Repair

Alternator Removal and Replacement

NOTE: Replace alternator bearings after 2000 hours of operation. Order Part No. 24N706 Bearing Kit. Parts included in the kit are marked with a symbol (♦).

1.See Prepare the Gun for Service, page 39.

2.Remove the power supply/alternator assembly and disconnect the alternator. See Power Supply Removal and Replacement, page 45.

3.Measure resistance between the two outer terminals of the

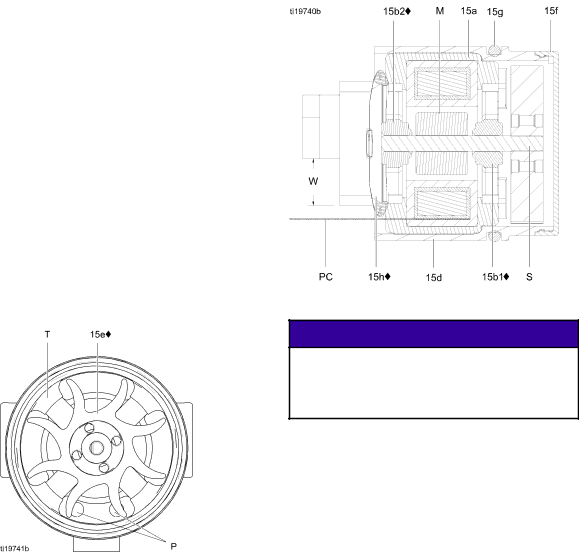

4.Using a flat blade screwdriver, pry the clip (15h) off the housing (15d). Remove the cap (15f), using a thin blade or screwdriver.

5.If necessary, rotate the fan (15e) so its blades clear the four bearing tabs (T) of the housing (15d).

Figure 34 Fan Orientation

6.Push the fan and coil assembly (15a) out the front of the housing (15d).

Figure 35 Alternator Cross-Section

NOTICE

Do not scratch or damage the magnet (M) or shaft (S). Do not pinch or damage the 3–wire connector (PC) when disassembling and reassembling the bearings.

7.Hold the coil assembly (15a) on a workbench with the fan end facing up. Using a wide blade screwdriver, pry the fan (15e) off the shaft (S).

8.Remove the top bearing (15b2).

9.Remove the bottom bearing (15b1).

10.Install the new bottom bearing (15b1♦) on the long end of the shaft (S). The flatter side of the bearing must face away from the magnet (M).

Install in the coil (15a) so the bearing blades are flush with the surface of the coil.

11.Press the new top bearing (15b2♦) onto the short end of the shaft so the bearing blades are flush with the surface of the coil (15a). The flatter side of the bearing must face away from the coil.

46 | 3A2495C |