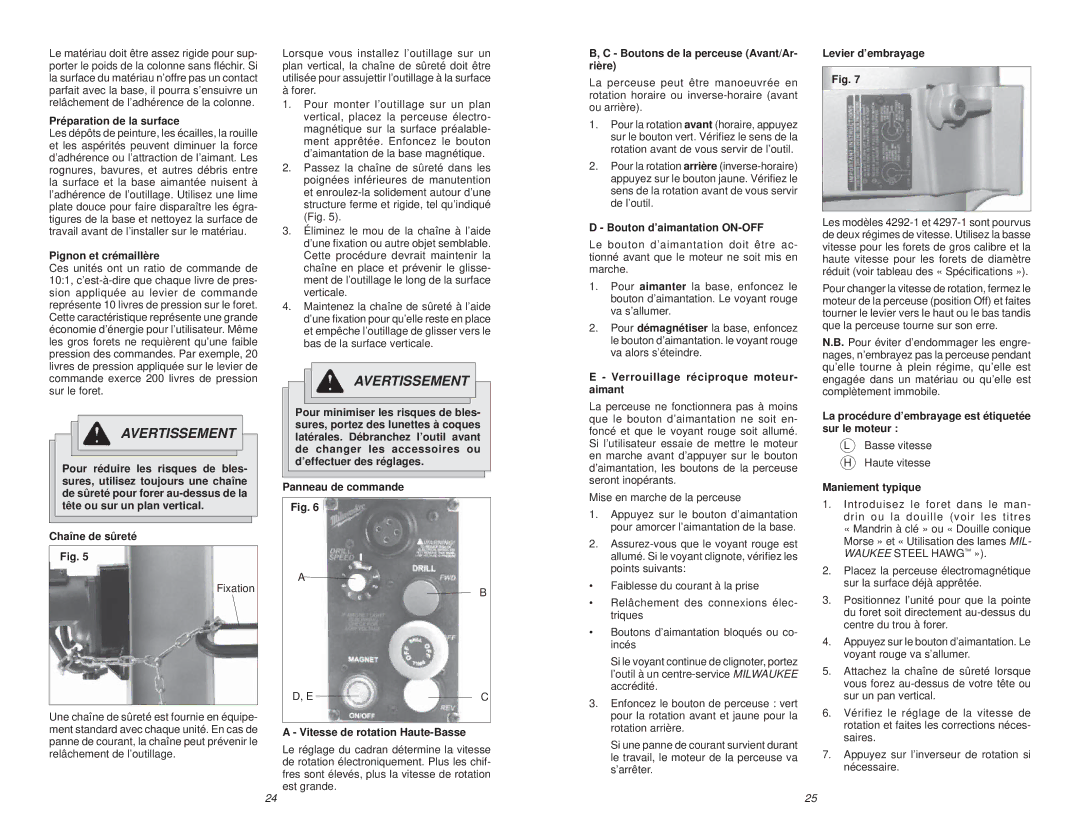

Fig. 12

WARNING

Always use well maintained equip- ment with minimum spindle run out.

Attaching MILWAUKEE STEEL HAWG™

CUTTERS

See the information supplied with your arbor.

Cutting Procedure

1.Refer to the chart supplied with the arbor to determine the proper drill rotating speed for the type of material and cutter diameter. When using this chart, use the upper end of the range for softer materials and the lower end for harder materials. Set the drill rotating speed to the recommended speed.

2.Position the workpiece or tool so that the center pin is directly over the desired drilling location.

3.The use of HAWG WASH™ cutting fluid is required for long life of these cutters (see "Lubrication"). Attach the hose to the oil fitting on the side of the arbor and to your lubricant reservoir.

4.Swing the arbor arm in the direction of the spindle rotation until it comes in contact with the side of the drill motor or drill press.

5.Start the drill motor.

6.Cutting fluid will not flow freely until the center pin is depressed slightly. Move the cutter towards the material until the center pin is depressed slightly and begin pumping cutting fluid.

7.When feeding the cutter into the materi- al, use only enough pressure to produce efficient cutting without overloading the tool or cutter. Because STEEL HAWG™ CUTTERS have multiple cutting edges, they require considerably less down- ward pressure than ordinary twist drills. STEEL HAWG™ CUTTERS work best at their recommended drill rotating speed and with moderate pressure. Excessive pressure will only slow the operation and damage the cutter. Use less feed pressure when slotting or notching because there is less support for the cutting edges in these situa- tions.

8.Avoid raising the cutter before the cut is complete. Keep constant pressure throughout the entire operation to prevent chips and cuttings from falling under the cutting edges. A loose cutting under the cutter can make cutting dif- ficult or impossible.

9.When the cut is completed, stop pump- ing cutting fluid, and withdraw the cutter while the drill motor is still rotating.

10.Turn the drill motor off.

11.When the drill has stopped, use a pli- ers to remove cuttings from the bit and arbor. Use care to avoid damaging the carbide teeth.

12.The center pin is spring loaded and should eject the slug when the cut is completed. Provide protection from fall- ing slugs for people or property below.

Lubrication

A continuous flow of lubricant is required with these cutters. MILWAUKEE HAWG WASH™ (cutting fluid) is recommended for most ap- plications. It is available in a case of twelve 16 oz. bottles of concentrate, Cat. No. 49-

12 | 13 |