ELECTRICAL

![]() WARNING:

WARNING:

To prevent possible electrical hazards, have a qualified electrician check the line if you are not certain that it is properly wired.

CHANGING MOTOR VOLTAGE

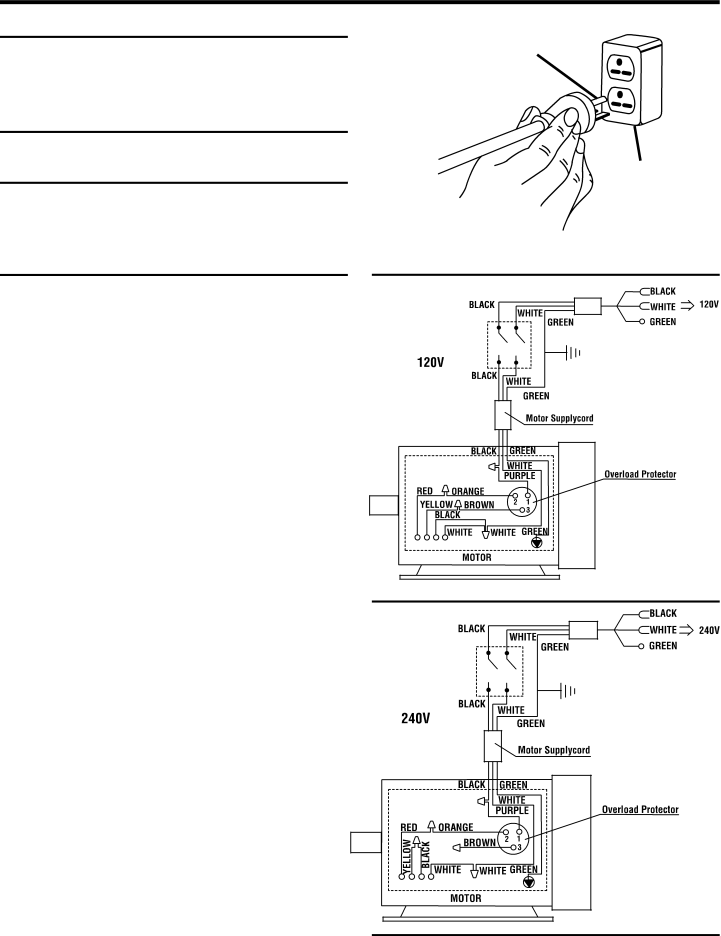

See Figures 2 - 4.

![]() WARNING:

WARNING:

Electric shock can kill. To reduce the risk of seri- ous personal injury, never connect plug to power source until all assembly steps are completed.

NOTE: The table saw is prewired at the factory for 120 V, 60 Hz. Use the following procedures to change motor voltage from 120 V to 240 V.

Unplug the saw.

Located on the top of the motor is the junction box. Remove the phillips screw at the back of the junction box then lift off the cover.

Remove and discard the electrical tape from the wire connectors. Remove wire connectors.

Reconnect the leads.

Reinstall the wire connectors and wrap each wire with two layers of new UL listed electrical tape.

Recheck your wiring with the wiring diagrams.

Reinstall the junction box cover using the phillips screw.

Cut off the 120 volt power cord plug and replace it with a

Connect the power cord white and black leads, respectively, to the "hot" plug blade terminals. Connect the power cord green grounding wire to the plug ground prong terminal.

Plug your table saw into a

GROUNDING

PIN

COVER OF

GROUNDED

OUTLET BOX

FOR USE WITH | Fig. 2 |

|

Fig. 3

Fig. 4

9