Installation

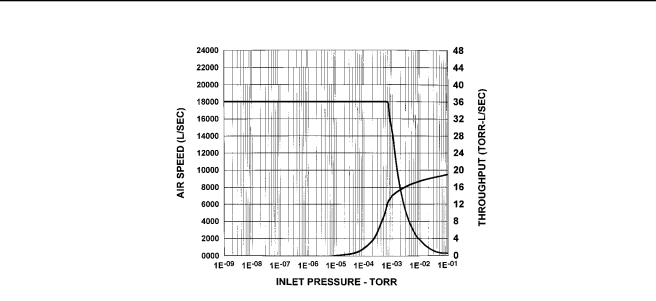

Figure 1-1. Speed and Throughput Curves – HS-20 Diffusion Pump

PHYSICAL SPECIFICATIONS (See Figure |

|

|

| |||||

Flange dimensions (inches): |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| ASA |

| ISO 630k | ISO 160k | ||

|

|

| Inlet |

| Foreline | Inlet | Foreline | |

OD |

|

| 27.50 |

| 9.0 | 27.17 | 7.09 |

|

ID |

|

| 21.25 |

| 5.06 | 21.25 | 5.06 |

|

Thickness |

| 1.12 |

| 0.75 | 0.78 | 0.47 |

| |

Bolt Circle |

| 25.0 |

| 7.5 |

|

|

| |

|

|

|

| |||||

No. of Holes |

| 20.0 |

| 8.0 | Requires | Requires |

| |

Size of Holes |

| 1.25 |

| 0.75 |

| |||

|

|

|

|

|

| Centering Ring (not | Centering Ring (not |

|

Orientation |

| Straddle center line | ||||||

| included with pump) | included with pump) |

| |||||

Gasket Groove ID |

| 21.625 |

| 5.31 |

|

|

| |

| wide |

| 0.48 |

| 0.375 |

|

|

|

| deep |

| 0.25 |

| 0.09 |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

Height | 48 inches; allow additional |

| 8 inches (min) for heater removal |

Jet Assembly

Foreline | Stacked disk and ring | |

Baffle |

|

|

Cold Cap | ||

Water | 1⁄4 | FPT body and foreline |

Connections | 3⁄8 | quick cool coils |

Thermal | Upper set at 185°F (29°C) | |

Switches | Lower set at 390°F (93°C) | |

Materials | Body: Mild steel |

| Flanges: Mild steel |

| Jet Assembly: Aluminum |

| Foreline Baffle: Stainless Steel |

| Cooling Coils: Copper |

| Quick Cool Coils: Stainless Steel |

| Cold Cap: Copper |

Weight | 500 pounds |

Shipping | 580 pounds |

Weight |

|