HEPA Filter

(Manual Cleaning)

This HEPA filter removes 99.97% of the

Tools Needed | Qty |

OSHA Approved Respirator | ............................... 1 |

Safety Goggles | 1 |

Air Compressor | 1 |

Blowgun | 1 |

To clean the HEPA filter: |

|

1.DISCONNECT THE MACHINE FROM POWER, put on your respirator, and empty the dust drawer.

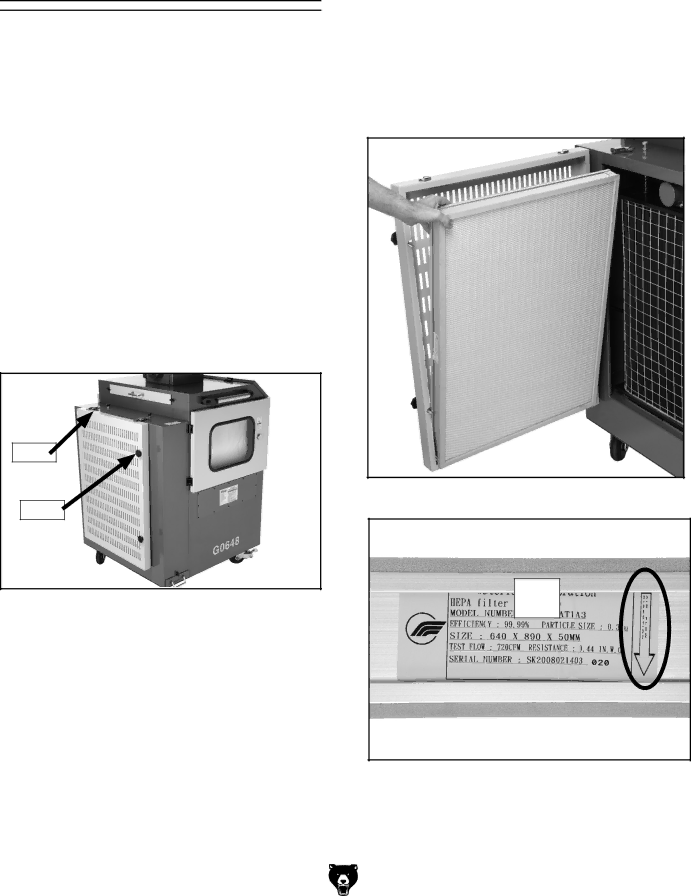

2.Unscrew the lock knobs, unlatch the HEPA filter housing, then open the filter housing (Figure 40).

Latch

Knob