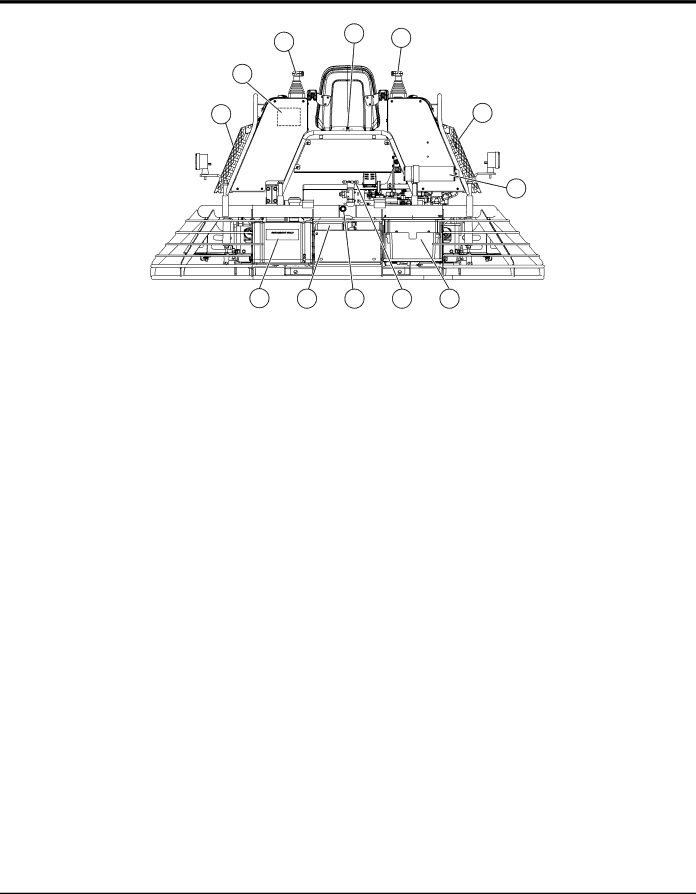

components

29

38

31

39 30

31

32 |

37 | 36 | 35 | 34 | 33 |

Figure 5. Components (Rear)

17.Pitch Mode Switch — Sets the mode of operation of the blade pitch system to either auto or manual.

18.Fuel Pump— Provides fuel flow to injection pump.

19.Blade Pitch Control (Twin Pitch) — Adjusts the pitch on both rotors simultaneously but

20.Blade Pitch Control Switch (left side) — Adjusts the left side blade pitch independently of the right side.

21.Hydraulic Reservoir — Part of frame. Holds hydraulic oil necessary for pump operation.

22.Spray Nozzles — Spray nozzle for retardant.Two spray nozzles are supplied with this unit.

23.Overflow Bottle — (Behind grill guard.) Supplies water or coolant to the radiator when radiator water or coolant level is low. Fill to indicated level as shown on bottle.

24.Fuel Gauge/Filler Cap — Indicates the amount of fuel in the fuel tank. Remove this cap to add fuel.

25.Toolbox Compartment — Storage for tools.

26.Fuse Box — Contains fuses for control electronics.

27.Relays — Relays for lights and safety bypass switch.

28.Light Switch — When activated, turns on six halogen lights. Lights offer better visibility when working indoors

29.Steering Control (left side) — Allows the unit to move in a forward or reverse direction only.

30.Steering Control (right side) — Allows the unit to move in either a forward, reverse left or right direction.

31.Grill Guards (left and right) — Protects operator from moving components. Remove for maintenance access.

32.Documentation Canister — Storage for documentation and other information regarding the trowel.

33.Battery — Provides +12V DC to the electrical system.

34.Hydraulic Oil Filler Cap — Remove this cap to add hydraulic oil. Open ONLY when system is cooled down and all expanded oil has returned to the reservoir.

35.Hydraulic Oil Sight Glass — Indicates the level of the hydraulic oil in the reservoir.

36.Hydraulic Suction Filter — Filters hydraulic fluid prior to entering the system. (10 Micron absolute synthetic media.)

37.Retardant SprayTank — Holds 5 gallons of retardant, water, or other liquid.

38.Hydraulic Oil Expansion Tank — Accommodates expanding hydraulic oil as it gets hot. The oil gravity flows back to the reservoir as it cools down, therefore NEVER open the Hydraulic Oil Filler Cap when the system is warm and the oil has expanded.

39.Safety Bypass Switch — The trowel will not move unless an operator is sitting on the seat. The weight of an operator activates the switch allowing the rotors to turn.

STXD6i