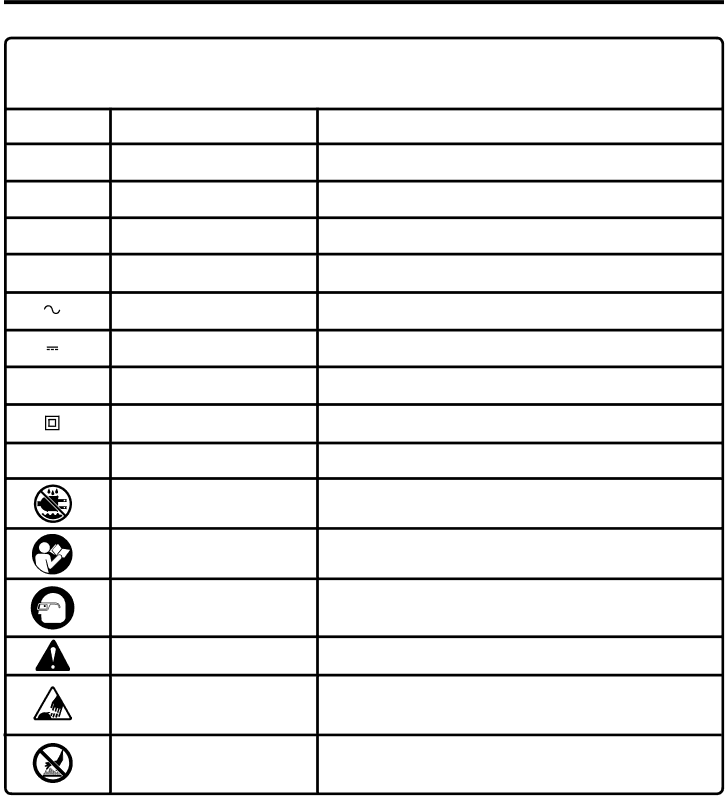

SYMBOLS

Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper interpreta- tion of these symbols will allow you to operate the tool better and safer.

SYMBOL | NAME | DESIGNATION/EXPLANATION |

V | Volts | Voltage |

A | Amperes | Current |

Hz | Hertz | Frequency (cycles per second) |

W | Watt | Power |

min | Minutes | Time |

| Alternating Current | Type of current |

| Direct Current | Type or a characteristic of current |

no | No Load Speed | Rotational speed, at no load |

| Class II Construction | |

.../min | Per Minute | Revolutions, strokes, surface speed, orbits etc., per minute |

| Wet Conditions Alert | Do not expose to rain or use in damp locations. |

| Read The Operator’s Manual | To reduce the risk of injury, user must read and understand |

| operator’s manual before using this product. | |

|

| |

| Eye Protection | Always wear safety goggles, safety glasses with side shields, or |

| a full face shield when operating this product. | |

|

| |

| Safety Alert | Precautions that involve your safety. |

| No Hands Symbol | Failure to keep your hands away from the blade will result in |

| serious personal injury. | |

|

| |

| Hot Surface | To reduce the risk of injury or damage, avoid contact with any |

| hot surface. | |

|

|

6